Asphalt concrete interlayer bonding material and preparation method and application method thereof

A technology of asphalt concrete and bonding material, applied in the direction of coagulation pavement, adhesive type, ester copolymer adhesive, etc. for on-site paving, which can solve the problem of reducing road use effect and service life, bonding strength and resistance. Insufficient shear strength, easy to cause shifting, delamination and other problems, to achieve the effect of improving convenience, improving interlayer bonding strength and shear strength, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

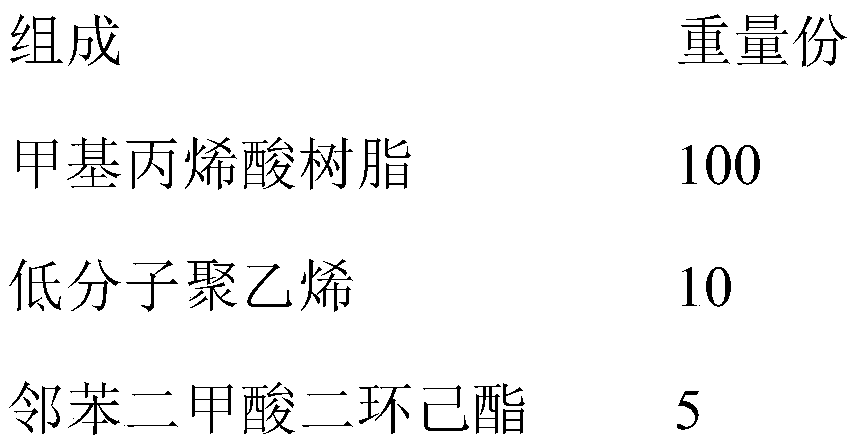

Embodiment 1

[0016]

[0017] The components were mixed uniformly according to the proportion and then blow molded to form hollow pellets with a diameter of 3 mm and a wall thickness of 0.6 mm.

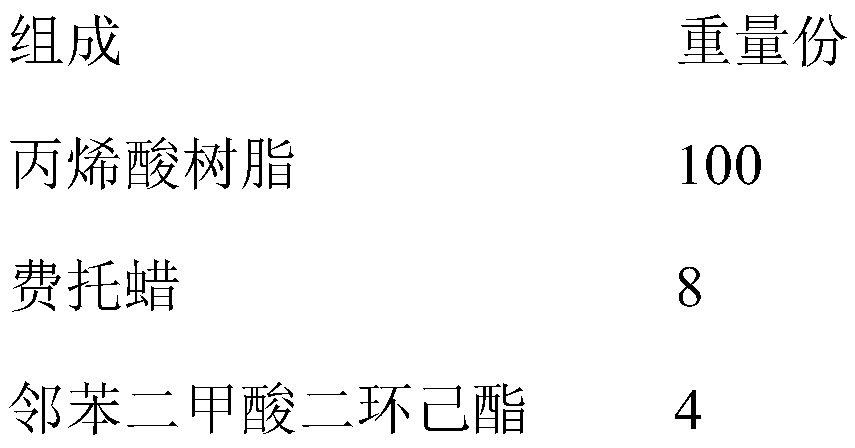

Embodiment 2

[0019]

[0020] The components were mixed uniformly according to the proportion, and then blow molded to form hollow pellets with a diameter of 2 mm and a wall thickness of 0.5 mm.

Embodiment 3

[0022]

[0023]

[0024] The components were mixed uniformly according to the proportion, and then blow-molded to form hollow pellets with a diameter of 1 mm and a wall thickness of 0.3 mm.

[0025] On steel plate and cement concrete base surface, brush 0.6~1.0Kg / m 2 epoxy resin, sprinkle the asphalt concrete interlayer bonding material prepared in Examples 1 to 3, clean up the unadhered excess material after the epoxy resin is cured, and then add different types of asphalt concrete, the interlayer bonding The strength and shear strength are shown in the table below:

[0026]

[0027] The advantage of the present invention is that the interlayer adhesive material used has a suitable melting point, and it is prepared into hollow pellets by blow molding, which can be completely melted and embedded into the interior of the asphalt mixture during the paving and rolling process of the asphalt mixture , improve the interlayer bonding strength and shear strength between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com