Dielectric waveguide filter

A dielectric waveguide and filter technology, applied in the field of dielectric waveguide filters, can solve problems such as poor product consistency, leakage of silver at the bottom of holes, and fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

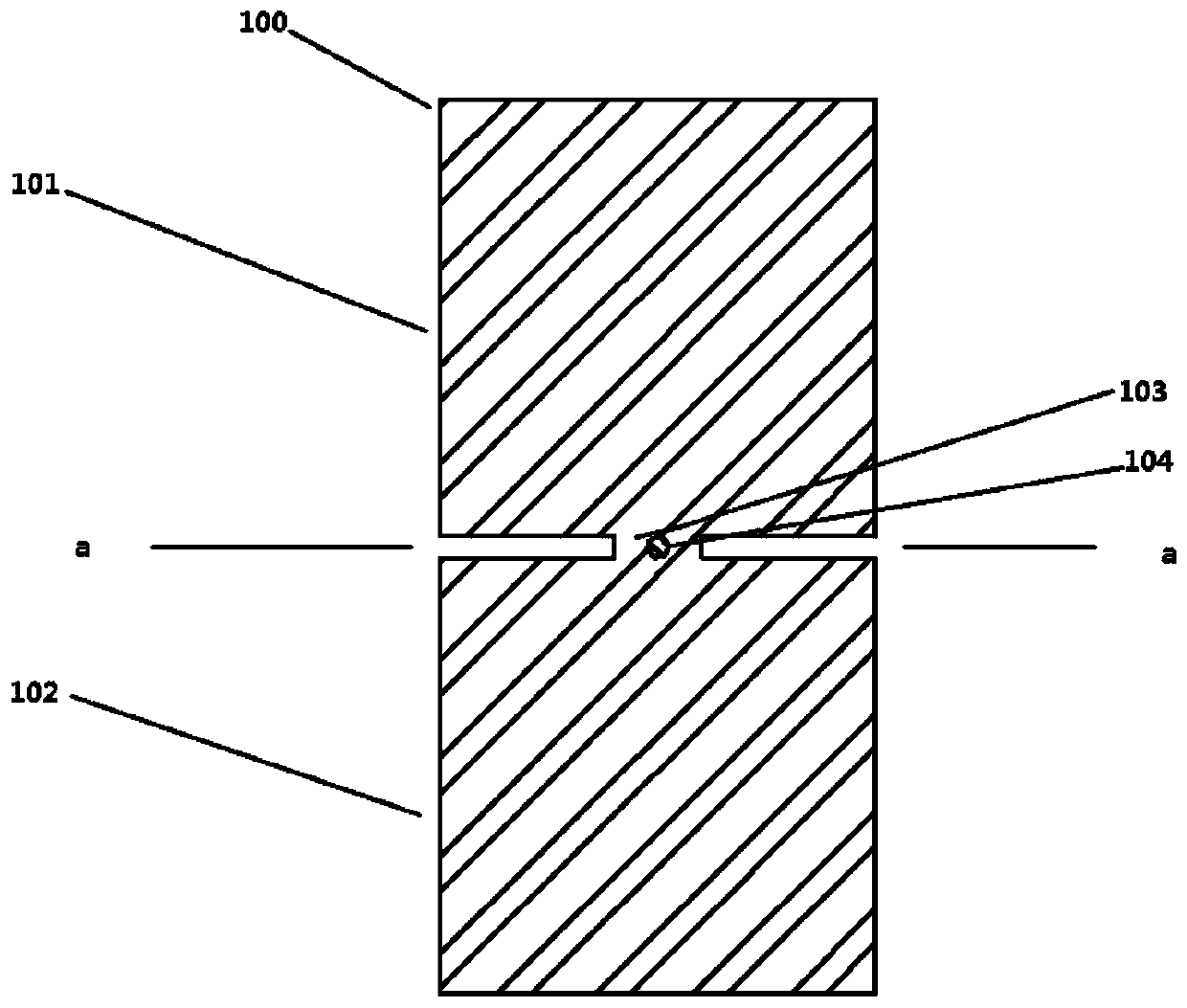

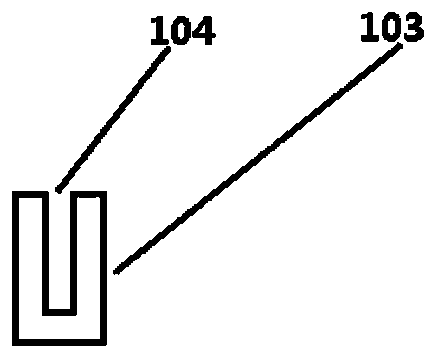

[0043] Embodiment 1 provides a solution including two dielectric resonators, such as image 3 with Figure 4 As shown, the dielectric waveguide filter includes a dielectric resonator 201 and a dielectric resonator 202 , the dielectric resonator 201 and the dielectric resonator 202 are connected through an H-shaped coupling structure 205 , and the H-shaped coupling structure 205 has deep grooves 203 and shallow grooves 204 .

[0044] In the above-mentioned embodiment, the length and width of the deep groove 203 and the shallow groove 204 are the same, the depth of the deep groove 203 exceeds half of the overall height of the H-shaped coupling structure 205, and the top, bottom and sides of the H-shaped coupling structure 205 are uniform. It is flush with the dielectric resonator 201 and the dielectric resonator 202 .

Embodiment 2

[0046] Different from Embodiment 1, the dielectric waveguide filter in Embodiment 2 includes four dielectric resonators, such as Figure 5 As shown, dielectric resonator 302, dielectric resonator 304, dielectric resonator 305, and dielectric resonator 306 are respectively, wherein, 301 is an input and output connector, and dielectric resonator 302 and dielectric resonator 304 are connected by a window-shaped coupling structure 303 forms the main coupling, between the dielectric resonator 304 and the dielectric resonator 305 and between the dielectric resonator 305 and the dielectric resonator 306 adopts the same coupling structure as the window-shaped coupling structure 303, between the dielectric resonator 302 and the dielectric resonator 306 Between, there is an H-shaped coupling structure 307, the dielectric waveguide filter can form a transmission zero at the high end of the passband and the low end of the passband, as can be seen from the figure, the window-shaped coupling...

Embodiment 3

[0048] The above two embodiments provide the situation of an even number of dielectric resonators. In the third embodiment, a situation of a dielectric waveguide filter including three dielectric resonators is provided, such as Image 6 As shown, the dielectric waveguide filter includes a dielectric resonator 402, a dielectric resonator 403 and a dielectric resonator 404, 401 is an input and output connector, and between the dielectric resonator 402 and the dielectric resonator 403 404 share the window-shaped coupling structure 406 to form the main coupling, and realize a window-shaped coupling structure to couple three sequentially. Between the dielectric resonator 402 and the dielectric resonator 404, there is an H-shaped coupling structure 405. The dielectric Waveguide filters can form a transmission zero at the low end of the passband.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com