A kind of ni-co-mn-sb-al magnetic refrigeration material and preparation method thereof

A ni-co-mn-sb-al, magnetic refrigeration material technology, applied in the direction of inorganic materials such as magnetism, can solve the problems of magnetic entropy change and magnetic refrigeration capacity, etc., to achieve larger magnetic entropy, increase magnetic entropy Variable, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

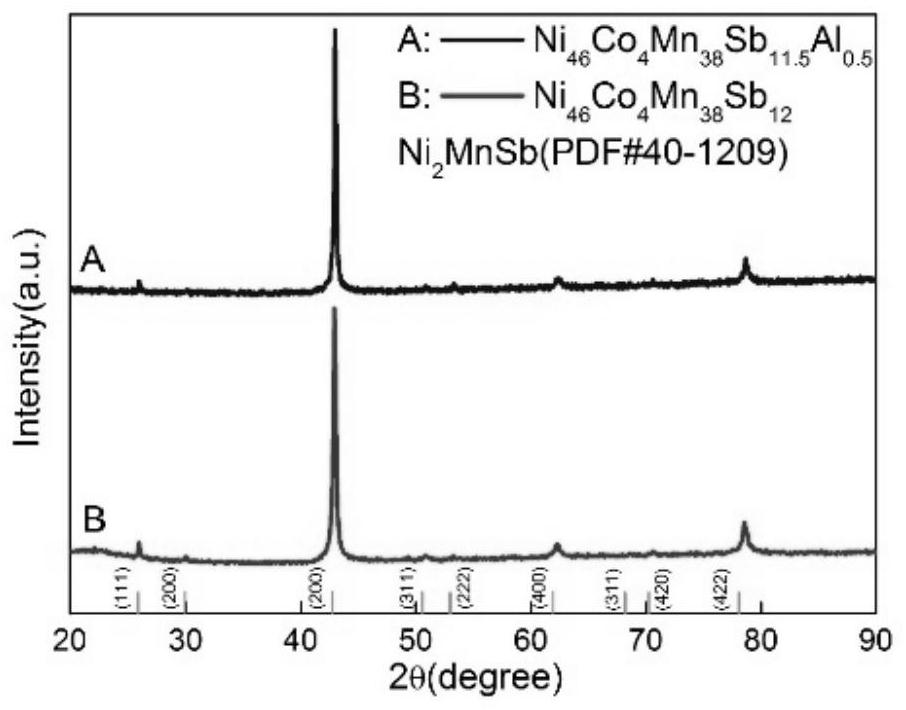

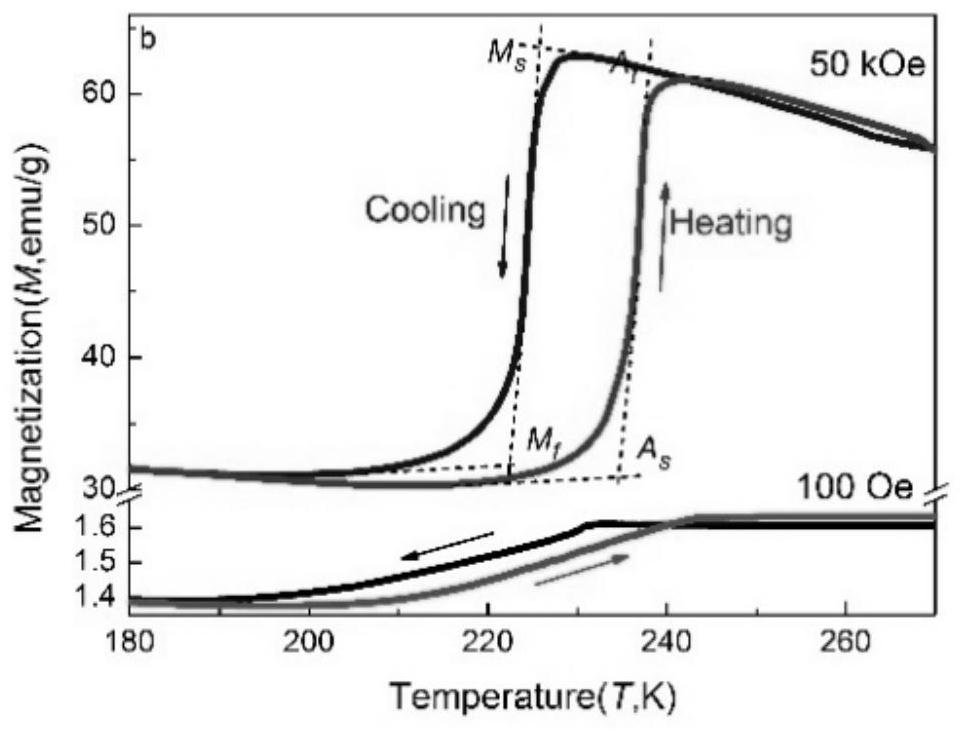

[0025] Ni-Co-Mn-Sb magnetic refrigeration alloy, the sum of moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Co:Mn:Sb=46:4:38:12. Its preparation method is as follows:

[0026] S1, according to the chemical formula Ni 46 co 4 mn 38 Sb 12 Weigh the metal element and ingredients.

