Tin cobalt alloy electroplating liquid with good deep plating capacity and electroplating method thereof

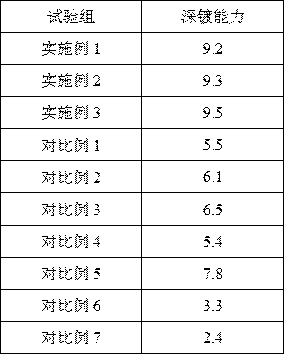

A tin-cobalt alloy and electroplating solution technology, which is applied in the field of electroplating, can solve problems such as poor deep plating ability, internal coating of long tube workpieces cannot meet the requirements, quality problems, etc., and achieve the effect of improving deep plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A tin-cobalt alloy electroplating solution with good deep-plating ability, its plating solution formula consists of:

[0023] Stannous chloride 40g / L

[0024] Cobalt chloride 40g / L

[0025] Potassium chloride 60g / L

[0026] EDTA disodium salt 12g / L

[0027] Sodium Potassium Tartrate 5g / L

[0028] Diphenylsulfonylimide 0.1g / L

[0029] Thiophene-2-sulfonic acid 0.3g / L

[0030] Coumarin 0.2g / L

[0031] N,N-Diethylaminopropargylamine 0.02g / L

[0032] The electroplating method of the tin-cobalt alloy electroplating solution: stainless steel is put into the electroplating solution as an anode, the workpiece is cleaned and activated according to the conventional plating pretreatment, and then electroplated with bright nickel, and the above-mentioned workpiece electroplated with bright nickel is put into the electroplating method of the present invention. The liquid is used as the cathode, and the current density is controlled to be 0.3-1.0 A / dm 2 , Plating bath tempera...

Embodiment 2

[0034] A tin-cobalt alloy electroplating solution with good deep-plating ability, its plating solution formula consists of:

[0035] Stannous chloride 50g / L

[0036] Cobalt chloride 30g / L

[0037] Potassium chloride 90g / L

[0038] EDTA disodium salt 10g / L

[0039] Sodium Potassium Tartrate 10 g / L

[0040] Diphenylsulfonylimide 0.05g / L

[0041] Thiophene-2-sulfonic acid 0.5g / L

[0042] Coumarin 0.1g / L

[0043] N,N-Diethylaminopropargylamine 0.05 g / L

[0044] The electroplating method of described tin-cobalt alloy electroplating solution is the same as embodiment 1.

Embodiment 3

[0046] A tin-cobalt alloy electroplating solution with good deep-plating ability, its plating solution formula consists of:

[0047] Stannous chloride 45g / L

[0048] Cobalt chloride 35g / L

[0049] Potassium chloride 70g / L

[0050] EDTA disodium salt 11g / L

[0051] Sodium Potassium Tartrate 6 g / L

[0052] Diphenylsulfonylimide 0.08g / L

[0053] Thiophene-2-sulfonic acid 0.4g / L

[0054] Coumarin 0.15g / L

[0055] N,N-Diethylaminopropargylamine 0.03g / L

[0056] The electroplating method of described tin-cobalt alloy electroplating solution is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com