Infrared detector chip for increasing capacitance density

An infrared detector and capacitance density technology, applied in the field of infrared detectors, can solve the problems of reduced capacitance area, poor matching of readout circuits, and small capacitance density, so as to increase capacitance density, improve performance matching, and capacitance density. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

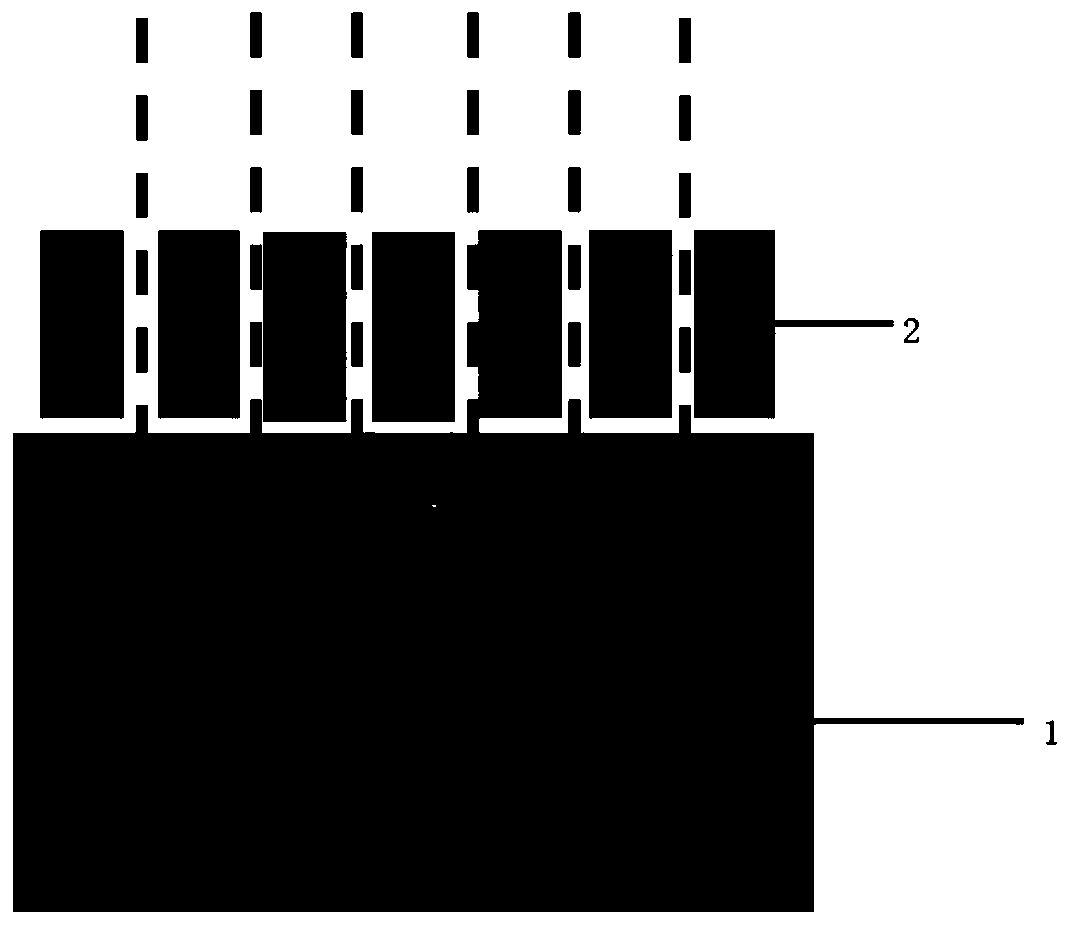

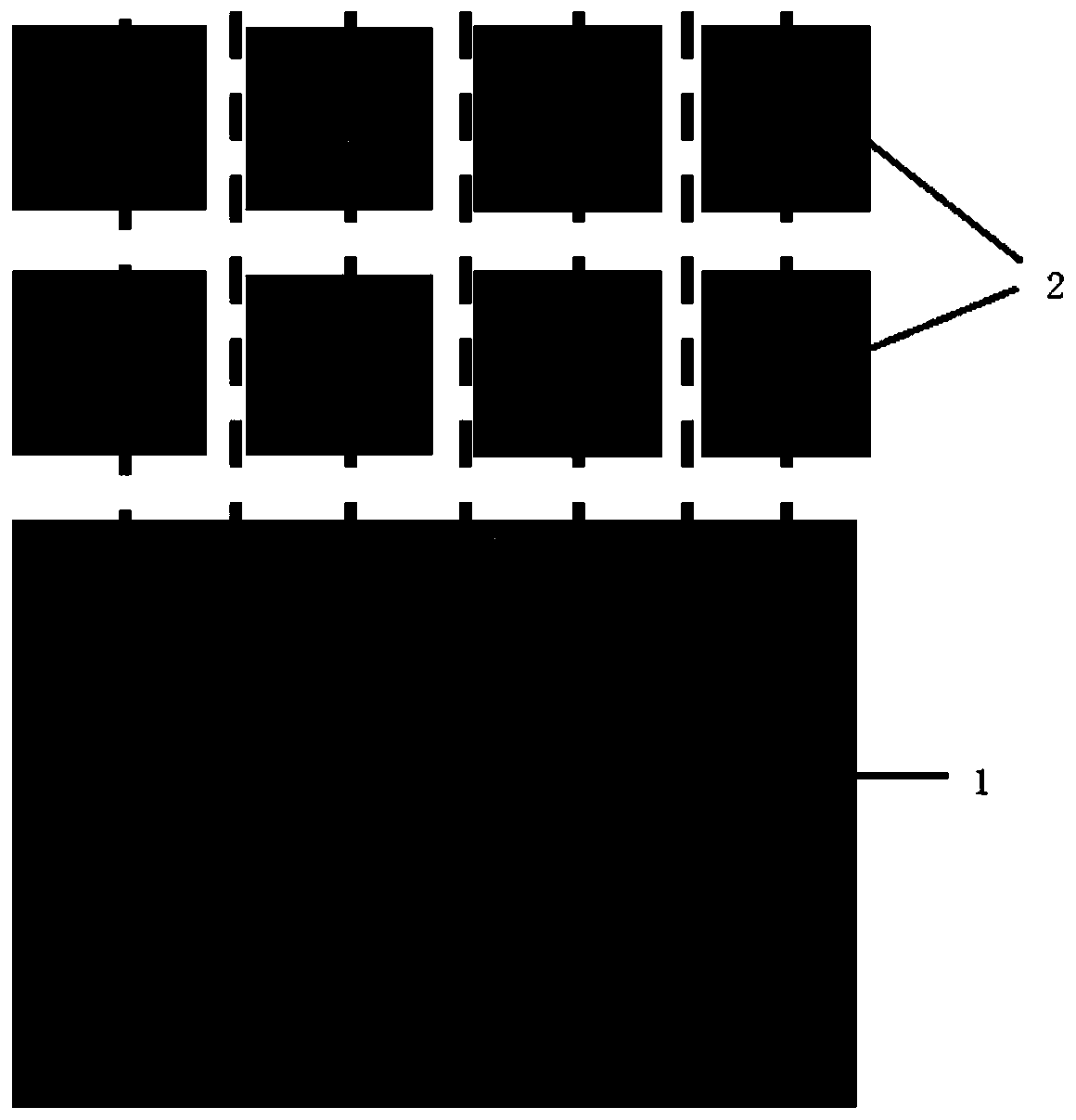

[0029] as attached figure 2 As shown, the purpose of the infrared detector chip provided by the present invention is to increase the area of the capacitor unit, thereby improving the matching between the capacitor units corresponding to different columns and the readout circuits. In this embodiment, the infrared detector chip includes a pixel array 1 and a capacitor array required by the readout circuit. The pixel array 1 includes pixel units of M rows and N columns, and the capacitor array includes capacitor units 2 of 2 rows and N / 2 columns. , wherein the width of the capacitor unit is the sum of the widths of the two pixel units, and the sum of the widths of the two pixel units includes the sum of the two pixel units and their gaps; and the capacitor array is located on the upper side of the detector chip, in the vertical In the direction, the two capacitor units are arranged in parallel and keep the same width as the two pixel units below them. The uppermost side of th...

