Electron beam cured high-wear-resistant scratch-resistant white coating and preparation method and construction method thereof

A technology of electron beam curing and high wear resistance, applied in the field of coatings, it can solve the problems of poor coating adhesion, insufficient curing, residual photoinitiator, etc., and achieve excellent hiding power, good wear resistance, and excellent scratch resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

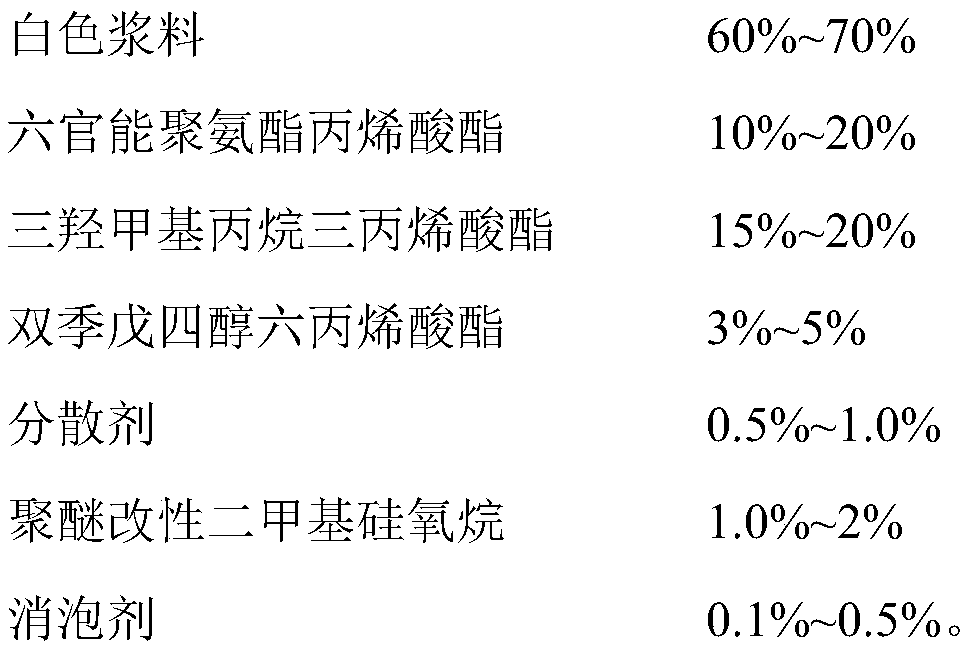

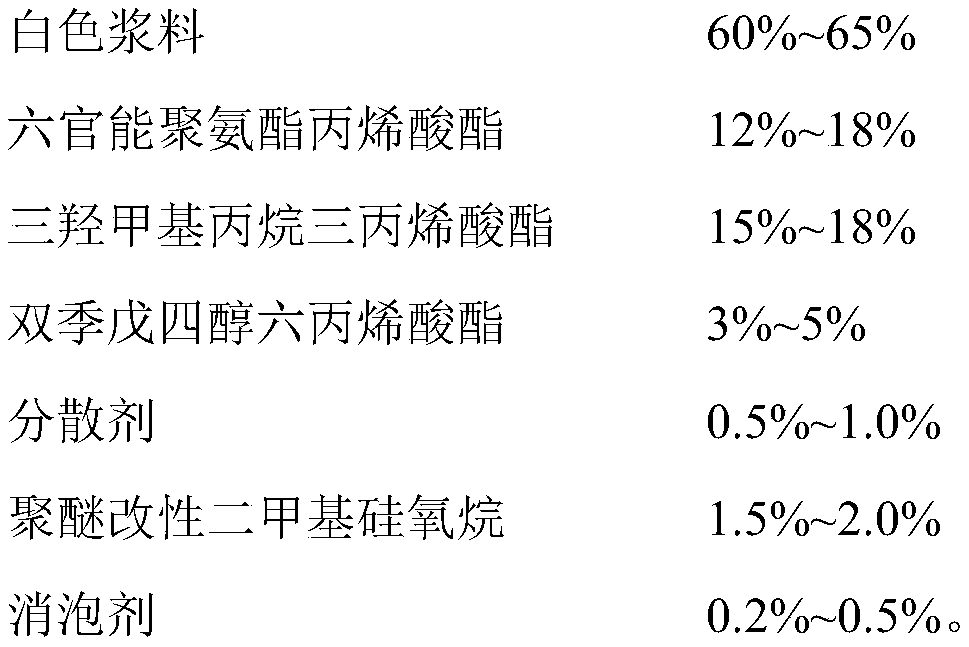

[0041] The highly wear-resistant and scratch-resistant white coating of a kind of electron beam curing of the present embodiment comprises the following components by weight: white slurry 600.0g, hexafunctional urethane acrylate UX-5400W 150.0g, trimethylolpropane triacrylic acid 174.0 g of ester, 50.0 g of dipentaerythritol hexaacrylate, 5.0 g of dispersant BYK163, 20.0 g of polyether-modified dimethylsiloxane BYKUV3510, and 1.0 g of defoamer BYK055.