[0027] S2. Put the raw materials prepared in S1 into the electric arc furnace, and evacuate to ≤3×10 -3 Pa, after cleaning once with high-purity argon (purity 99.996wt%), under the protection of 0.5 atmospheres of high-purity argon (purity 99.996wt%), the arc is started, and the melting is repeated 4 times, and the melting current is 120A. After the smelting is finished, it is cooled in a copper crucible to obtain a cast alloy ingot.

[0028] S3. Vacuum-seal the alloy ingot obtained in step S2, heat it at 900°C for 24 hours, at 720°C for 2 hours, at 700°C for 5 hours, and at 500°C for 20 hours, and finally cool it to room temperature with the furnace to break...

Embodiment 2

[0039] Ni-Co-Mn-Sb-Al magnetic refrigeration alloy, the sum of moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Co:Mn:Sb:Al=46:4:38:11.75:0.25. Its specific preparation process is as follows:

[0040] S1, according to the chemical formula Ni 46 co 4 mn 38 Sb 11.75 al 0.25 Weigh the metal element and ingredients.

[0041] S2. Put the raw materials prepared in S1 into the electric arc furnace respectively, and evacuate to ≤3×10 -3 Pa, after cleaning once with high-purity argon (purity 99.996wt%), under the protection of 0.5 atmospheres of high-purity argon (purity 99.996wt%), the arc was started, and the melting was repeated 4 times, and the melting current was 120A. After the smelting is finished, it is cooled in a copper crucible to obtain a cast alloy ingot.

[0042] S3. Vacuum-seal the alloy ingot obtained in S2, keep it at 900°C for 24 hours, at 720°C for 2 hours, at 700°C for 5 hours, at 500°C for 20 hours, and finally cool to ro...

Embodiment 3

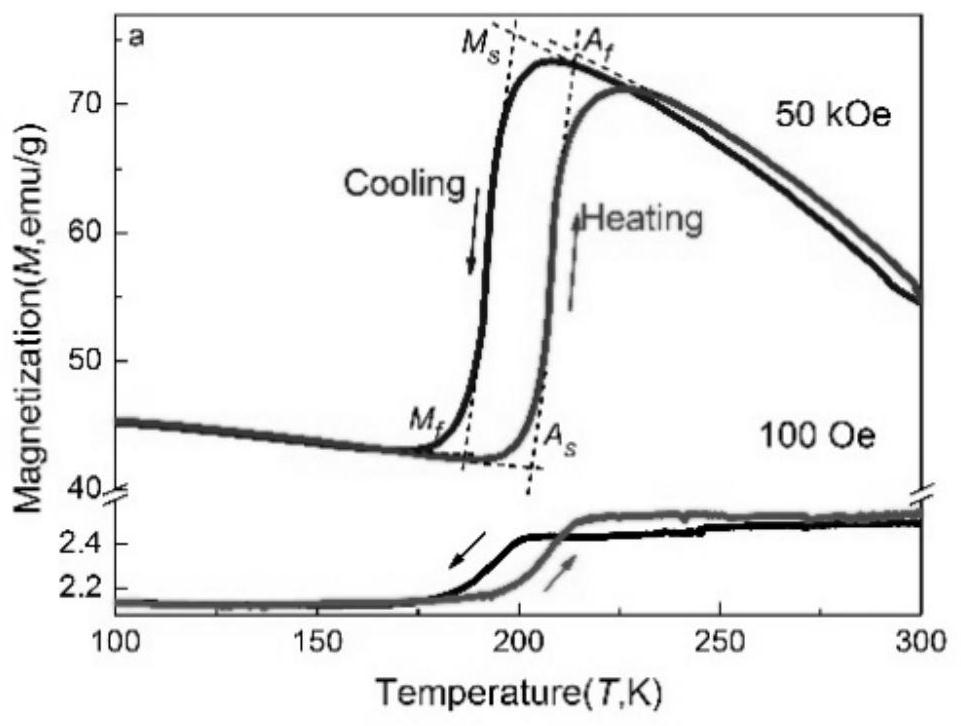

[0046] Ni-Co-Mn-Sb-Al magnetic refrigeration alloy, the sum of moles of elements in the alloy material is 100, and the molar ratio of elements is Ni:Co:Mn:Sb:Al=46:4:38:11.5:0.5. Its specific preparation process is as follows:

[0047] S1, according to the chemical formula Ni 46 co 4 mn 38 Sb 11.5 al 0.5 Weigh the metal element and ingredients.

[0048] S2. Put the raw materials prepared in S1 into the electric arc furnace respectively, and evacuate to 3×10 -3 Below Pa, after cleaning once with high-purity argon (purity 99.996wt%), under the protection of 0.5 atmospheres of high-purity argon (purity 99.996wt%), the arc is started, and the melting is repeated 4 times, and the melting current is 120A . After the smelting is finished, it is cooled in a copper crucible to obtain a cast alloy ingot.

[0049] S3. Vacuum-seal the alloy ingot obtained in S2, keep it at 900°C for 24 hours, at 720°C for 2 hours, at 700°C for 5 hours, at 500°C for 20 hours, and finally cool to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com