Novel chain boiler used during caustic soda production

A chain boiler, a new type of technology, applied in the direction of combustion air/fuel supply, combustion method, combustion equipment, etc., can solve the problems of unbalanced air supply, manual operation, excess oxygen, etc., to reduce smoke exhaust loss and work efficiency High and reduce the effect of blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

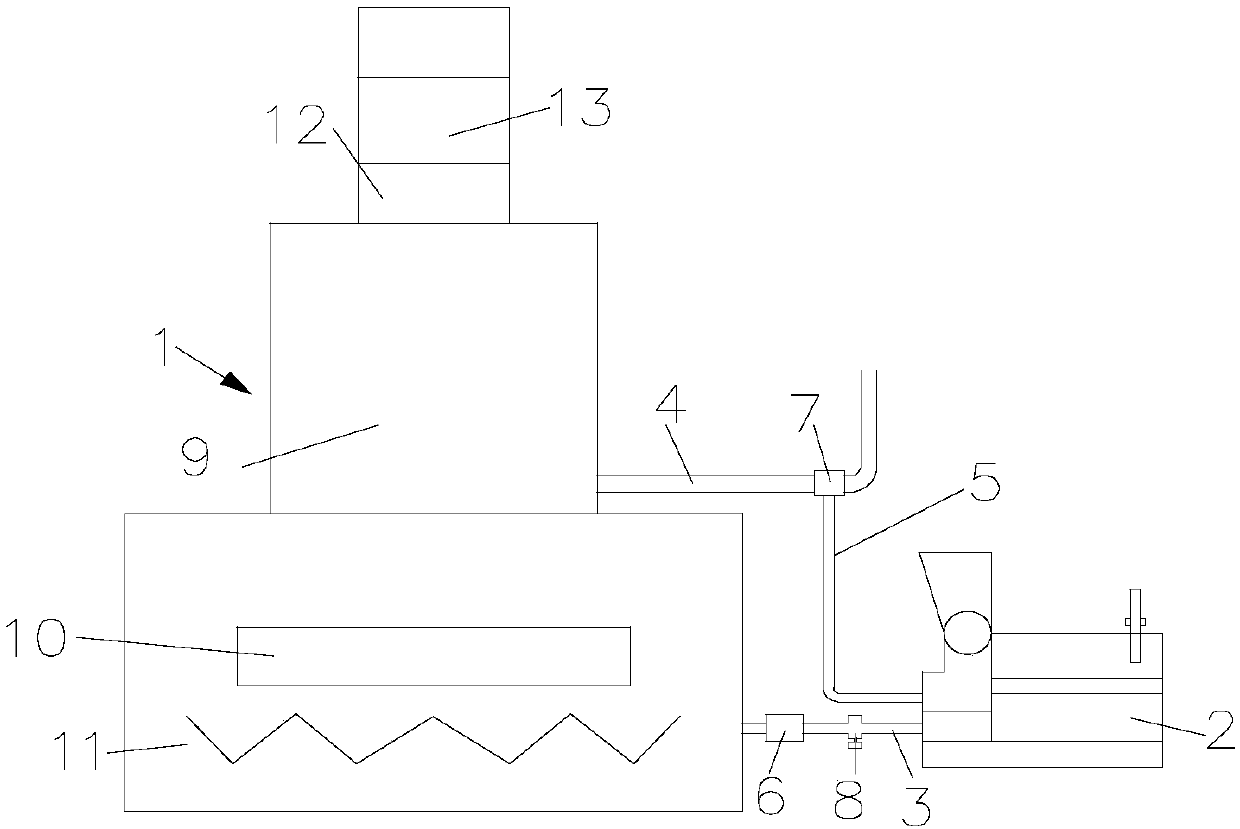

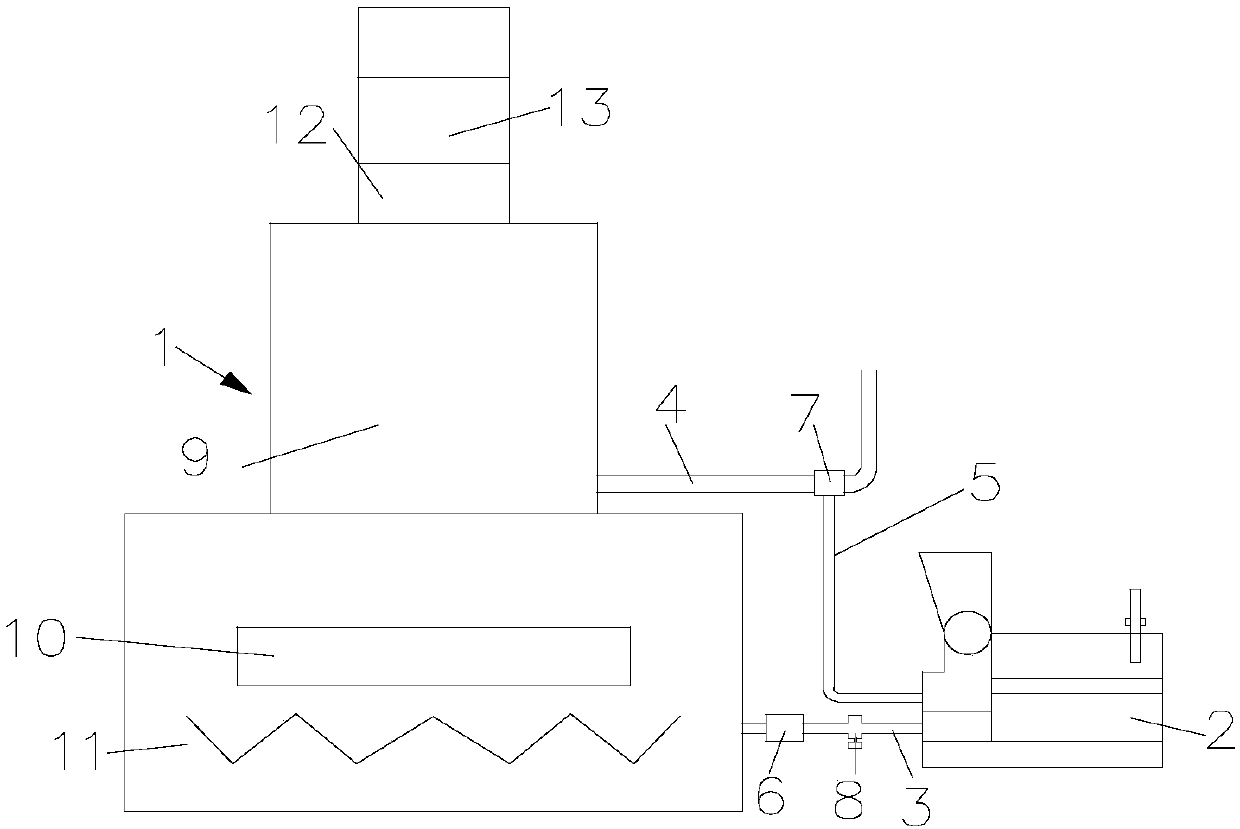

[0019] The following is attached figure 1 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

[0020] A new type chain boiler in the production of caustic soda, comprising a furnace body 1, a pulverized coal grinder 2, an air intake pipe 3, an exhaust gas output pipe 4, an exhaust gas recovery pipe 5 and an air conveying device 6, and the exhaust gas output pipe 4 is connected by bolts At one end of the furnace body 1, the waste gas is effectively discharged. One end of the waste gas recovery pipe 5 is connected to the waste gas output pipe 4. An electromagnetic air distribution valve 7 is arranged between the waste gas output pipe 4 and the waste gas recovery pipe 5. The electromagnetic air distribution The model of the valve 7 is TX DF2-00, which can recover and recycle the waste gas containing pulverized coal. The other end of the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com