Boiler maintenance platform

An inspection platform and inspection platform technology, applied in the direction of lifting equipment safety devices, lifting devices, etc., can solve the problems of time-consuming, laborious and dangerous, damaged protective layer, multiple detection dead angles, etc., to achieve rapid installation and construction, promote quality improvement, The effect of less maintenance dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

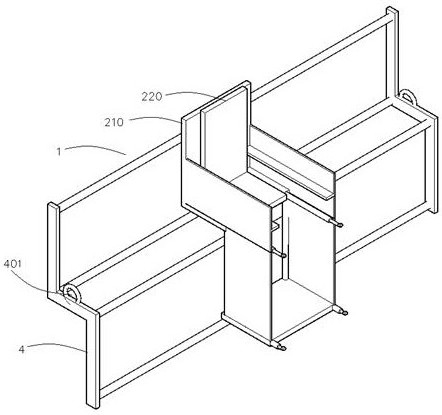

[0045] Such as Figure 1-6 As shown, a boiler maintenance platform is hoisted and lifted by a sling, including an assembled guide rod 1 and a sitting maintenance platform 2;

[0046] The sitting maintenance platform 2 includes a sitting maintenance chair 210 and a safety seat cushion 220. The sitting maintenance chair 210 includes a seat back 211, a seat surface 212, and a foot support surface 214 from top to bottom. The seat surface 212 Set horizontally with the foot support surface 214, the rear portion of the foot support surface 214 and the front portion of the chair surface 212 are fixed by the vertical connecting rod 213; Personnel can stand on the foot support for short periods of time for maintenance operations.

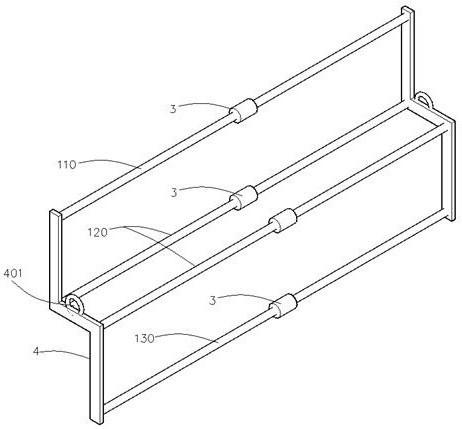

[0047] The guide rod 1 is arranged horizontally, including a first guide rod 110 arranged at the rear of the chair back 211, a second guide rod 120 arranged at the bottom of the chair surface 212, and a second guide rod 120 arranged at the bottom of the foot...

Embodiment 2

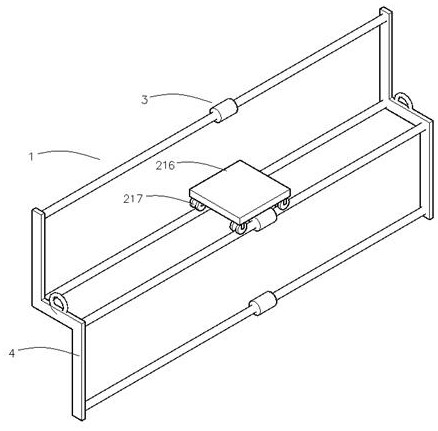

[0064] Such as Figure 7 As shown, similar to Embodiment 1, the difference is that an orientation wheel 402 is provided in front of the guide rod frame, and a magnetic bar is provided on the surface of the wheel body of the guide rod frame 402, and the orientation wheel 402 and the rod guide frame 4 pass through the first Three telescopic rods 403 are connected and fixed;

[0065] The directional wheel 402 can only roll upwards or downwards, and it can be adsorbed on the boiler wall by magnetic force. When the sitting maintenance platform moves horizontally, it can offset the reaction force generated on the guide rod and increase the stability.

Embodiment 3

[0067] When it is necessary to temporarily stand up for maintenance operations, the safety belt on the safety seat cushion cannot be untied, and safety can be ensured by increasing the extension of the safety belt and adding safety belts to the feet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com