Multi-lens grinding vessel jig

A lens and jig technology, applied in the direction of grinding machines, manufacturing tools, optical surface grinders, etc., can solve the problems of product shape and size errors, low production efficiency, high yield, etc., to reduce intervention, shorten process time, and improve production efficiency and the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

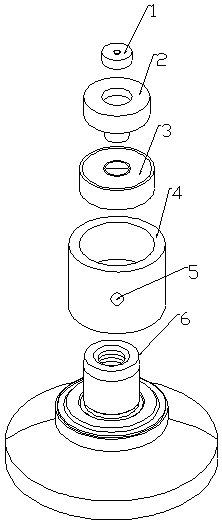

[0014] Depend on figure 1 As shown, the multi-piece abrasive dish fixture for the lens, the honeycomb dish 6 of the working part is installed on the white plastic steel nut 4, and the white plastic steel nut has a nut hole 5, which is convenient for the honeycomb dish 6 to take. The extension of the 608 bearing 3 is installed on the The upper end of the white plastic steel nut 4 and the 608 bearing 3 are internally installed on the protruding part of the copper utensil 2, and the nickel alloy terminal 1 is installed on the copper utensil 2. The nickel alloy terminal 1 is installed on the working rod of the machine table. After the machine is turned on, the working shaft drives the honeycomb dish of the working part to rotate, and the upper part is pressed on the nickel alloy terminal by the tip of the string rod, so that the entire bearing screw cap will rotate rapidly following the operation of the working shaft, so that there will be no honeycomb The 6 rotations of the dish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com