Magnetic nanoparticle composite film and preparation method thereof

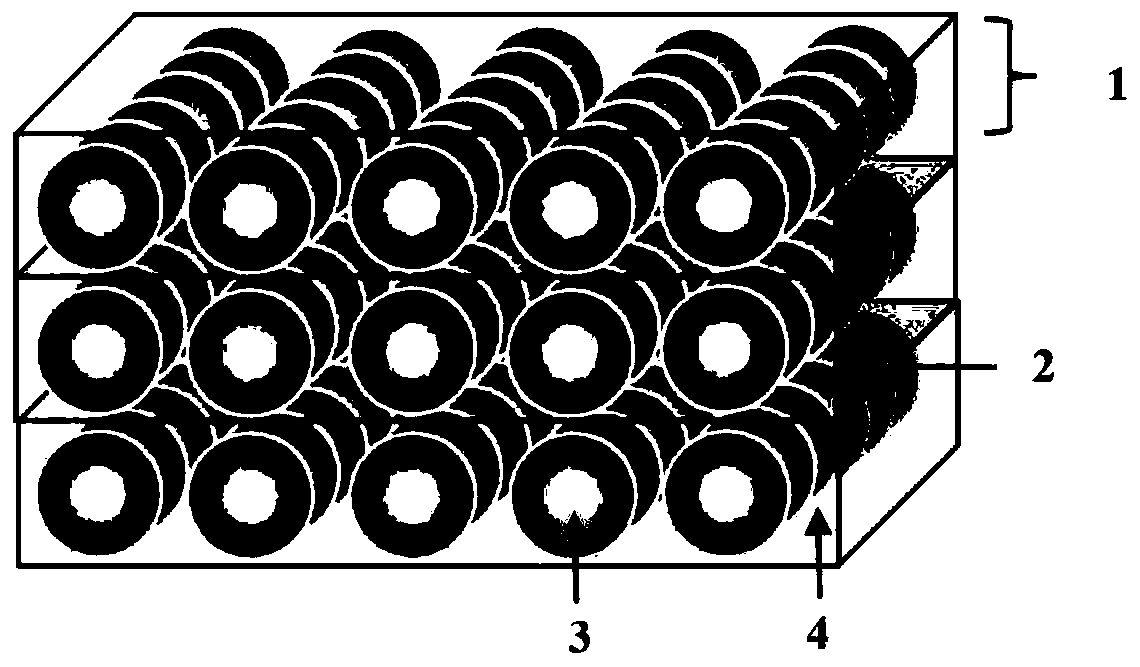

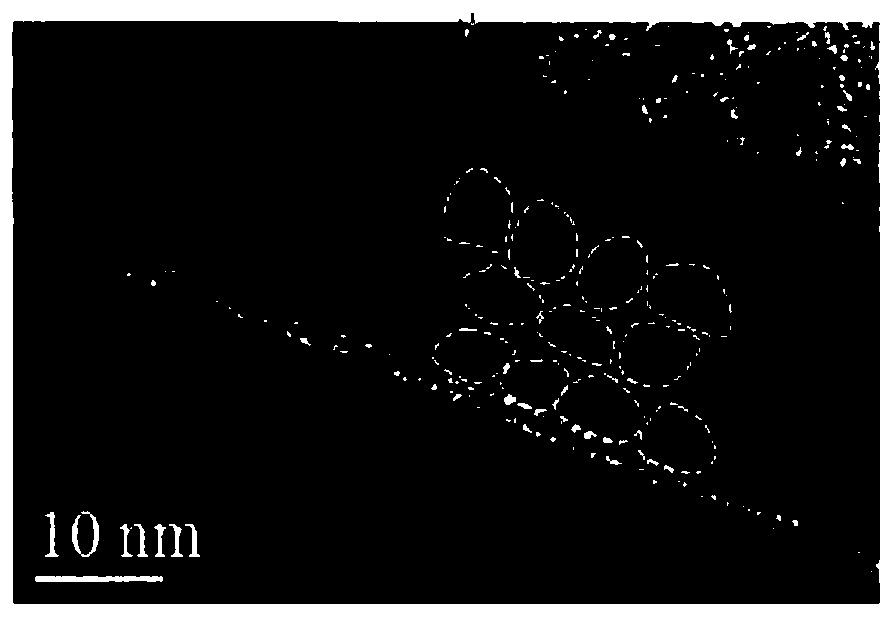

A magnetic nanoparticle and magnetic particle technology, applied in the direction of magnetic film, magnetic layer, magnetic object, etc., can solve the problems of particle size and distribution unevenness, nanoparticle composite film merged growth and difficult size control, etc., to achieve saturation magnetization Effects of improving, changing electrical properties, and reducing grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

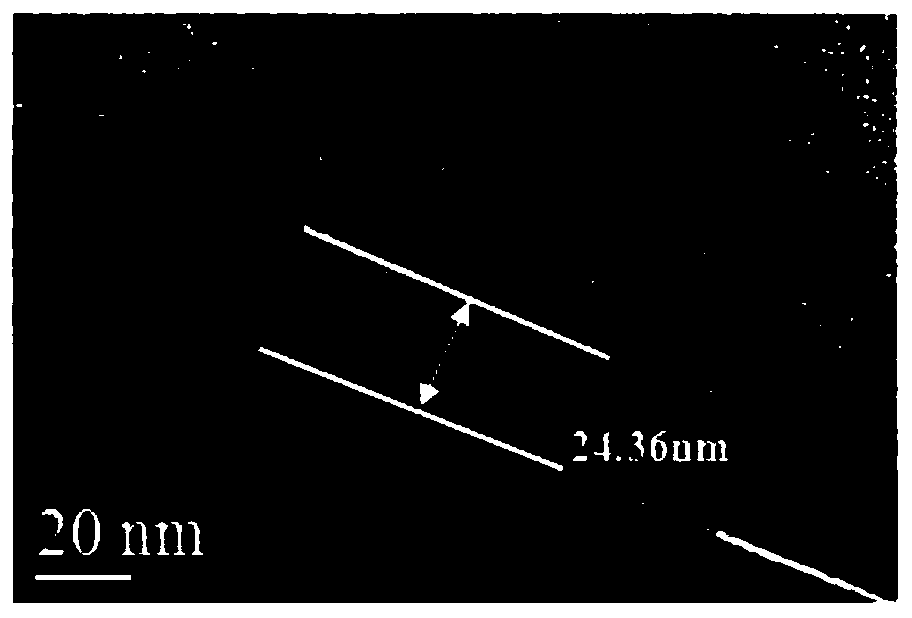

[0037] Fe 20 Ni 80 The evaporation rate at 1375°C is 0.916nm / min, and the evaporation rate of SiO at 982°C is 0.238nm / min. Fe 20 Ni 80 - The SiO layer is deposited at the above rate for 6min33s, and the insulating layer SiO is deposited at the above rate for 4min12s, alternately deposited 5 times. The preparation method of magnetic nano particle composite film comprises the following steps:

[0038] Step 1, substrate selection and pretreatment:

[0039] Select a polished silicon wafer with a surface roughness of less than 0.5nm and a crystal orientation of (100), ultrasonically clean the silicon wafer in acetone, deionized water, and alcohol solution for 15 minutes, and dry it with a high-purity argon high-pressure spray gun;

[0040] Step 2, raw material preparation:

[0041] The raw material used is Fe with a diameter of 1mm 20 Ni 80Granules and SiO particles with a diameter of 3mm, the purity of the raw materials is 99.999%. Put the two raw materials into two custom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com