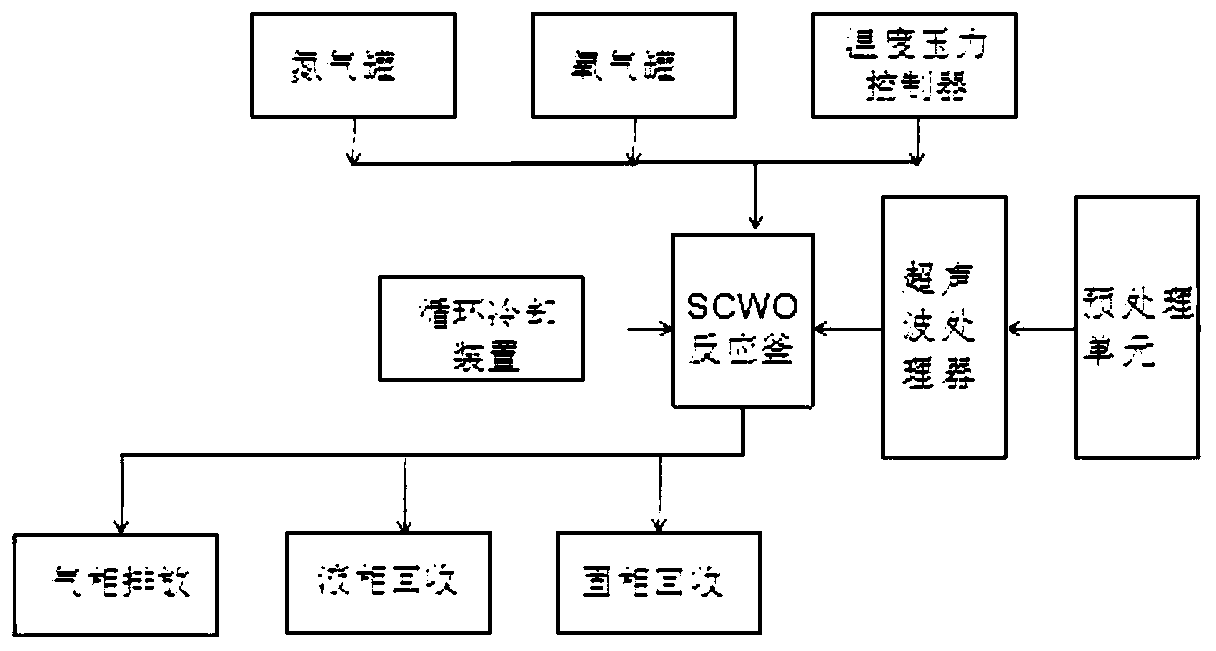

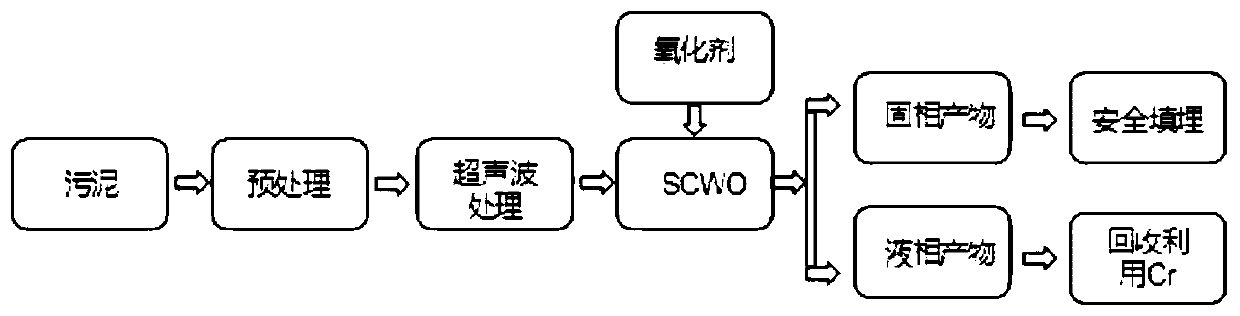

Chromium-containing sludge treatment method and system based on supercritical water oxidation reaction

A supercritical water oxidation and sludge treatment technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., to reduce leaching toxicity, simple process, and large resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for treating chromium-containing sludge, comprising the following steps:

[0050] 1) Pretreatment: Before the experiment, the sludge was dried in a high-temperature oven at 105°C for 24 hours to ensure that the water was completely lost. Then use a planetary ball mill to grind the solid sludge into powder, use a vibrating sieve to divide the sludge into different particle sizes, and use the sludge powder under a 300-mesh sieve as the original sludge.