Embodiment 2

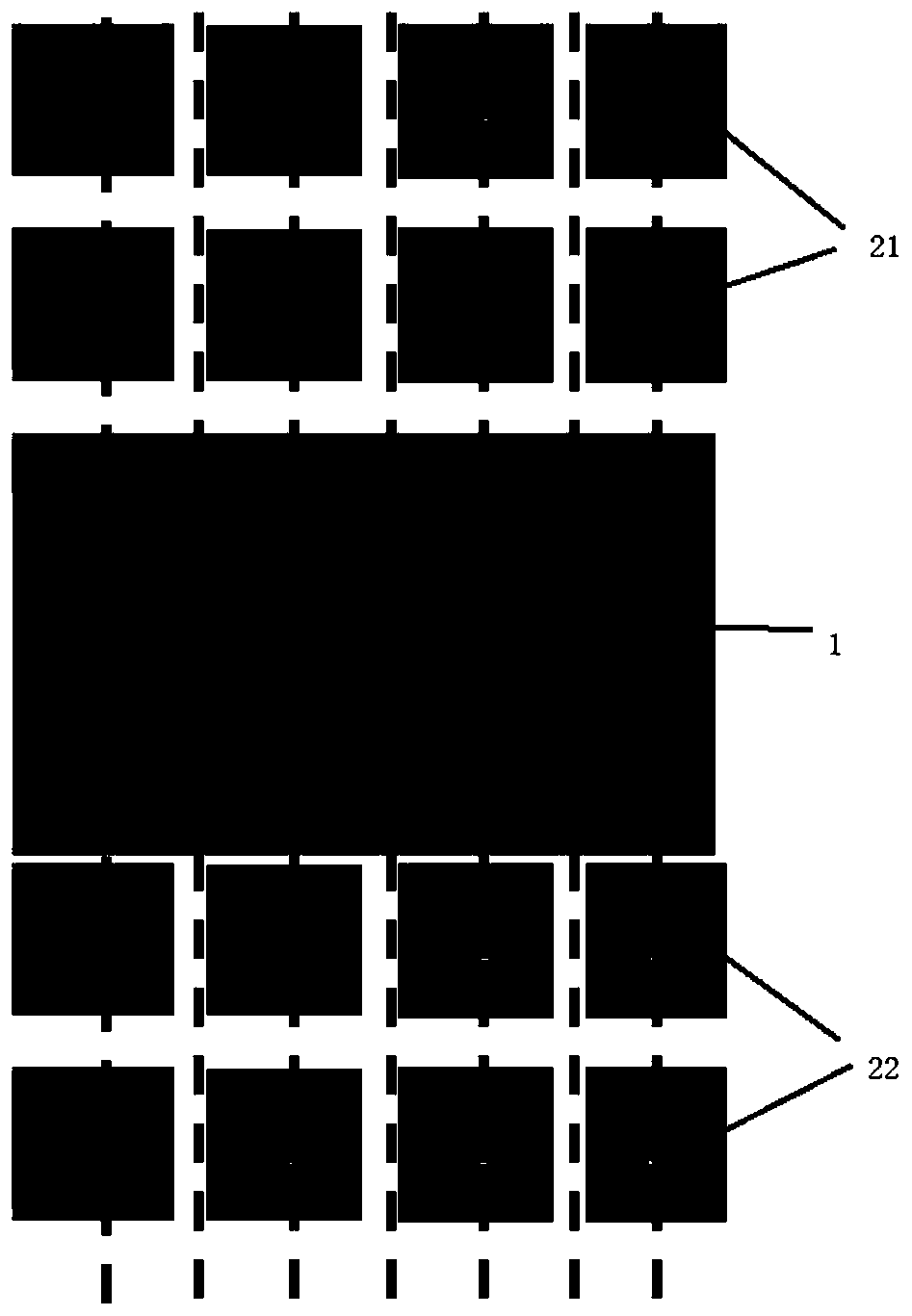

[0033] With the increase of pixel units in the pixel array, if the readout circuit is still distributed on one side of the pixel array, during the signal transmission process of the pixel units in each column, the pixel unit far away from the readout circuit reaches the gap between the capacitor units The parasitic effect is much different from the parasitic effect between the pixel unit close to the readout circuit and the capacitor unit, and as the size of a single pixel unit becomes smaller, it becomes more and more difficult to reduce the parasitic effect by increasing the line width. Therefore, the present invention The capacitor unit of each row of pixel units is split into the upper and lower sides of the pixel array, and the matching between the pixel unit and the capacitor unit is ensured as much as possible.

[0034] The capacitor unit in the present invention includes an upper capacitor array and a lower capacitor array, the upper capacitor array is located above the...

Embodiment 3

[0043] The areas of the metal layer and the through-hole layer in the adjacent metal sub-module and the through-hole sub-module are different on the horizontal section. One correspondence, also may not correspond.

[0044] Please refer to the attached Figure 5 , when the horizontal cross-sectional area of the metal layer 51 is larger than the horizontal cross-sectional area of the via layer 52, the horizontal capacitor 7 can be formed through the dislocation connection of the via layer to the metal layer. Horizontal capacitance can exist between two adjacent metal sub-modules, and can exist between the bottom metal sub-module and the polysilicon module, as shown in the attached Figure 5 shown. Among them, in order to form a horizontal capacitor between metal layers, the following three requirements need to be met: first, the metal layers in adjacent metal sub-modules are opposite in the vertical direction; second, the two opposite metal layers If they are not connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com