High-temperature heating film and preparation method thereof

A technology of heating film and high temperature, applied in the direction of heating element materials, etc., can solve the problem of low working temperature of heating film, and achieve the effect of fast heat conduction, rapid temperature rise and high heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

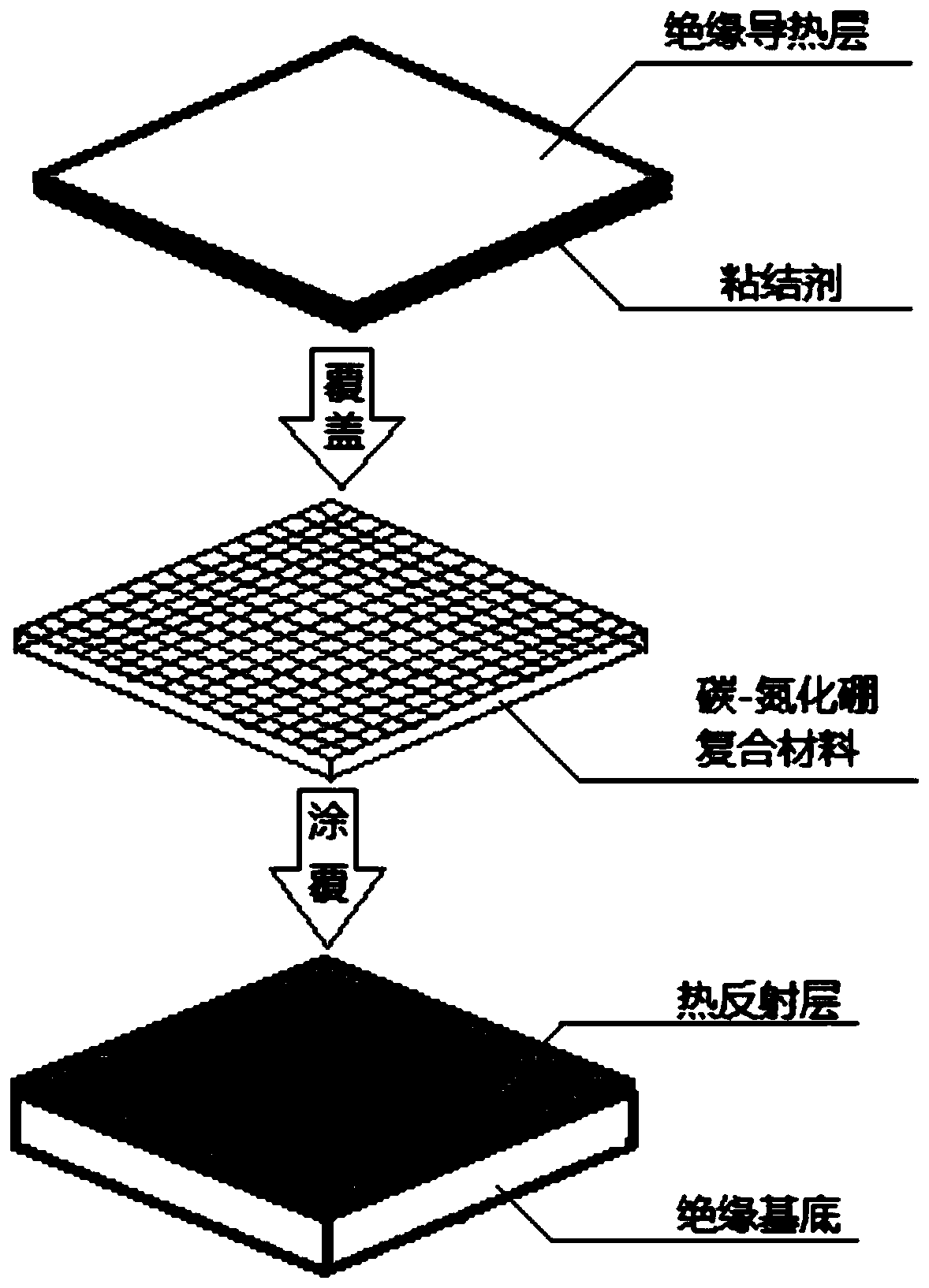

[0031] A method for preparing a high-temperature heating film of the present invention comprises the following steps:

[0032] S1, attaching a reflective layer on the insulating substrate;

[0033] The insulating substrate is a porous material, including one or more combinations of glass fiber cloth, glass, glass ceramics, ultrafine glass wool, high silica wool, and airgel felt.

[0034] The reflective layer is heat reflective material, including gold, silver, copper, nickel, aluminum foil or metal-plated polyester or polyimide film.

