Special ceramic membrane treating agent for environment-friendly non-phosphorus electrophoresis and preparation method thereof, and method for forming membrane through treatment of treating agent

A technology of ceramic film layer and treatment agent, which is applied in the direction of electrophoretic plating, coating, electrolytic coating, etc., which can solve the problem of increasing treatment cost and management difficulty, high energy consumption of phosphating treatment technology, and large dependence on surface adjustment process, etc. problems, to achieve the effect of improving wear resistance and salt spray resistance, good salt spray resistance, wear resistance and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The mass ratio per kilogram of treatment agent is: 35g of fluozirconic acid, 86g of water-based resin, 40g of aminosilane or epoxysilane and 3g of dispersible nanoparticles, and the balance is water. The salt spray test time of the ceramic film layer formed by using this ratio after electrophoresis to form a paint surface can reach more than 1200 hours.

Embodiment 2

[0029] Embodiment 2: every kilogram of treating agent is by mass ratio: 40g fluorotitanic acid, 105g water-based resin, 42g of aminosilane or epoxy silane and 6g of dispersible nanoparticles, 15g MOSi2, acetone organic solvent, and the balance is water . The salt spray test time of the ceramic film layer formed by using this ratio after electrophoresis to form a paint surface can reach more than 1500 hours.

Embodiment 3

[0030] Embodiment 3: every kilogram of treating agent is by mass ratio: 45g fluorotitanic acid, 110g water-based resin, 46g of aminosilane or epoxy silane and 8g of dispersible nanoparticles, 18g MOSi2, acetone organic solvent, and the balance is water . The salt spray test time of the ceramic film layer formed by using this ratio after electrophoresis to form a paint surface can reach more than 1500 hours.

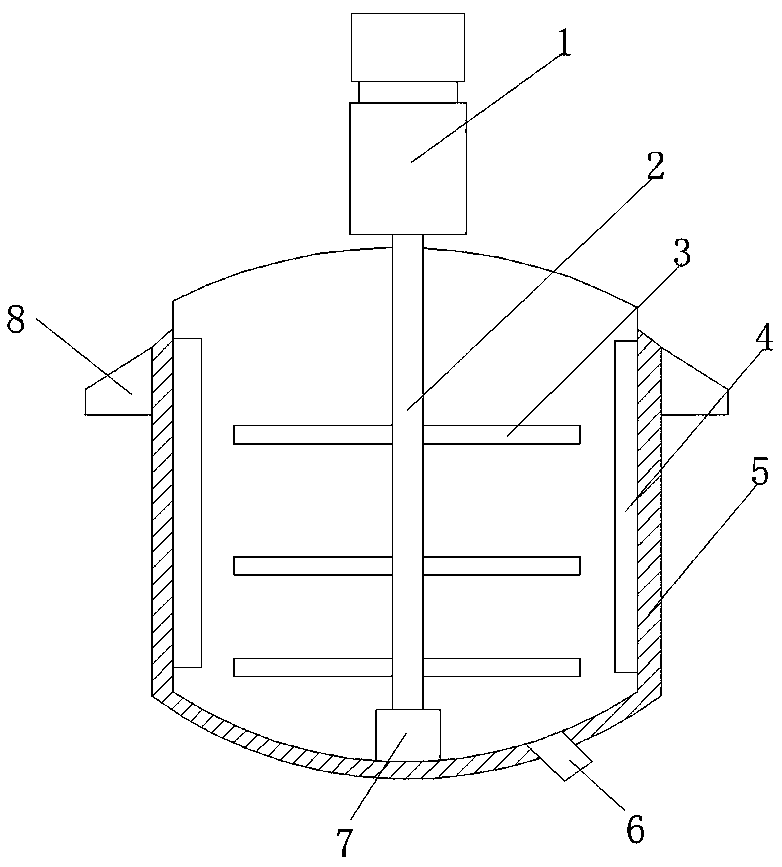

[0031] The preparation method of the above-mentioned environmentally friendly non-phosphorus electrophoresis special ceramic film layer treatment agent provided by the present invention comprises the steps of mixing the 30-50g of fluorozirconic acid or fluorotitanic acid, 80-120g of water-based resin, 30-50g of aminosilane and / or cyclic Oxysilane, 1-10g of dispersible nanoparticles and 10-20g of MOSi2 are added to the stirring tank in order to stir and mix with water, and the MOSi2 and water-based resin are stirred and mixed, then added to the acetone organic solvent, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com