High-efficiency motor rotor grinding equipment and using method thereof

A motor rotor, high-efficiency technology, applied to grinding/polishing equipment, grinding devices, grinding machine tools, etc., can solve the problems of cumbersome operation, high motor rotor temperature, and low grinding efficiency, so as to increase the range of air outlet and prevent overheating too high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

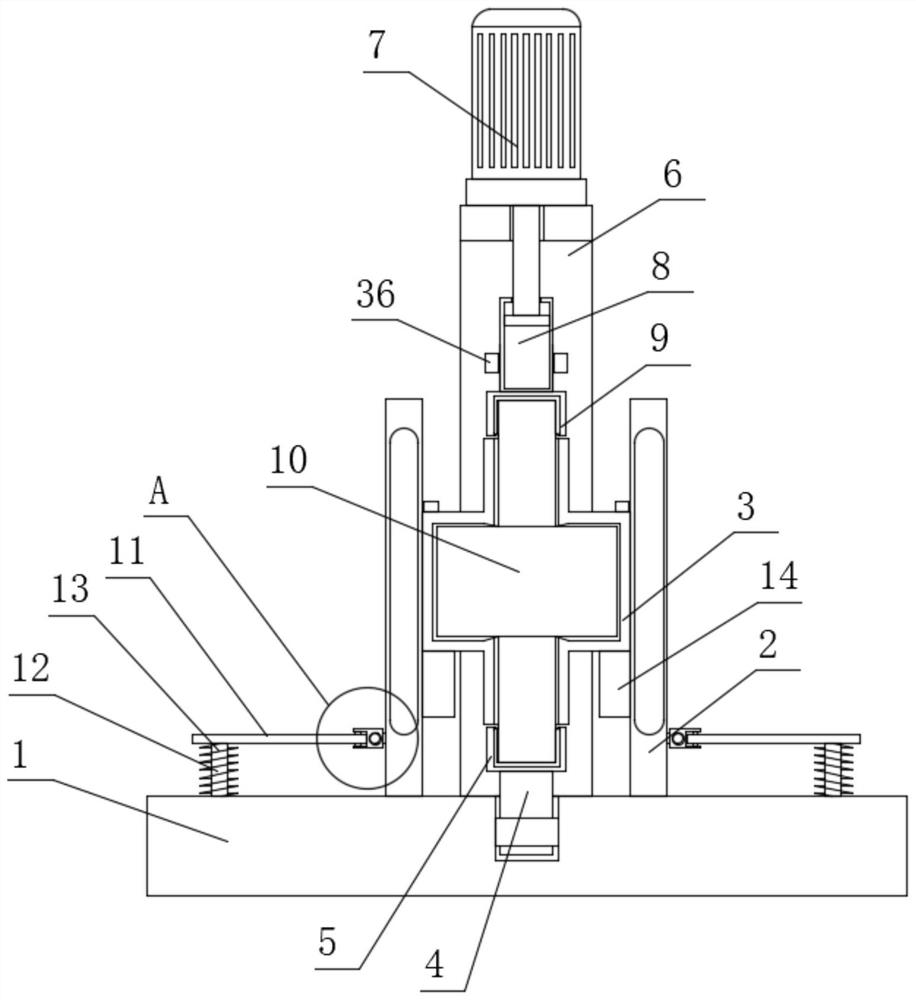

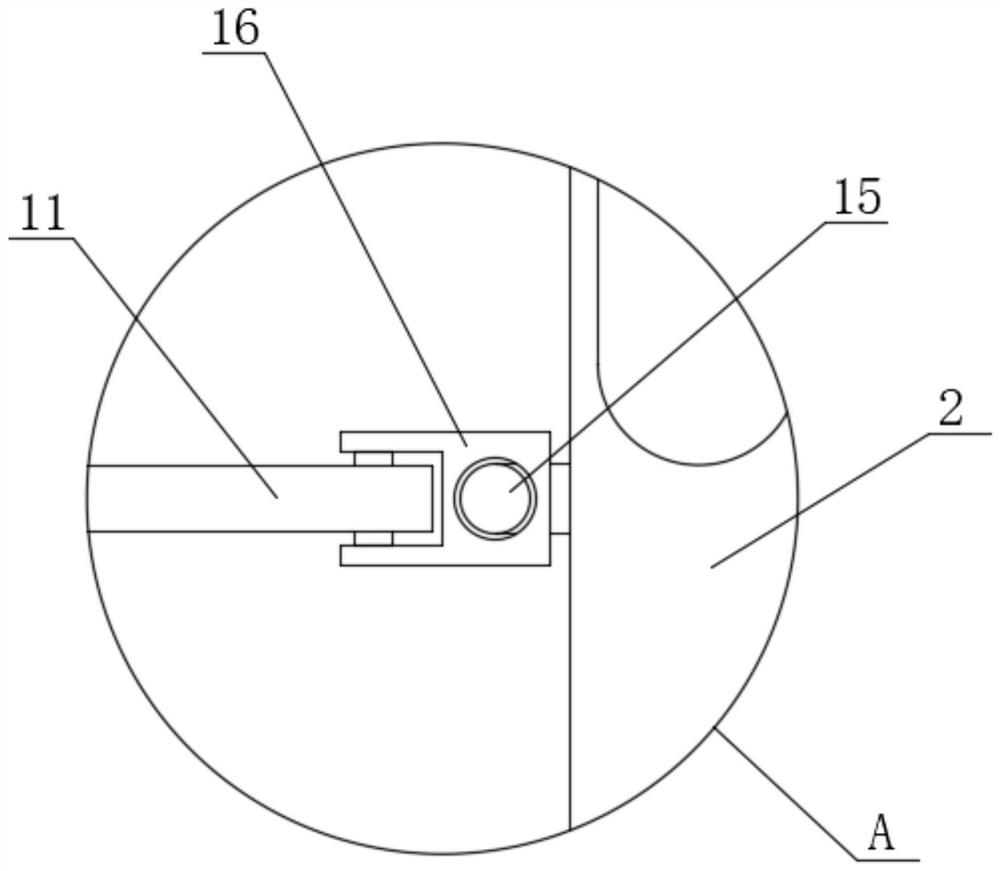

[0047] Embodiment one: if Figure 1-8 As shown, a high-efficiency motor rotor grinding equipment includes a base 1, two moving rings 2 are symmetrically slidably connected to the top of the base 1, and U-shaped grinding plates are clamped on the sides of the two moving rings 2 that are close to each other. 3. The top of the base 1 is rotatably connected with the support shaft 4 located between the two moving rings 2, the top of the support shaft 4 is fixedly installed with the support cover 5, and the motor rotor 10 is clamped inside the support cover 5, and the motor rotor 10 The top end extends to the top of the support cover 5, an L-shaped frame 6 is fixedly installed on one side of the top of the base 1, and a driving motor 7 is fixedly installed on the top of the L-shaped