Magnesium/steel layered composite material and preparation method thereof

A composite material and composite billet technology, applied in metal layered products, chemical instruments and methods, lamination, etc., can solve the problems of high equipment requirements, decreased interface bonding strength, interface cracking failure, etc., and achieves low equipment requirements and production. The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

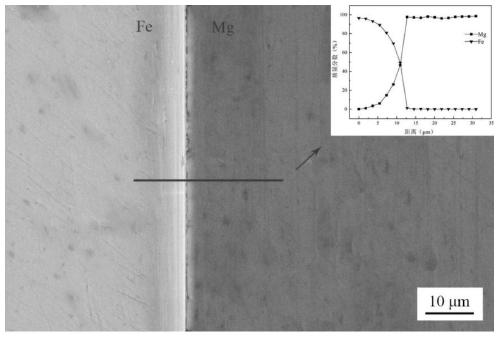

[0028] Preparation of Q235 steel / pure magnesium / Q235 steel layered composite material.

[0029]Using pure magnesium plate with a thickness of 7mm and Q235 steel plate with a thickness of 1.5mm as raw materials, the surface of the pure magnesium plate and Q235 steel plate to be compounded is treated by wire brush grinding method, and the pollution layer on the surface to be compounded is removed, so that the fresh metal is exposed , while obtaining the uneven surface structure and the grinding stripes perpendicular to the length direction of the pure magnesium plate and the Q235 steel plate, and obtaining the pure magnesium plate to be compounded and the Q235 steel plate to be compounded;

[0030] The pure magnesium plate to be compounded and the Q235 steel plate to be compounded are laminated and combined in the order of Q235 steel / pure magnesium / Q235 steel to form a composite billet, and the composite billet is wrapped with an aluminum foil sleeve with a thickness of 0.01mm, t...

Embodiment 2

[0036] Preparation of SUS310s steel / pure magnesium / Mn13 steel layered composites.

[0037] The pure magnesium plate with a thickness of 7.5mm, the SUS310s steel plate with a thickness of 1mm and the Mn13 steel plate with a thickness of 1.5mm are used as raw materials, and the surface of the pure magnesium plate, SUS310s steel plate and Mn13 steel plate to be composited is treated by grinding wheel grinding method, and the surface to be composited is removed. The pollution layer on the compound surface exposes the fresh metal, and at the same time obtains the uneven surface structure and the grinding stripes perpendicular to the length direction of the pure magnesium plate, SUS310s steel plate and Mn13 steel plate, and obtains the pure magnesium plate to be compounded, the SUS310s steel plate to be compounded and the Composite Mn13 steel plate;

[0038] The pure magnesium plate to be compounded, the SUS310s steel plate to be compounded and the Mn13 steel plate to be compounded ...

Embodiment 3

[0044] Preparation of 1Cr5Mo steel / pure magnesium / 1Cr5Mo steel layered composite material.

[0045] Using a pure magnesium plate with a thickness of 8mm and a 1Cr5Mo steel plate with a thickness of 0.5mm and 1mm as raw materials, the surface to be compounded of the pure magnesium plate and the 1Cr5Mo steel plate is treated by abrasive belt grinding to remove the contamination layer on the surface to be compounded. The fresh metal is exposed, and the uneven surface structure and the grinding stripes perpendicular to the length direction of the pure magnesium plate and the 1Cr5Mo steel plate are obtained at the same time, and the pure magnesium plate and the 1Cr5Mo steel plate to be compounded are obtained;

[0046] The pure magnesium plate to be compounded and the 1Cr5Mo steel plate to be compounded are laminated and combined in the order of 1Cr5Mo steel / pure magnesium / 1Cr5Mo steel to form a composite billet, and the composite billet is wrapped with an aluminum foil sleeve with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com