Gel electrolyte and lithium-sulfur secondary battery

A technology of gel electrolyte and liquid electrolyte, which is applied in the field of electrochemistry, can solve the problems that lithium-sulfur secondary batteries need to be improved, and achieve the effects of improving charge and discharge efficiency, good electrochemical performance and safety, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

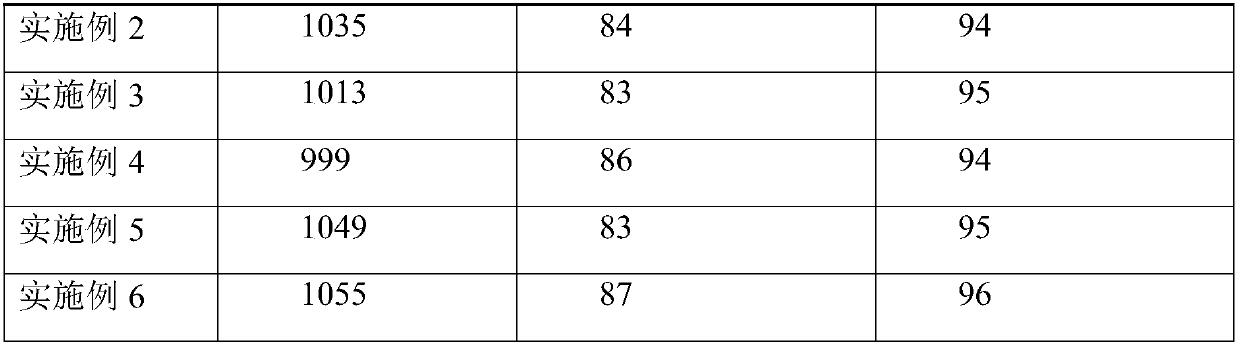

Examples

Embodiment 1

[0054] After preparing liquid electrolyte E1, add 1% of 2-[[2,2-bis[[(1-oxo-2-propenyl]methyl]butoxy]methyl]-2-ethyl- 1,3-propanediyl-2-acrylate (CAS No.: 94108-97-1) and 0.05% peroxybenzoic acid initiator to obtain gel electrolyte ES1;

[0055] Liquid injection and cell molding: inject the above-mentioned gel electrolyte ES1 into the baked cell (the preparation of the cell is the same as in Comparative Example 1), and let it stand until the electrolyte soaks the entire diaphragm. After standing at a high temperature of 80°C for 4 hours, then Processes such as chemical formation, shaping, and degassing were carried out to finally obtain the lithium-sulfur battery example BS1.

Embodiment 2

[0057] After preparing liquid electrolyte E2, add 1% of 2-[[2,2-bis[[(1-oxo-2-propenyl]methyl]butoxy]methyl]-2-ethyl- 1,3-propanediyl-2-acrylate (CAS No.: 94108-97-1) and 0.05% peroxybenzoic acid initiator to obtain gel electrolyte ES2;

[0058] Liquid injection and cell molding: inject the above-mentioned electrolyte ES2 into the baked cell (the preparation of the cell is the same as in Comparative Example 1), let it stand until the electrolyte soaks the entire diaphragm, and leave it at a high temperature of 65°C for 6 hours before performing the formation , shaping, degassing and other processes to finally obtain the lithium-sulfur battery embodiment BS2.

Embodiment 3

[0060] After preparing liquid electrolyte E1, add 2% of 2-[[2,2-bis[[(1-oxo-2-propenyl]methyl]butoxy]methyl]-2-ethyl- 1,3-propanediyl-2-acrylate (CAS No.: 94108-97-1) and 0.08% AIBN to obtain gel electrolyte ES3;

[0061] Liquid injection and cell molding: inject the above-mentioned electrolyte ES3 into the baked cell (the preparation of the cell is the same as that of Comparative Example 1), let it stand until the electrolyte soaks the entire diaphragm, and leave it at a high temperature of 80°C for 4 hours before performing the formation , shaping, degassing and other processes to finally obtain the lithium-sulfur battery embodiment BS3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com