A preparation method of encapsulating ink for inkjet printing of small particle size ceramics

A ceramic inkjet and wrapping technology, applied in ink, applications, household appliances, etc., can solve the problems of poor ink storage stability, inability to grind too fine, easy to produce precipitation, etc., to improve storage stability, full and bright hair color, rich The effect of pattern design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method for wrapping ink for ceramic inkjet printing, comprising the steps of:

[0033] 1) Mix the wrapped color material with the solvent, disperse evenly, and obtain the material to be ground;

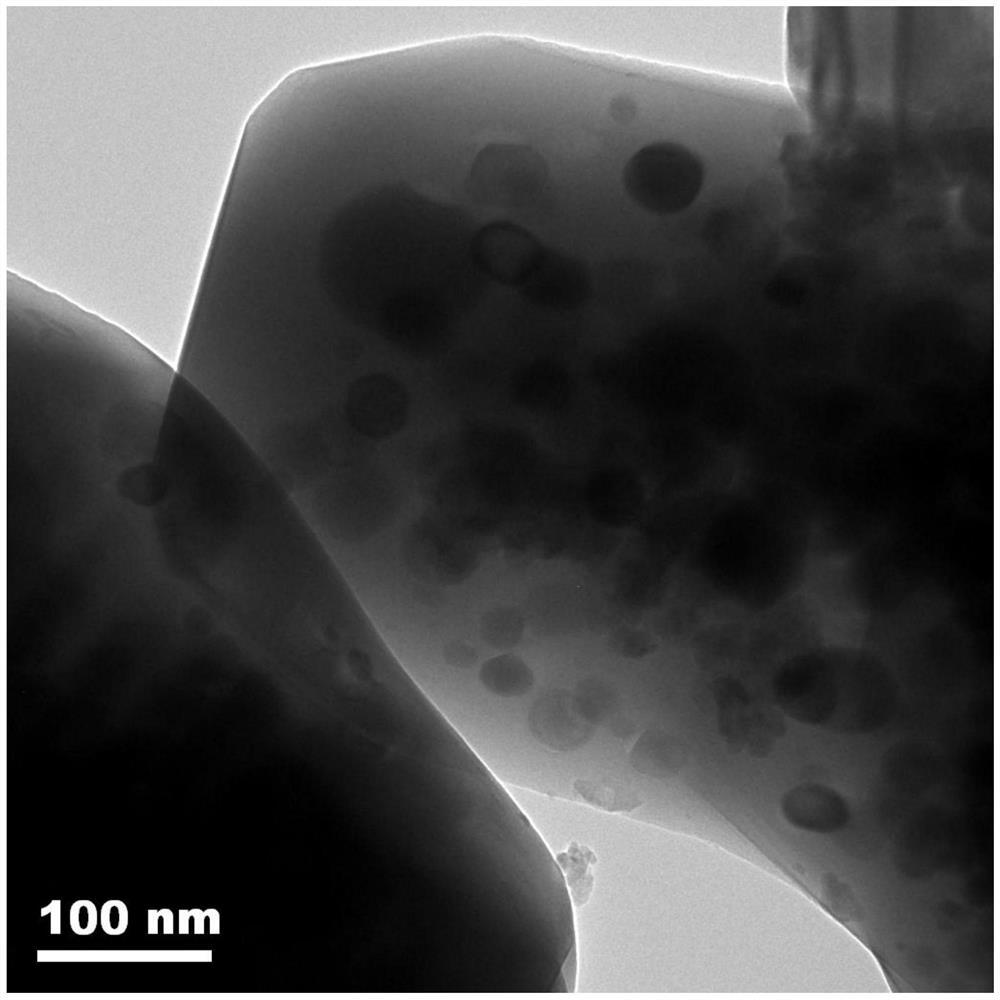

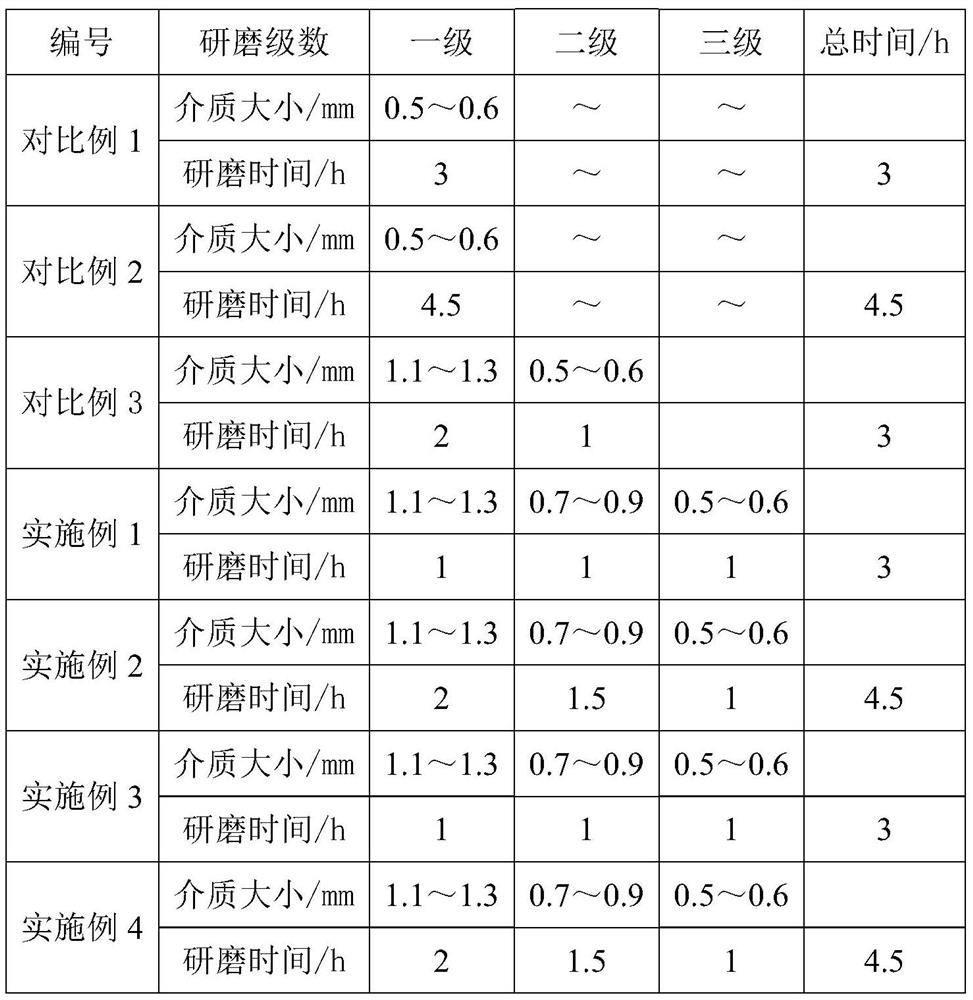

[0034] 2) Perform primary grinding on the abrasive to be ground, the size of the grinding medium is 1.0-1.5 mm, and grind until the average particle size of the color material is 1.0-1.3 μm to obtain the primary abrasive;

[0035] 3) performing secondary grinding on the primary grinding material, the size of the grinding medium is 0.7-1.0mm and smaller than that of the primary grinding medium, grinding until the average particle size of the color material is 0.7-0.9 μm, and obtaining the secondary grinding material;

