Preparation method of biomass-based porous carbon and product

A technology of porous carbon and biomass, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of small specific surface area of the product and complicated preparation process, and achieve the effect of simple method, simple process and high activation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

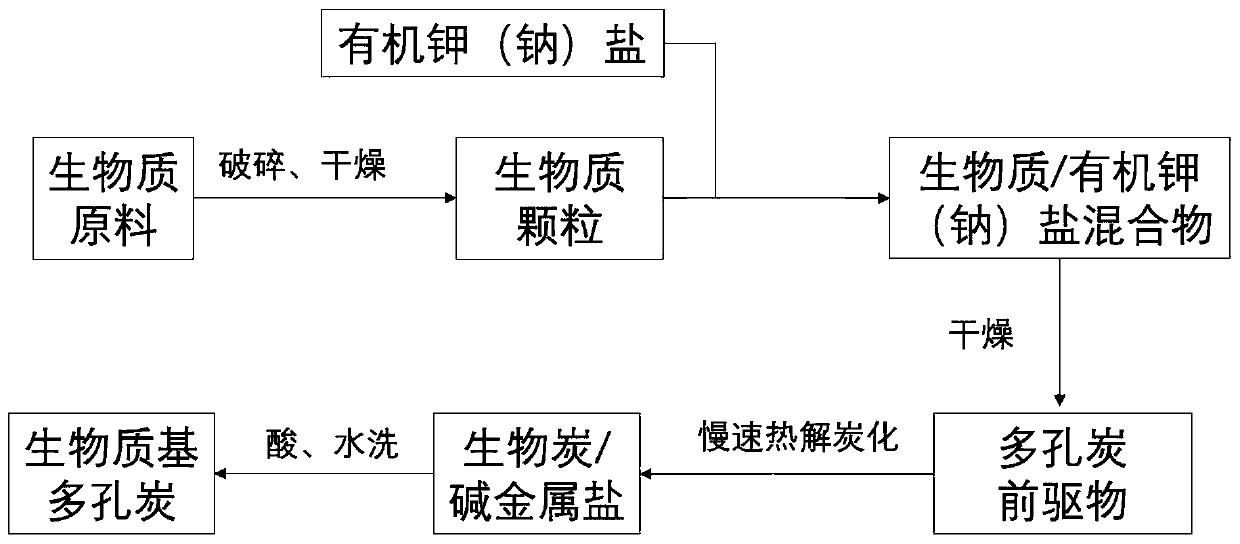

[0047] Such as figure 1 Shown is a flow chart of a preparation method for a biomass-based porous carbon constructed according to a preferred embodiment of the present invention, comprising the following steps:

[0048] S1 crushing biomass to biomass particles smaller than 40 mesh; wherein, the biomass is sugar biomass and / or lignocellulosic biomass

[0049] S2 Mix the biomass particles obtained in step S1 with organic potassium salt or organic sodium salt according to a certain mass ratio, and then dry to obtain a porous carbon precursor; wherein, the biomass particles and organic potassium salt or organic sodium salt The mass ratio is 1:0.5-1:4. Preferably, the mass ratio of the biomass particles to organic potassium salt or organic sodium salt is 1:1-1:2. The material particles are mixed with organic potassium salt or organic sodium salt by direct mechanical mixing or solvent-assisted mechanical mixing. In the solvent-assisted mechanical mixing method, a mixed solvent need...

Embodiment 1

[0056] Example 1, the raw material is cellulose, the main component of lignocellulosic biomass. ,

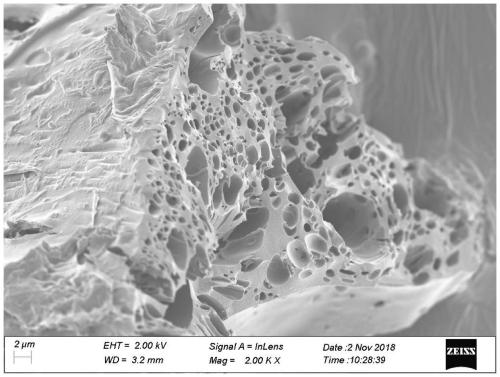

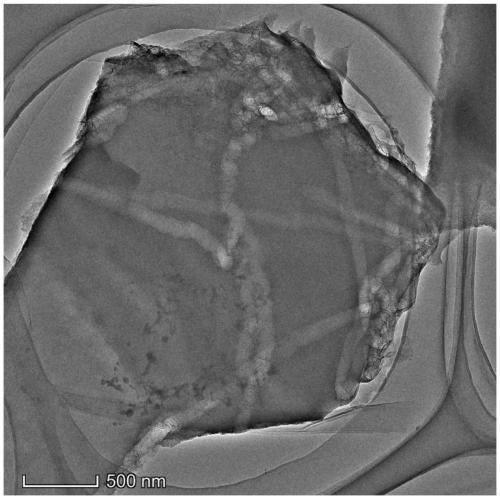

[0057] Weigh 0.5g of microcrystalline cellulose and 0.5g of potassium acetate, add 0.5mL of absolute ethanol and mix to a thick slurry, transfer to a corundum crucible, carry out one-step drying and one-step inert atmosphere calcination in a vertical furnace, the heating program is : From room temperature to 100°C in 5 minutes, after keeping for 30 minutes, raise the temperature to 800°C at a rate of 10°C / min and keep it warm for 2 hours. After natural cooling, a semi-finished product of biochar is obtained. The obtained biochar was washed with 1M hydrochloric acid for 6 hours, washed with deionized water until neutral, and dried at 80° C. for 10 hours to obtain a biomass-based porous carbon with an actual yield of about 14.1% (based on the quality of raw materials). Its scanning electron microscope picture is as figure 2 As shown, micron-scale etched channels can be seen dee...

Embodiment 2

[0058] In Example 2, the raw material is xylan, the main sugar component in lignocellulosic biomass.

[0059] Weigh 0.5g of xylan extracted from beech wood and 0.5g of potassium acetate, add 0.2mL of absolute ethanol to mix to a thick slurry, transfer to a corundum crucible, and perform one-step drying and one-step inert atmosphere in a vertical furnace For calcination, the heating program is as follows: rise from room temperature to 700°C for 5 minutes, hold for 30 minutes, then raise the temperature to 800°C at a rate of 10°C / min and hold for 2 hours. After natural cooling, the biochar semi-finished product is obtained. The obtained biochar was washed with 1M hydrochloric acid for 6 hours, washed with deionized water until neutral, and dried at 100°C for 2 hours to obtain a biomass-based porous carbon with an actual yield of about 4% (based on the quality of raw materials). Its scanning electron microscope picture is as Figure 5 As shown, it can be seen that the macroporou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com