Electric vehicle thermal management system and control method thereof

A thermal management system and technology for electric vehicles, which are applied in the thermal management system of electric vehicles and their control fields, can solve the problems that heat cannot be recycled each other, the battery cooling demand is weak, and the heating demand is strong, so as to achieve good heating or cooling effect and improve The effect of energy utilization and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

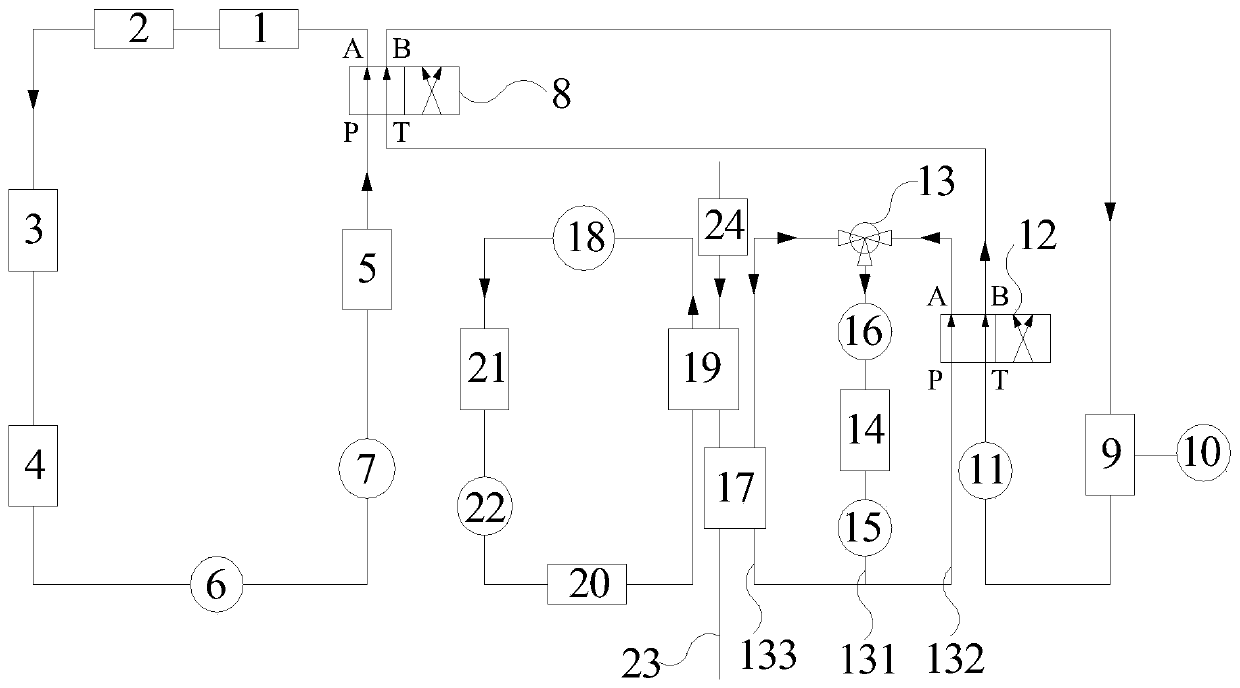

[0024] Such as figure 1 As shown, an electric vehicle thermal management system is designed for a certain model, including a motor cooling system, a battery thermal management system and a PTC electric heating system. The motor cooling system and the battery thermal management system are connected through the first reversing device 8, and the PTC The electric heating system and the battery thermal management system are connected through the second reversing device 12. When the first reversing device 8 and the second reversing device 12 are powered off, they are both in the non-reversing state, and the systems are independent circulation. In the commutation state, the battery thermal management system can be connected in series with the motor cooling sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com