Chrysanthemum fermentation product and preparation method thereof

A technology for fermented products and chrysanthemum, applied in the field of fermentation technology, can solve the problems of loss of functional components, poor health care function of chrysanthemum fermented products, failure to effectively retain and other problems, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

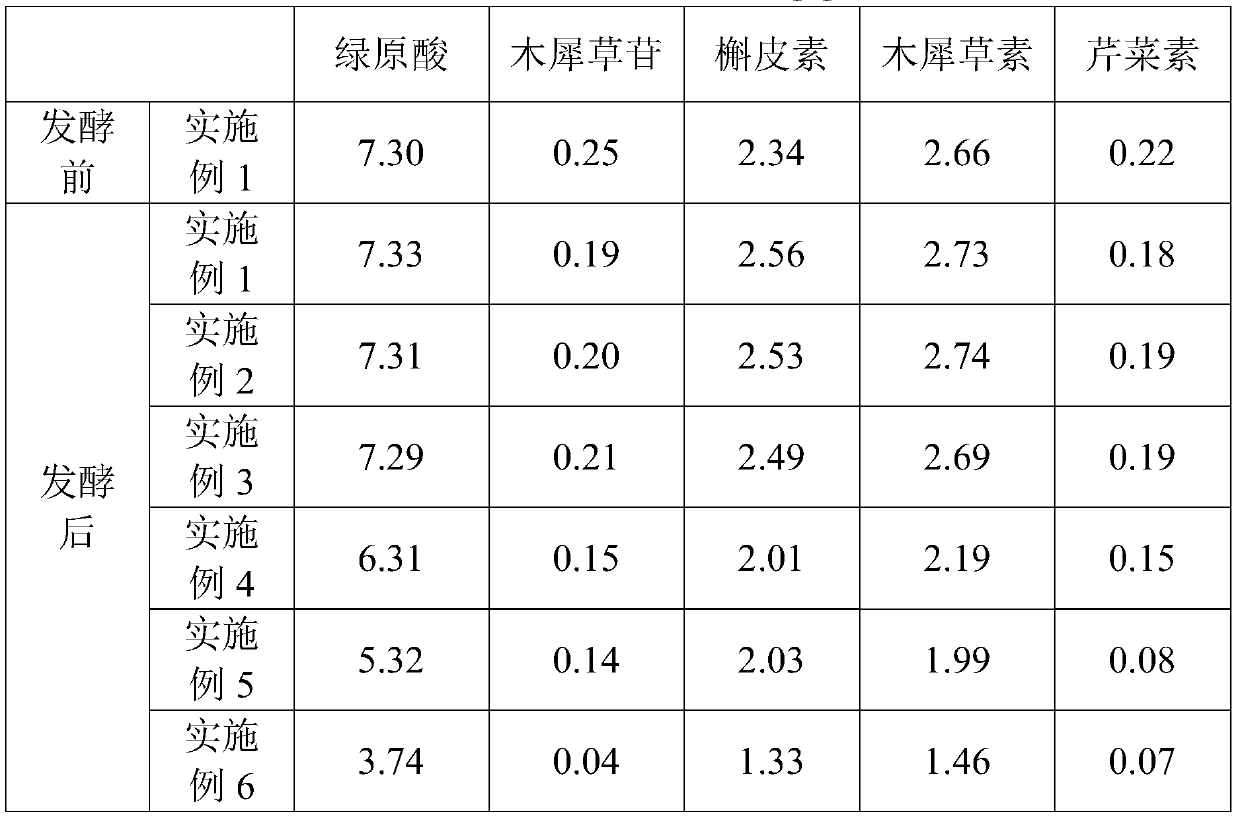

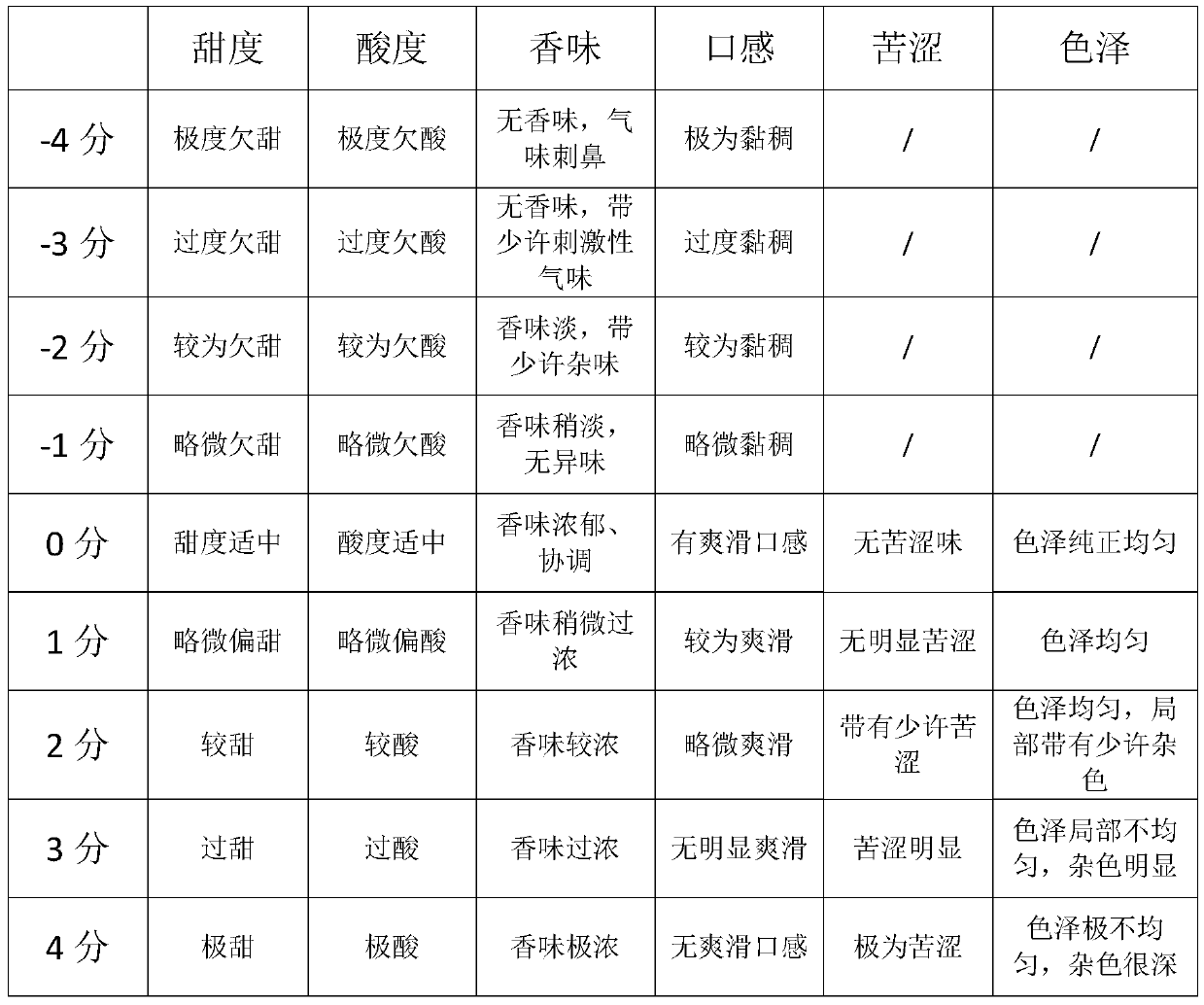

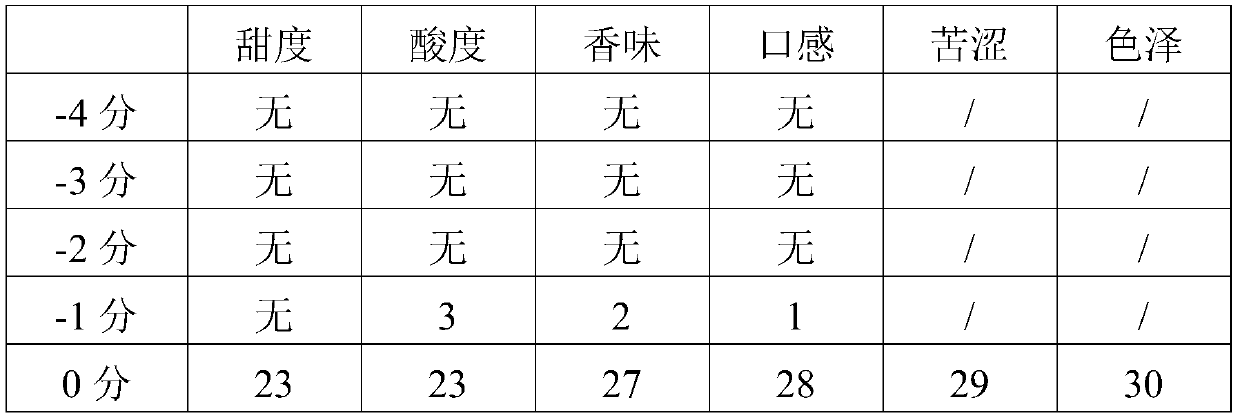

Examples

Embodiment 1-3

[0057] In the following examples 1-3:

[0058] The used Lactobacillus paracasei (Lactobacillus paracasei) is self-made by the inventor and has been preserved in the General Microbiology Center (CGMCC) of the China Committee for the Collection of Microbial Cultures on October 16, 2017. Its address is Beichen West, Chaoyang District, Beijing No. 3, Courtyard No. 1, the preservation number is CGMCC No.14813;

[0059] The Lactobacillus brevis used was self-made by the inventor and was deposited in the General Microorganism Center of China Committee for the Collection of Microbial Cultures on October 16, 2017, with the preservation number CGMCC No.14811.

