FRP bellow-reinforcing composite bar

A technology of corrugated pipes and composite bars, applied in the directions of structural elements, building components, building reinforcements, etc., can solve the problems of unfavorable stress of composite bar structures, disappearance of the protective effect of steel bars, and reduced bearing capacity of composite bars, and achieve good corrosion resistance. Performance, corrosion avoidance, tensile deformation ability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

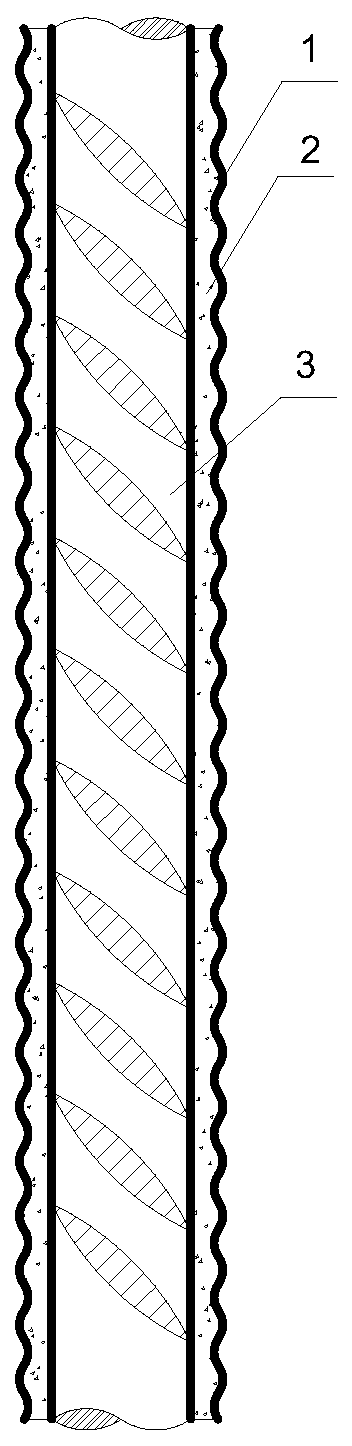

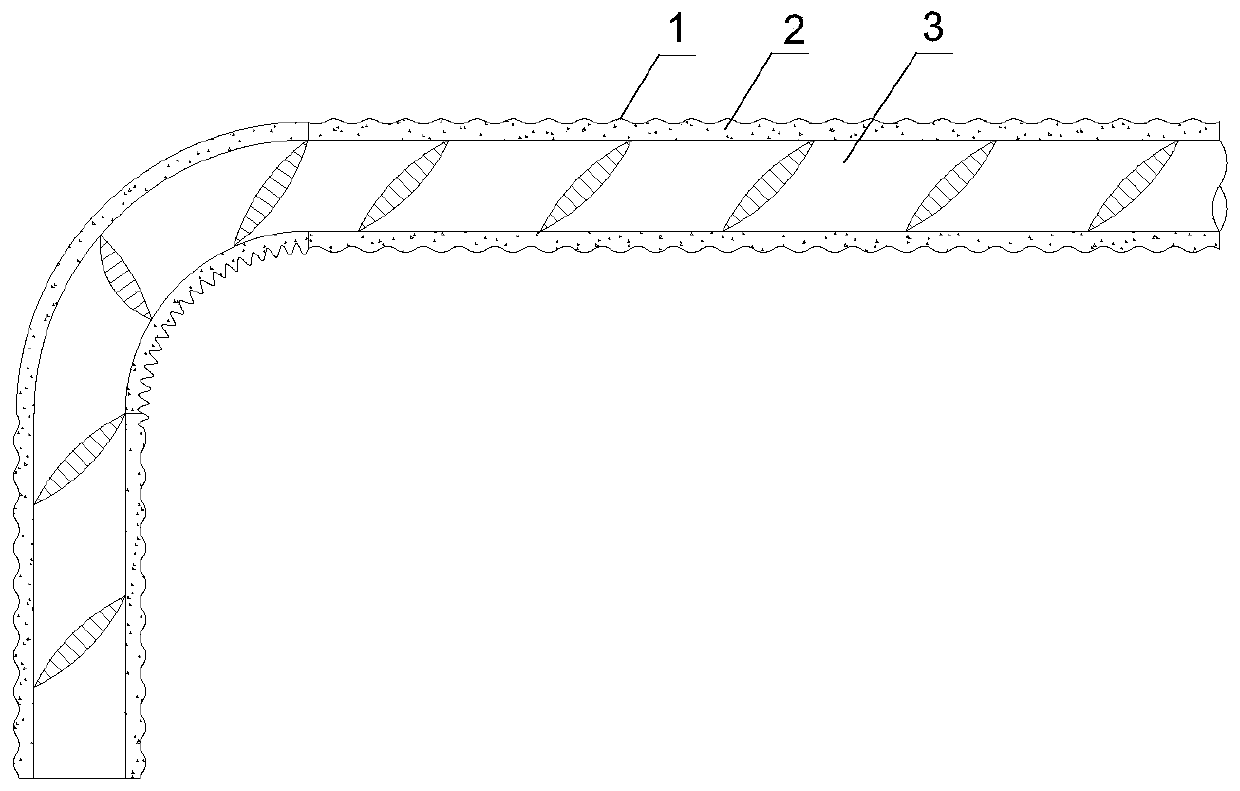

[0024] A method for preparing FRP corrugated pipe-steel bar composite bars, firstly design and process the corrugated inner film and outer mold according to the FRP corrugation, and pull the carbon fiber bundles through the pulling device at a certain pultrusion rate, and the carbon fiber bundles are drawn from the pultrusion machine The creel is removed from the creel and enters the dipping tank filled with epoxy resin. The fiber bundles are fully impregnated evenly by the resin matrix, and then pass through the corrugated inner membrane circularly. Circular high-temperature die, overall solidified molding. The corrugated inner film and corrugated outer mold are removed, and the preliminarily cured FRP corrugated pipe is further cured at a high temperature in a post-curing furnace to form a circular corrugated pipe of continuous fiber reinforced resin composite material. Insert the ribbed steel bar into the FRP corrugated pipe after high-temperature curing and temporarily fix...

Embodiment 2

[0026] A preparation method of FRP bellows-steel bar composite bar, the ribbed steel bar is passed through the dipping tank equipped with epoxy resin, so that the surface of the ribbed steel bar is evenly coated with a certain thickness of epoxy resin glue, and the carbon fiber bundle is passed through the Under the traction of the pulling device at a certain pultrusion rate, the carbon fiber bundles fall from the creel of the pultrusion machine and enter the impregnation tank filled with epoxy resin. The ribbed steel bar with epoxy resin glue is bonded with the epoxy resin glue around the ribbed steel bar, and then passed through the circular high-temperature die, and the whole is cured and formed. Put the cured and molded composite bar into post-curing equipment for post-curing to obtain the FRP bellows-steel bar composite bar of the present invention.

[0027] The outer FRP corrugated pipe of the composite rib adopts one fiber or a combination of multiple fibers among carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com