Cooling device for centrifugal machine pouring

A technology of cooling device and centrifuge, which is applied in the field of cooling device for centrifuge pouring, can solve the problems of long operation time, low efficiency, and affecting the quality of workpiece forming, and achieve good cooling effect and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

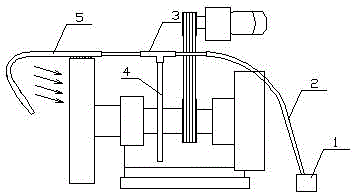

[0011] The present invention includes a water pump 1, the water pump 1 is connected to a regulating valve 3 through a water inlet pipe 2, and the regulating valve 3 is connected to a spray pipe 5 above a workpiece through a pipe.

[0012] The regulating valve 3 is fixed by a fixing bracket 4 .

[0013] The shower pipe 5 includes a front shower pipe arranged directly above the workpiece and a side shower pipe arranged on the side of the workpiece. The nozzles of the side shower pipe are arranged obliquely and are arranged on one side of the workpiece.

[0014] The water inlet pipe 2 of the present invention adopts a hose to facilitate the arrangement of the water inlet pipe 2; the nozzle of the side spray pipe of the present invention is arranged obliquely, which has an impact force on the side of the workpiece, further strengthening the cooling effect.

[0015] In the present invention, a temperature sensor can be installed near the workpiece, and a receiver can be installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com