A frp strip reinforced thermoplastic resin spiral corrugated pipe

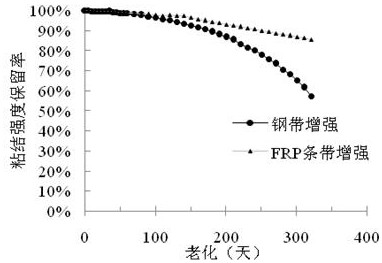

A technology that enhances thermoplasticity and thermoplastic resins. It is applied in the direction of rigid pipes, pipes, and pipeline protection. It can solve problems such as large deformation, short service life, and buckling instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the principles and features of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

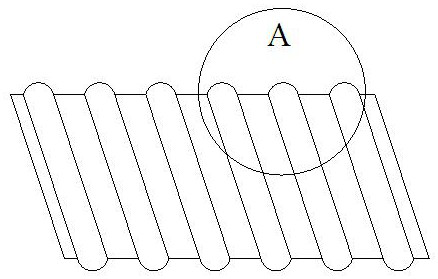

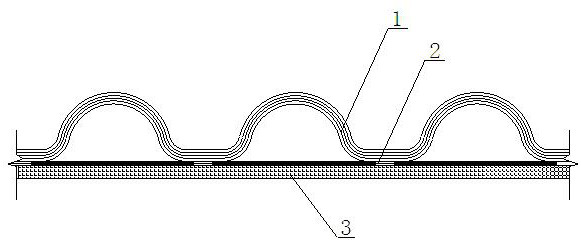

[0022] Such as Figure 1-2 As shown, the FRP reinforced thermoplastic resin spiral corrugated pipe of the present invention includes an outer layer 1 , an intermediate layer 2 and an inner layer 3 . The middle 2 is helically wound on the outer surface of the inner layer 3 . According to the flow design, the nominal diameter of the pipe is 800mm, the inner diameter is 785mm, the inner layer wall thickness is 4mm, the middle layer fiber reinforced FRP strip thickness is 0.5mm, the outer layer wall thickness is 3mm, the laminated wall thickness is 7.5mm, the spiral rib spacing is 100mm, the FRP strip The belt spacing is 100mm.

[0023] The inner layer 3 is made of ordinary thermoplastic resin, polyethylene resin, with a strength of 18MPa, an elastic modulus of 800MPa, and an impact st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com