Compound enzyme for preparing pulp, and preparation method and use method of compound enzyme

A composite enzyme and pulp technology, applied in textile and papermaking, fiber raw material processing and other directions, can solve the problems of difficult preservation of biological enzymes, unfavorable slurry purification, difficulty in effect control, etc., to improve the pretreatment effect, prolong the storage time, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0053] This experiment example is in the present invention, the determination experiment of the enzymatic activity of the enzymatic activity of the obtained compound solution to the immobilization of cellulase, hemicellulase, lignin degrading enzyme and pectinase by the enzyme carrier prepared in the invention by the applicant .

[0054] Experimental materials: 10mg / mL enzyme carrier solution, 10mg / mL cellulase solution, 10mg / mL hemicellulase solution, 10mg / mL lignin degrading enzyme solution, 10mg / mL pectinase solution, Ionized water, pH=6 phosphate buffer.

[0055] making process:

[0056] 1. Take 10g of enzyme carrier solution, put it into the reaction kettle, add 30g of pH=6 phosphate buffer solution, 100g of raw material enzyme solution, place at 5°C for 24h, take it out and wash it with phosphate buffer solution to obtain a composite solution;

[0057] 2. Shake the compound enzyme solution obtained in step 1 at room temperature for 20 minutes, centrifuge for 5 minutes,...

experiment example 2

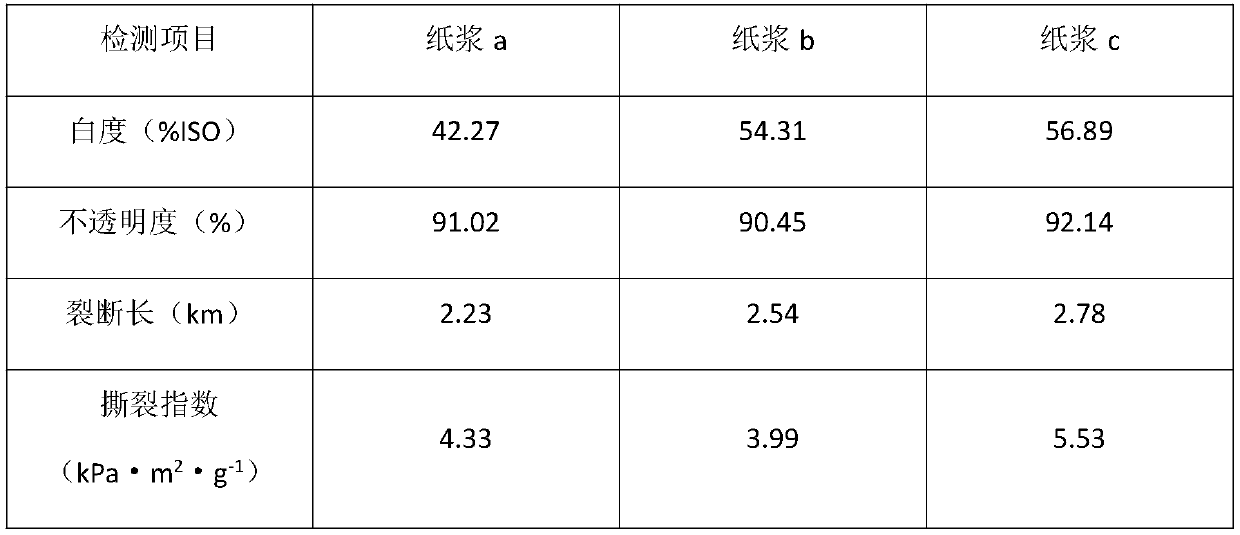

[0070] This experimental example is an experiment in which the applicant compares the effect of pulp pretreatment using pulping compound enzymes and other prior art pulp pretreatment effects in the present invention.

[0071] The pulp raw material used in this practical example is cotton stalk.

[0072] Preparation process a:

[0073] A kind of pulp is prepared by adopting the pretreatment process of the Chinese patent application (CN201710358393.7) in the prior art.

[0074] S1: Cut the cotton stalks into cotton stalk pieces, and transport them to the primary pretreatment immersion solution A. The primary pretreatment immersion solution A, in parts by weight, includes the following raw materials: 6 parts of alkylphenol polyoxyethylene ether, 0.5 parts of triethanolamine, 0.7 parts of stearic acid, 1 part of oleic acid, 1.2 parts of lauric acid, and 60 parts of water were soaked for 45 minutes under the action of ultrasonic waves, and then filtered to obtain the steeping mate...

experiment example 3

[0097] This experimental example is an experiment conducted by the applicant on the immobilization effect of hemicellulase and pectinase by using graphene oxide as a carrier in the present invention.

[0098] Experimental process A:

[0099] S1: Take 20kg of wood chips and place them in a sealed device, add a compound enzyme solution, the ratio of hemicellulase to pectinase in the graphene oxide compound enzyme solution is 5:1, and add deionized water to combine the enzyme solution with The slurry is mixed evenly, the dosage of hemicellulase is 5U / g absolute dry wood chips, and the consumption of pectinase is 1U / g absolute dry wood chips.

[0100] S2: react the solution obtained in step S1 at 45° C. for 1 hour, and slowly stir the material so that the material and the enzyme solution are fully mixed.

[0101] S3: heat the solution obtained in step S2 for 15 hours, and extract the prepared slurry.

[0102] S4: measuring the enzyme activity of the remaining reaction solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com