frame 6, and the output shaft of the driving motor 7 runs through the L-shaped frame 6 and is slidably connected There is a card cover 9, the top of the motor rotor 10 extends into the card cover 9 and i...

Embodiment 2

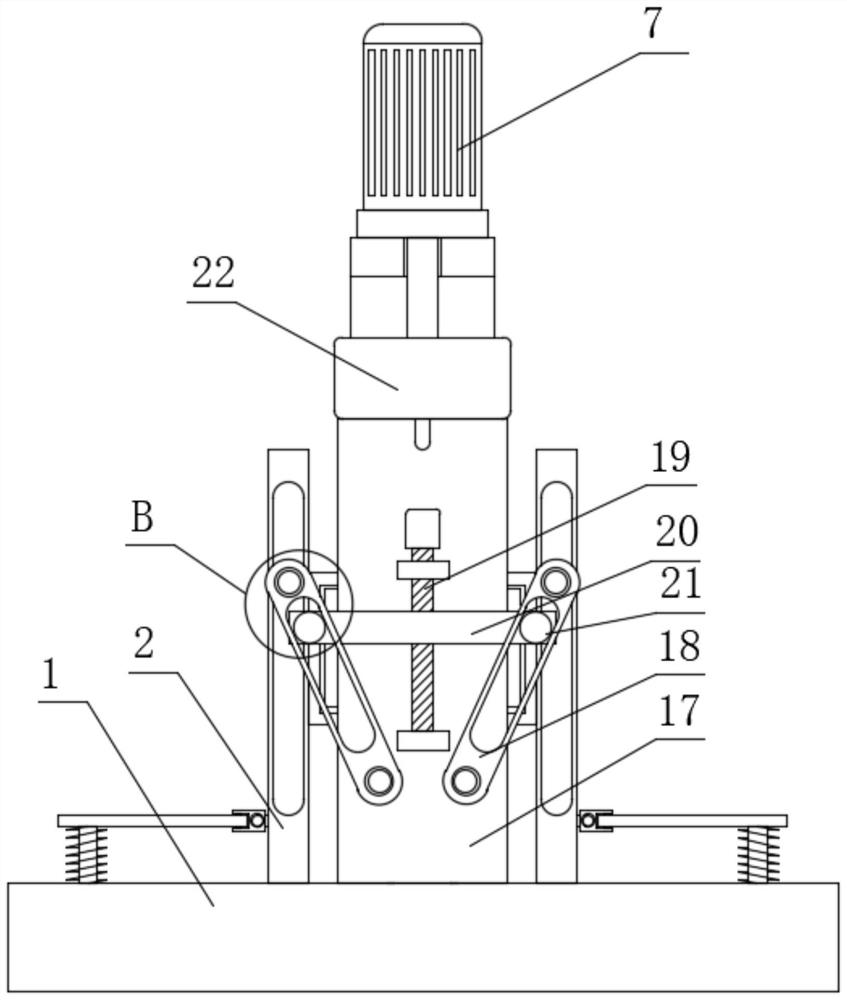

[0061] Embodiment two: if Figure 9-15 As shown, a high-efficiency motor rotor grinding equipment, the difference between this embodiment and Embodiment 1 is that: one side of the mounting plate 17 is rotatably connected with a mounting shaft 58 located in the fixed cover 37, and the mounting shaft 58 is located in the stepping Below the motor 47, the output shaft of the stepper motor 47 and one end of the installation shaft 58 are fixedly equipped with a synchronous wheel 48, and the two synchronous wheels 48 are driven and connected with the same synchronous belt 49, and the synchronous belt 49 moves the box 41 transmission connection , the other side of the moving box 41 is fixedly equipped with a slide bar 51, and a slip ring 52 is slidingly sleeved on the slide bar 51; 49 is fixedly connected, a support plate 44 is fixedly installed on one side of the fixed cover 37, and a rack 45 is fixedly installed on one side of the support plate 44, and a gear 46 is fixedly set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com