Battery safety heat management device

A battery safety and safety device technology, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of car battery safety that cannot be underestimated, affect battery life, battery explosion, etc., to reduce heat accumulation and prolong use Effects of lifetime, effective heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

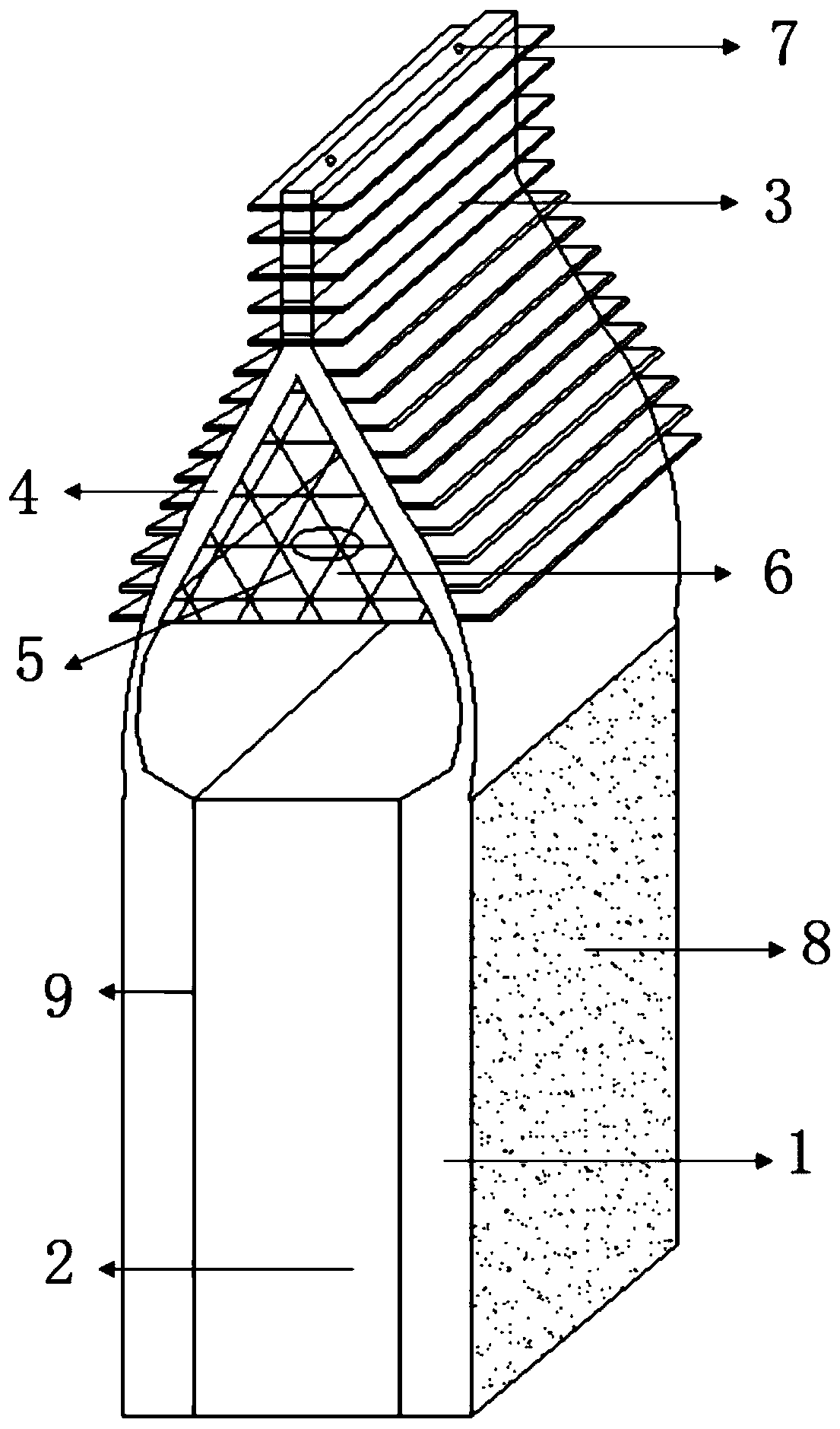

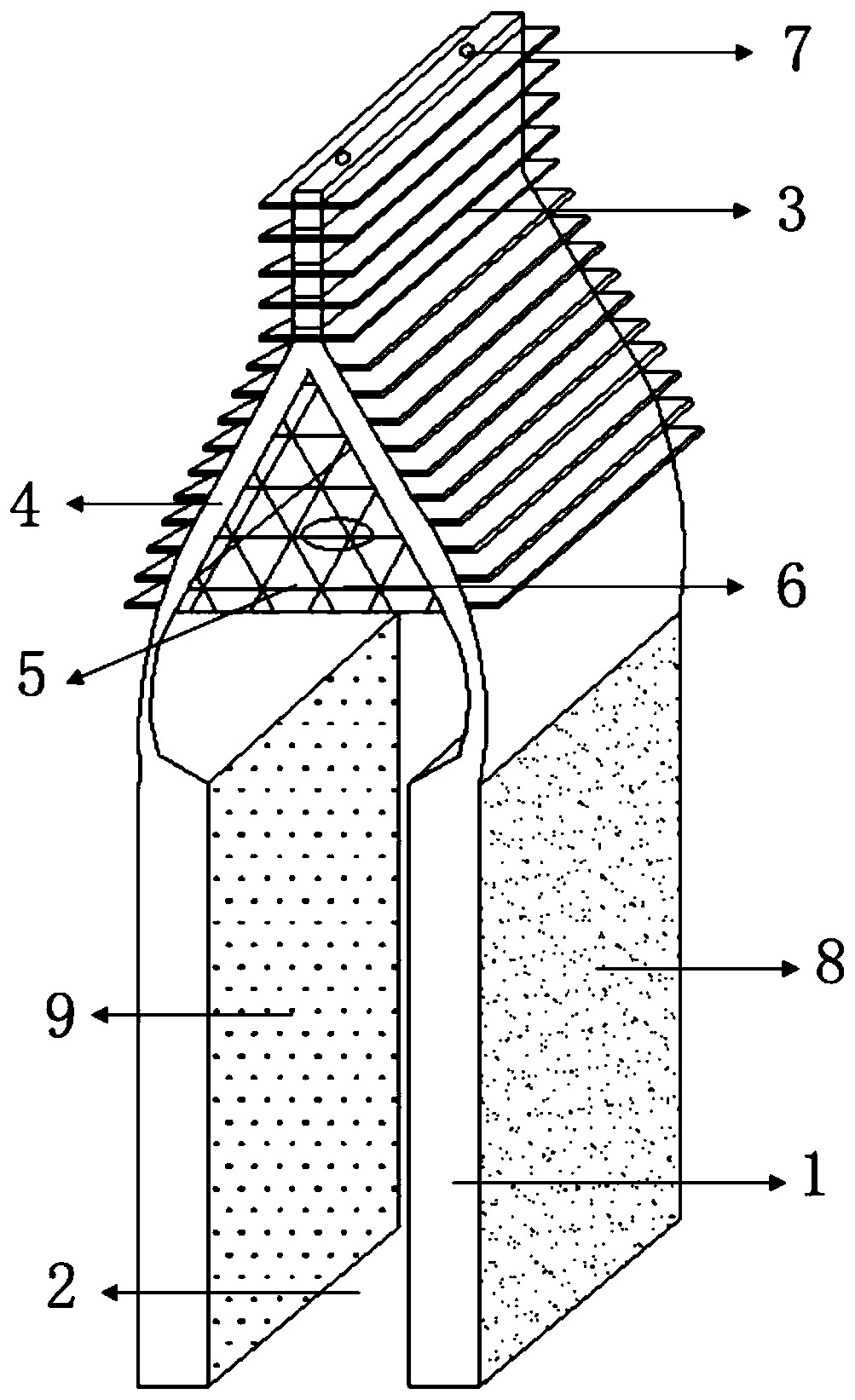

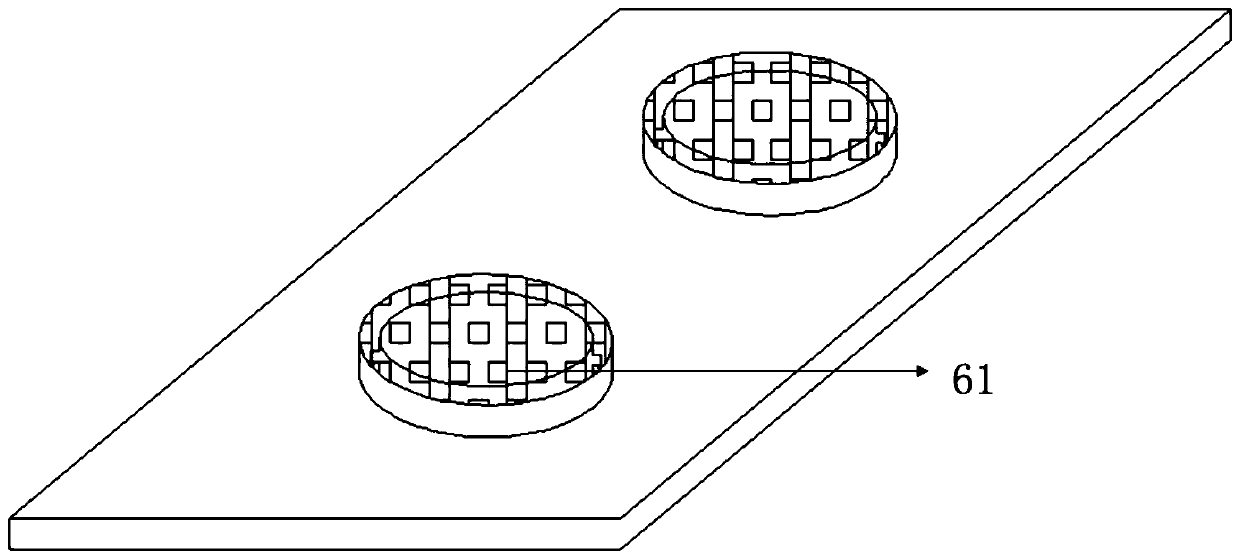

[0023] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a schematic structural view of the present invention without a battery installed, image 3 It is a schematic diagram of the bottom plate structure of the present invention, Figure 4 It is a schematic diagram of the opening structure of the present invention. As shown in the figure, the battery safety thermal management device in this embodiment includes a heat dissipation device, a recovery device and a safety device. The heat dissipation device includes a liquid storage tank 1 that conducts heat and sticks to the surface of the battery 2 , the liquid storage tank 1 is filled with a liquid phase change material with a low boiling point, and evaporates and absorbs the heat generated by the battery 2 when it is in thermal contact with the battery 2, and the phase change material that absorbs heat and evaporates into a gaseous state enters the draft tube 4; the recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com