[0036] 4) The secondary grinding material is subjected to tertiary grinding, the size of the grinding medium is 0.5-0.7 mm and smaller than that of the secondary grinding, and the average particle size of the color material is 0.5-0.6 μm, and the cer...

Embodiment 1

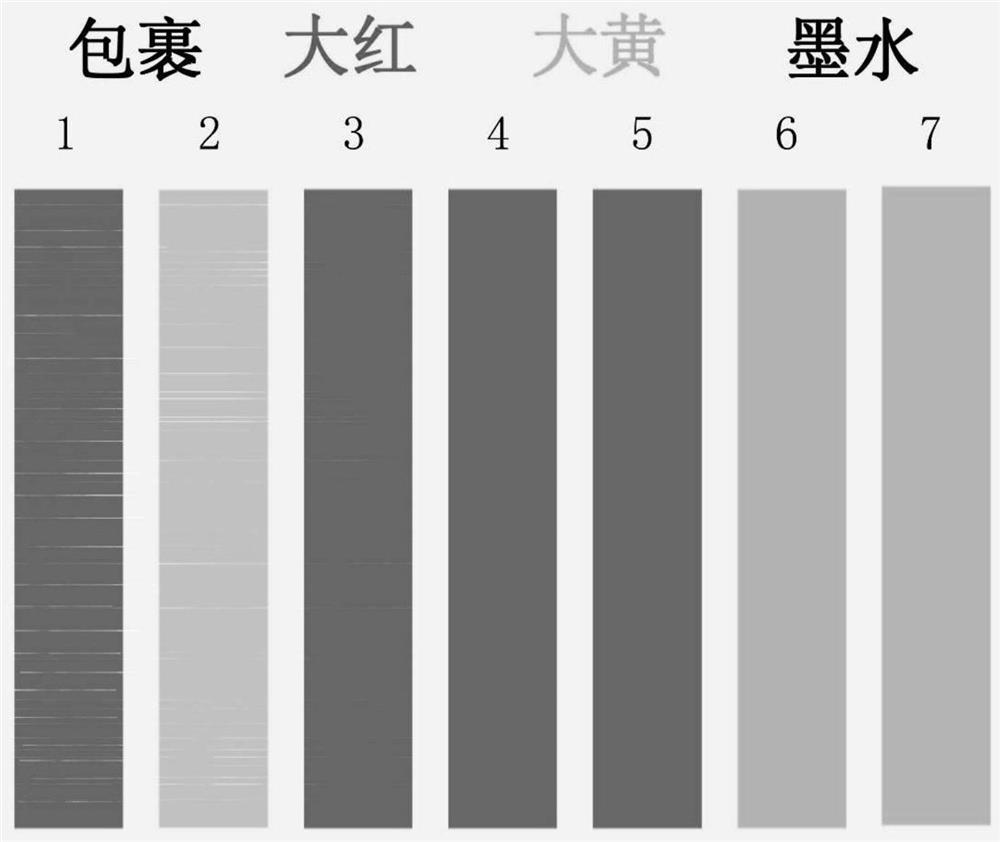

[0054] A wrapping ink for ceramic inkjet printing, consisting of the following components in terms of mass percentage: 50% wrapping colorant (zirconium silicate wrapping cadmium sulfur selenide bright red), 2% resin, 6% dispersant, leveling agent 0.1%, defoamer 0.1%, anti-settling agent 0.2%, and the balance is solvent.

Embodiment 2

[0056] A wrapping ink for inkjet printing of ceramics, composed of the following components by mass percentage: 50% wrapping colorant (zirconium silicate wrapping cadmium sulfur selenide bright red), 2.5% resin, 5.5% dispersant, leveling agent 0.1%, defoamer 0.1%, anti-settling agent 0.25%, and the balance is solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com