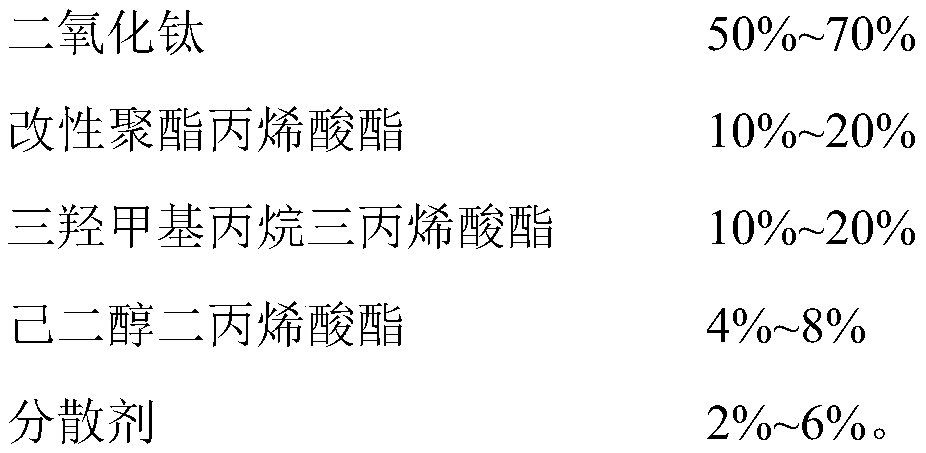

[0042]Among them, the white slurry includes the following raw materials in terms of mass percentage: 60% of titanium dioxide, 15% of modified polyester acrylate 6342, 15% of trimethylolpropane triacrylate, 6% of hexanediol diacrylate, and dispersant BYK163 4%.

[0043] Wherein, titanium dioxide is rutile titanium dioxide; the grain size of rutile titanium dioxide in the present embodiment is 0.3 μm, specific gravity 4.0g / cm 3 .

[0044] The preparation method of the high wear-resistant and scratch-resistant white coating of a...

Embodiment 2

[0049] The highly wear-resistant and scratch-resistant white paint of a kind of electron beam curing of the present embodiment comprises the following components by weight: white slurry 620.0g, hexafunctional urethane acrylate UX-5400W 160.0g, trimethylolpropane triacrylic acid 154.0 g of ester, 40.0 g of dipentaerythritol hexaacrylate, 5.0 g of dispersant BYK163, 20.0 g of polyether-modified dimethylsiloxane BYKUV3510, and 1.0 g of defoamer BYK055.

[0050] Among them, the white slurry includes the following raw materials in terms of mass percentage: 50% titanium dioxide, 20% modified polyester acrylate 6342, 20% trimethylolpropane triacrylate, 8% hexanediol diacrylate, dispersant BYK163 2%.

[0051] Wherein, titanium dioxide is rutile titanium dioxide; the grain size of rutile titanium dioxide in the present embodiment is 0.2 μm, specific gravity 3.0g / cm 3 .

[0052] The preparation method of the high wear-resistant and scratch-resistant white coating of above-mentioned a ...

Embodiment 3

[0057] The highly wear-resistant and scratch-resistant white coating of a kind of electron beam curing of the present embodiment comprises the following components by weight: white slurry 650.0g, hexafunctional urethane acrylate UX-5400W 130.0g, trimethylolpropane triacrylic acid 149.0 g of ester, 45.0 g of dipentaerythritol hexaacrylate, 5.0 g of dispersant BYK163, 20.0 g of polyether-modified dimethylsiloxane BYKUV3510, and 1.0 g of defoamer BYK055.

[0058] Among them, the white slurry includes the following raw materials in terms of mass percentage: 70% of titanium dioxide, 10% of modified polyester acrylate 6342, 10% of trimethylolpropane triacrylate, 5% of hexanediol diacrylate, and dispersant BYK163 5%.

[0059] Wherein, titanium dioxide is rutile titanium dioxide; the grain size of rutile titanium dioxide in the present embodiment is 0.4 μm, specific gravity 5.0g / cm 3 .

[0060] The preparation method of the high wear-resistant and scratch-resistant white coating of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com