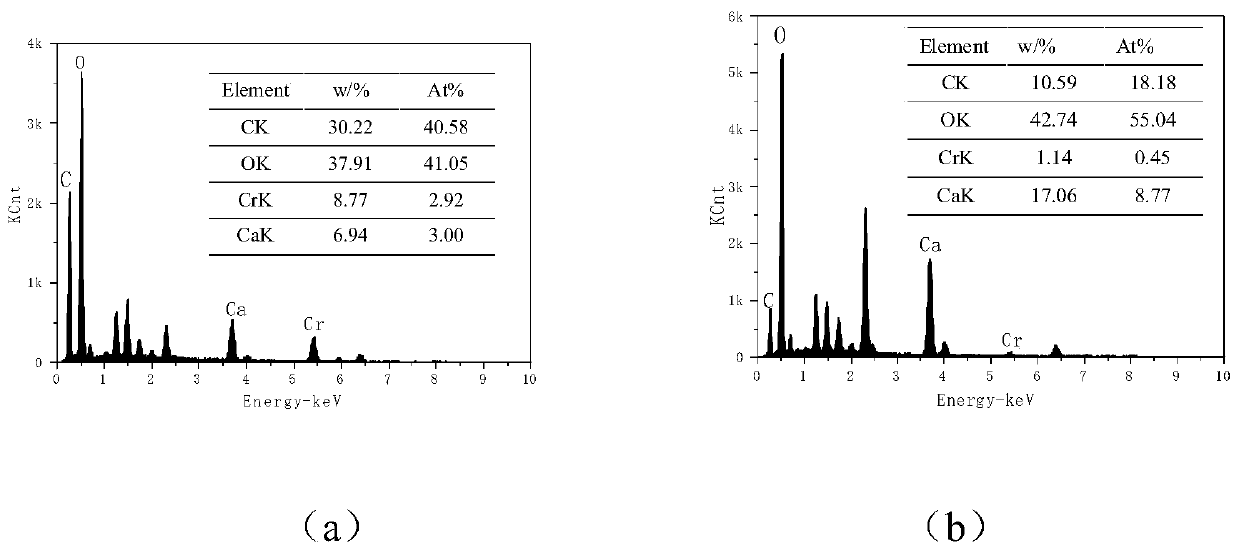

[0051] Take 1g of raw sludge and weigh it, put it into a muffle furnace and burn it at 600°C until it reaches a constant weight, then weigh it and subtract it from the initial value to get the organic matter content, which is 49.9%.

[0052] Take 0.1000g of raw sludge, add 2mL of ultrapure water to wet it in a polytetrafluoroethylene crucible, and then add 5mL of 98% HNO 3 and 2mL HF, heated on a hot plate (temperature 150-200°C) until nearly dry, then removed and cooled to room temperature. Add 5mL HF and cont...

Embodiment 2

[0058] Compared with Example 1, the difference is that the temperature of the supercritical water oxidation reaction is adjusted to 470°C.

[0059] Test Results:

[0060] The removal rate of TOC in sludge can reach 98.9%, the lowest is 16.92mg / L. The supernatant Cr is 1074.8mg / L, and 67.2% of the Cr in the sludge will be transferred to the liquid phase, and the sludge cannot meet the national discharge requirements.

Embodiment 3

[0062] Compared with Example 1, the difference is that the temperature of the supercritical water oxidation reaction is adjusted to 520°C.

[0063] Test Results:

[0064] At 520°C, the supernatant TOC is 15.7mg / L, and the removal rate can still reach 99%. The supernatant Cr reaches 1219.1mg / L, and the Cr mobility is 73.0%. The sludge does not meet the national discharge requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com