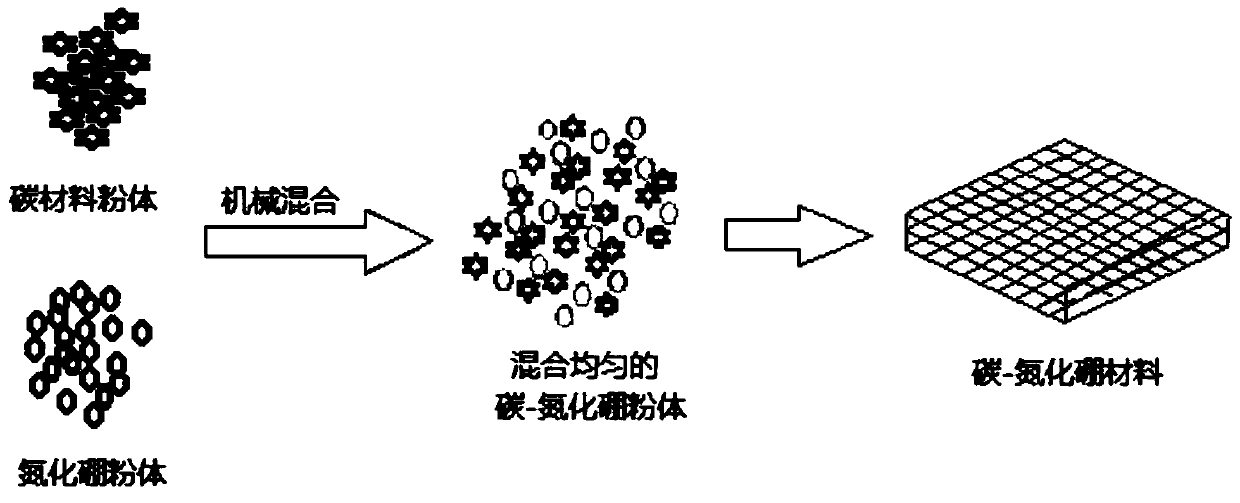

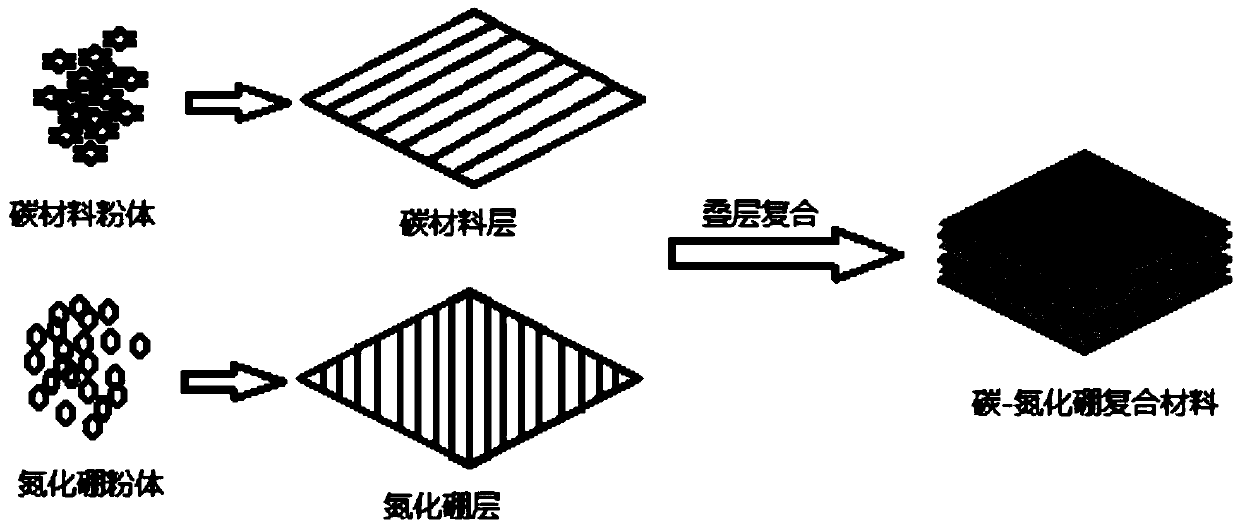

[0035] S2, compounding the carbon raw material and boron nitride in proportion to obtain a carbon-boron nitride composite material;

[0036] The carbon raw material is one or more combinations of graphite microcrystals, carbon crystals, graphene, conductive carbon, porous carbon, hollow carbon spheres, carbon nanotubes, and carbon fibers.

[0037] After the carbon raw material is compounded with the boron nitride, the mass proportion of the ca...

Embodiment 1

[0046] 1. Select glass-ceramics as the substrate, silver-plated polyimide as the reflective layer, and coat a layer of polyimide film on the glass-ceramics;

[0047] 2. Graphene and boron nitride are evenly compounded in a mass ratio of 4:1, and mechanically mixed to obtain a graphene-boron nitride composite material;

[0048] 3. Coat the graphene-boron nitride composite material on the polyimide film in step 1 as the heating layer, and weld metal copper wires on both sides of the heating layer as the positive and negative electrodes;

[0049] 4. Cover the heat-generating layer with an insulating and heat-conducting layer to prepare a composite high-temperature heating film.

[0050] The positive and negative poles were connected to 220V voltage, and the power was turned on for 30 seconds. The surface temperature of the film was measured to be 100°C by an infrared temperature tester.

Embodiment 2

[0052] 1. Select glass-ceramics as the substrate, silver-plated polyimide as the reflective layer, and coat a layer of polyimide film on the glass-ceramics;

[0053] 2. Graphene and boron nitride are stacked and compounded at a mass ratio of 1:1, wherein the bottom layer is a graphene layer and the top layer is a boron nitride layer to obtain a graphene-boron nitride composite material;

[0054] 3. Coat the graphene-boron nitride composite material on the polyimide film in step 1 as the heating layer, and weld metal copper wires on both sides of the heating layer as the positive and negative electrodes;

[0055] 4. Cover the heat-generating layer with an insulating and heat-conducting layer to prepare a composite high-temperature heating film.

[0056]The positive and negative poles were connected to 220V voltage, and the power was turned on for 30 seconds. The surface temperature of the film was measured to be 500°C by an infrared temperature tester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com