Tungsten-acidified cerium-doped zirconium dioxide coated titanium dioxide solid super acid filler

A solid super acid, zirconium dioxide technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can improve the anti-pollution ability and improve the photocatalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

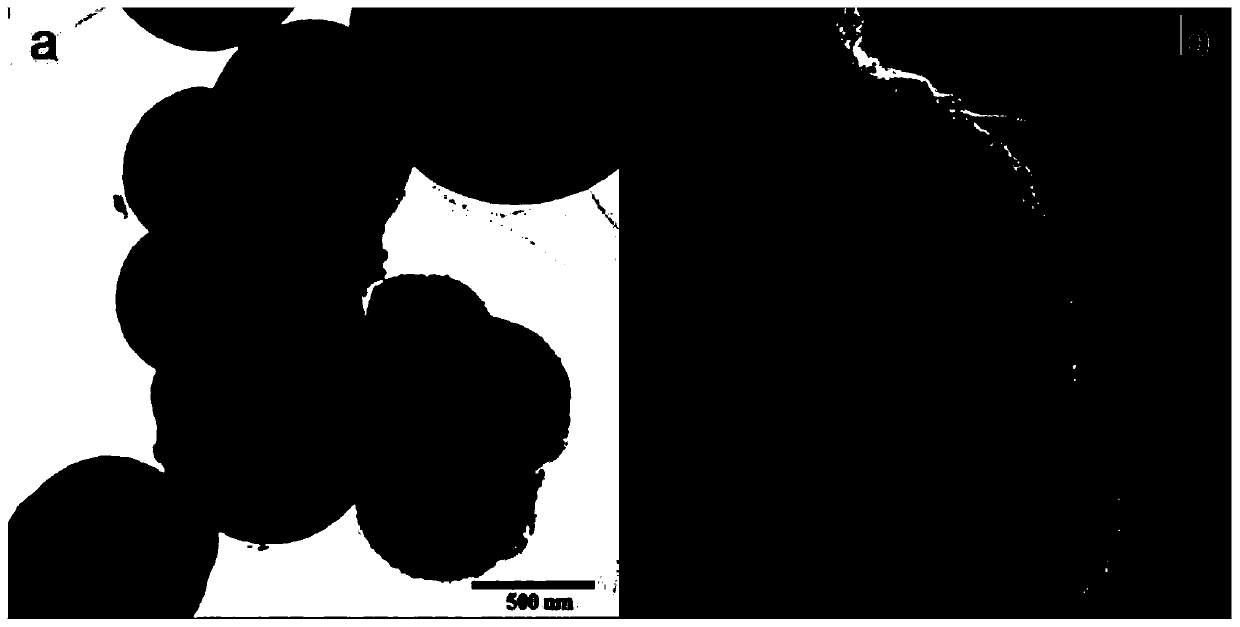

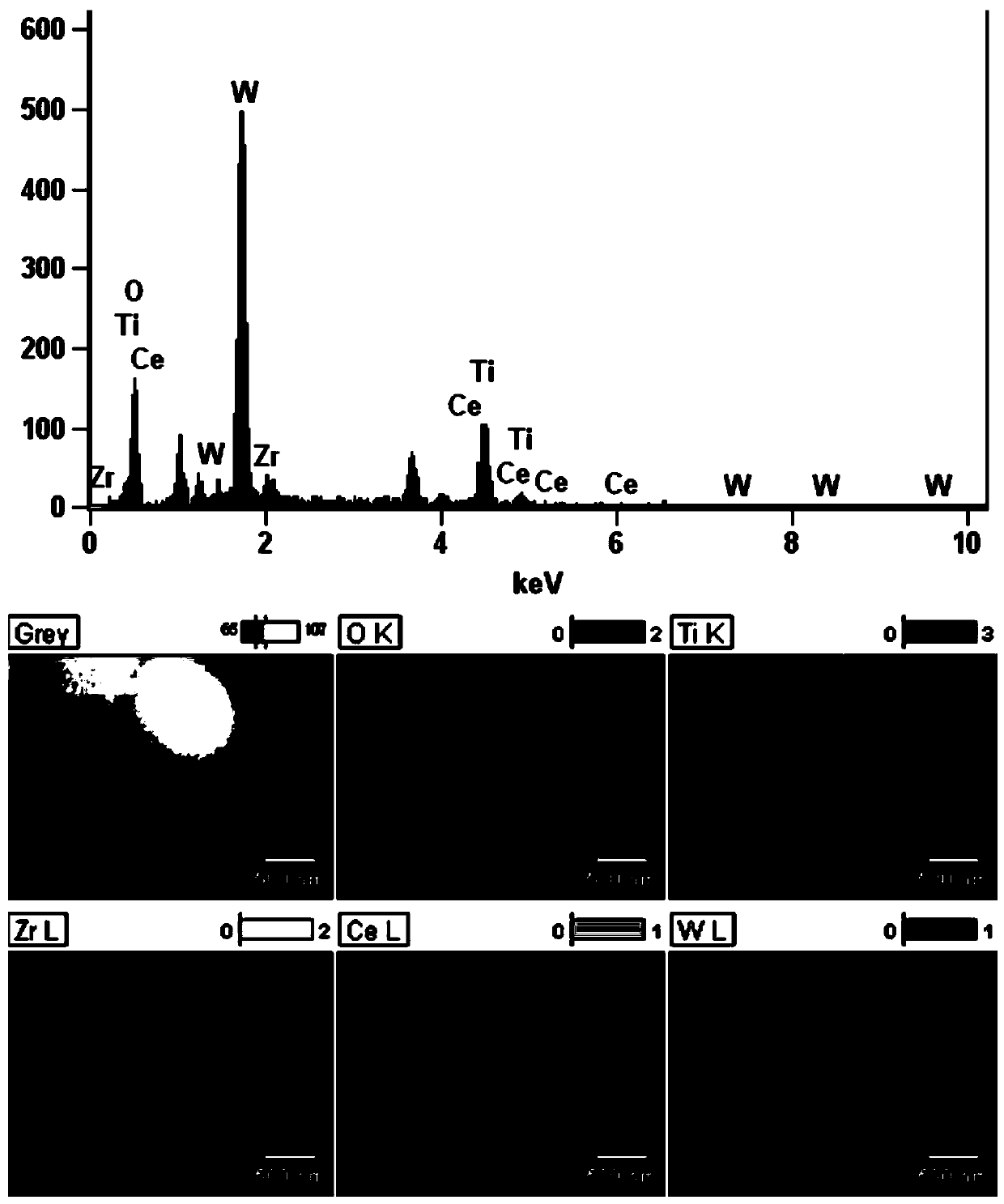

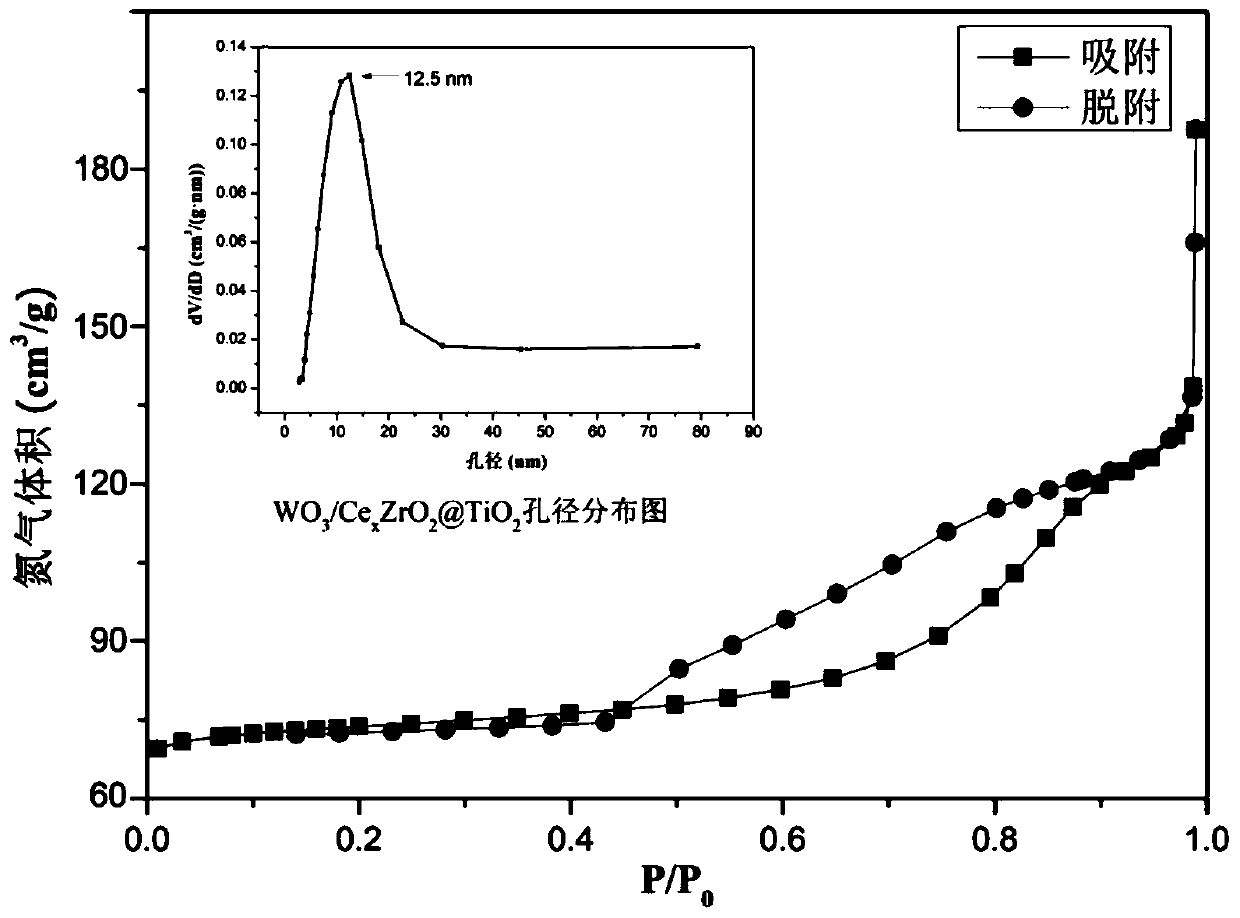

Image

Examples

Embodiment 1

[0019] The preparation method of cerium tungstate-doped zirconia-coated titanium dioxide solid superacid filler comprises the following steps:

[0020] 1) Take 0.2gTiO 2 , mixed with 100mL of anhydrous methanol, stirred evenly, transferred to a container containing 400mL of deionized water, and then added 0.1g of lignin amine to it, ultrasonically dispersed for 45min to obtain a dispersion, took it out, and added concentrated ammonia water to the dispersion, Let the pH be 10, add 80mL of solution 1 at a feeding rate of 10mL / min, stir for 3h, stop stirring, leave to age at room temperature for 4.5h, centrifuge, filter, wash with deionized water until neutral, take out the filter cake ; Vacuum