[0060] In the following examples, Leuconostoc enterica, Lactobacillus casei and Lactobacillus plantarum were all provided by China Industrial Microorganism Culture Collection Management Center (abbreviated as CICC), wherein the strain number of Leuconostoc enteritidis was CICC 22241, Lactobacillus casei The strain number of Lactob...

Embodiment 1

[0063] The present embodiment provides a kind of preparation method of chrysanthemum fermented product, comprises the following steps:

[0064] 1. Rehydrate and beat the cleaned fresh Bochrysanthemum with 1.5 times the quality of pure water to obtain chrysanthemum pulp.

[0065] 2. Wheat protein peptide powder, corn protein peptide powder, glucose, sodium acetate, potassium dihydrogen phosphate, magnesium sulfate and Tween 80 were dissolved with chrysanthemum extract, and the culture medium was prepared. Among them, the mass content of each component in the culture medium is respectively: 0.6% of wheat protein peptide powder, 0.6% of corn protein peptide powder, 0.3% of glucose, 0.3% of sodium acetate, 0.1% of potassium dihydrogen phosphate, 0.01% of magnesium sulfate, Wen 80 0.05%, the balance of chrysanthemum extract.

[0066] 3. Divide the prepared culture medium into five parts, sterilize them at a temperature of about 85°C for about 30 minutes, cool to 37±1°C, and insert...

Embodiment 2

[0071] The present embodiment provides a kind of preparation method of chrysanthemum fermented product, comprises the following steps:

[0072] 1. Rehydrate and beat the cleaned fresh Bochrysanthemum with purified water of the same quality to obtain chrysanthemum pulp.

[0073] 2. Wheat protein peptide powder, corn protein peptide powder, glucose, sodium acetate, potassium dihydrogen phosphate, magnesium sulfate and Tween 80 were dissolved with chrysanthemum extract, and the culture medium was prepared. Among them, the mass content of each component in the medium is: wheat protein peptide powder 1%, corn protein peptide powder 1%, glucose 0.8%, sodium acetate 0.8%, potassium dihydrogen phosphate 0.5%, magnesium sulfate 0.03%, spit Wen 80 0.2%, the balance of chrysanthemum extract.

[0074] 3. Divide the prepared culture medium into five parts, sterilize them at a temperature of about 85°C for about 30 minutes, cool to 37±1°C, and insert Lactobacillus brevis, Leuconostoc enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com