Nitrogen-doped layered nano carbon catalyst as well as preparation and application thereof

A layered nano-carbon catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as secondary pollution, and achieve low cost, convenient operation, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Disperse 1g of β-cyclodextrin and 1g of melamine in 80mL of water and 40mL of methanol, and disperse them by ultrasonication for 30min;

[0052] (2) Stir the mixed solution dispersed in step (1) on a magnetic stirrer at 80° C. at a speed of 300 r / min overnight;

[0053] (3) Put the solid mixture that was stirred and evaporated in step (2) in a quartz boat and put it into a tube furnace; roast it under the condition that the inert atmosphere is argon, and the roasting program is: with a speed of 5° C. / min Heated to 600°C and kept at 600°C for 4h, then the sample was heated to 800°C at 2°C / min and kept for 3h to obtain a nitrogen-doped layered nanocarbon material named N1C-800, Ar.

Embodiment 2

[0055] (1) Disperse 1g of β-cyclodextrin and 1g of melamine in 80mL of water and 40mL of methanol, and disperse them by ultrasonication for 30min;

[0056] (2) Stir the mixed solution dispersed in step (1) on a magnetic stirrer at 80° C. at a speed of 300 r / min overnight;

[0057] (3) Put the solid mixture that was stirred and evaporated in step (2) in a quartz boat and put it into a tube furnace; roast it under the condition that the inert atmosphere is argon, and the roasting program is: with a speed of 5° C. / min Heated to 600°C and kept at 600°C for 4h, then the sample was heated to 1100°C at 2°C / min and kept for 3h to obtain a nitrogen-doped layered carbon nanomaterial named N1C-1100, Ar.

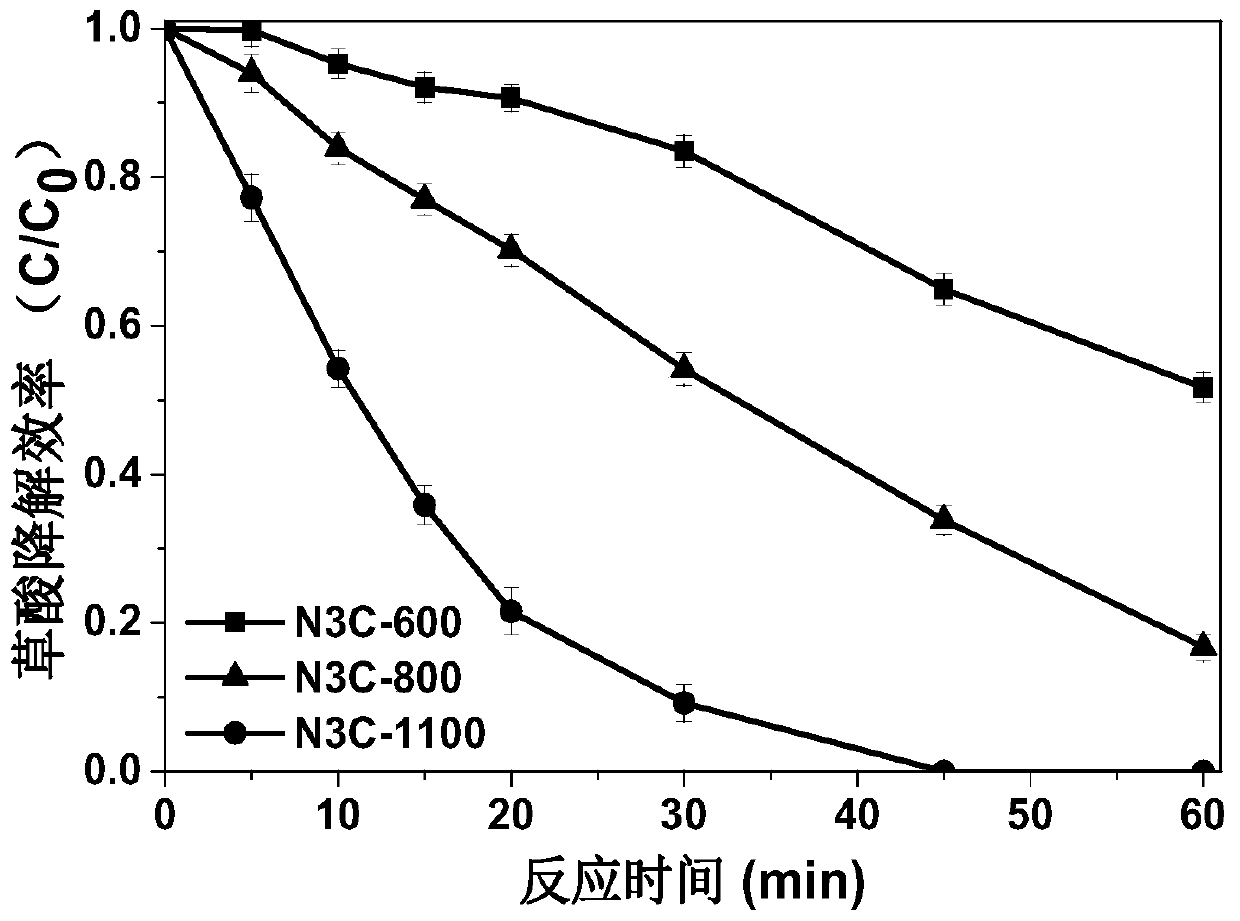

Embodiment 3

[0059] (1) Disperse 1g of β-cyclodextrin and 3g of melamine in 80mL of water and 40mL of methanol, and disperse them by ultrasonication for 30min;

[0060] (2) Stir the mixed solution dispersed in step (1) on a magnetic stirrer at 80° C. at a speed of 300 r / min overnight;

[0061] (3) Put the solid mixture that was stirred and evaporated in step (2) in a quartz boat and put it into a tube furnace; roast it under the condition that the inert atmosphere is argon, and the roasting program is: with a speed of 5° C. / min Heated to 600°C and kept at 600°C for 4h, then the sample was heated to 800°C at 2°C / min and kept for 3h to obtain a nitrogen-doped layered nanocarbon material named N3C-800, Ar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com