drying at 60°C for 8h; Grinding and calcining at 550°C for 3h to obtain a light yellow precursor; 2 ·8H 2 O and 0.0025gCe(SO 4 ) 2 4H 2 O was dissolved in deionized water to make the total volume 80mL, and mixed evenly to prepare;

[0021] 2) Immerse the precursor in 3g / L ammonium tu...

Embodiment 2

[0027] The preparation method of cerium tungstate-doped zirconia-coated titanium dioxide solid superacid filler comprises the following steps:

[0028] 1) Take 0.1gTiO 2 , mixed with 20mL of anhydrous methanol, stirred evenly, transferred to a container containing 100mL of deionized water, and then added 0.01g of lignin amine to it, ultrasonically dispersed for 30min to obtain a dispersion, took it out, and added concentrated ammonia water to the dispersion, Make the pH to 9, add 20mL of solution 1 at a feeding rate of 1mL / min, stir for 2h, stop stirring, leave to age at room temperature for 4h, centrifuge, filter, wash with deionized water until neutral, and take out the filter cake; Vacuum drying at 50°C for 5h; Grinding and calcining at 500°C for 4h to obtain a light yellow precursor; the first solution is to mix 0.1428g ZrOCl 2 ·8H 2 O and 0.0144g Ce(SO 4 ) 2 4H 2 O was dissolved in deionized water to make the total volume 20mL, and mixed evenly to prepare;

[0029] ...

Embodiment 3

[0034] The preparation method of cerium tungstate-doped zirconia-coated titanium dioxide solid superacid filler comprises the following steps:

[0035] 1) Take 5gTiO 2 , mixed with 200mL of anhydrous methanol, stirred evenly, transferred to a container containing 700mL of deionized water, and then added 0.5g of lignin amine to it, ultrasonically dispersed for 60min to obtain a dispersion, took it out, and added concentrated ammonia water to the dispersion, Make the pH to 11, add 200mL of solution 1 at a feeding rate of 20mL / min, stir for 4 hours, stop stirring, leave to age at room temperature for 5 hours, centrifuge, filter, wash with deionized water until neutral, and take out the filter cake; Vacuum drying at 70°C for 10 hours; finely ground, calcined at 600°C for 2 hours to obtain a light yellow precursor; the first solution is to mix 7.296g of ZrOCl 2 ·8H 2 O and 5.4g Ce(SO 4 ) 2 4H 2 O was dissolved in deionized water to make the total volume 200mL, and mixed evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com