A modular light-weight green sloped roof system and construction method

A roofing system and slope technology, applied in the direction of roofing, roof covering, buildings, etc., can solve the problems of heavy roof load, complicated laying, blockage of drainage pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

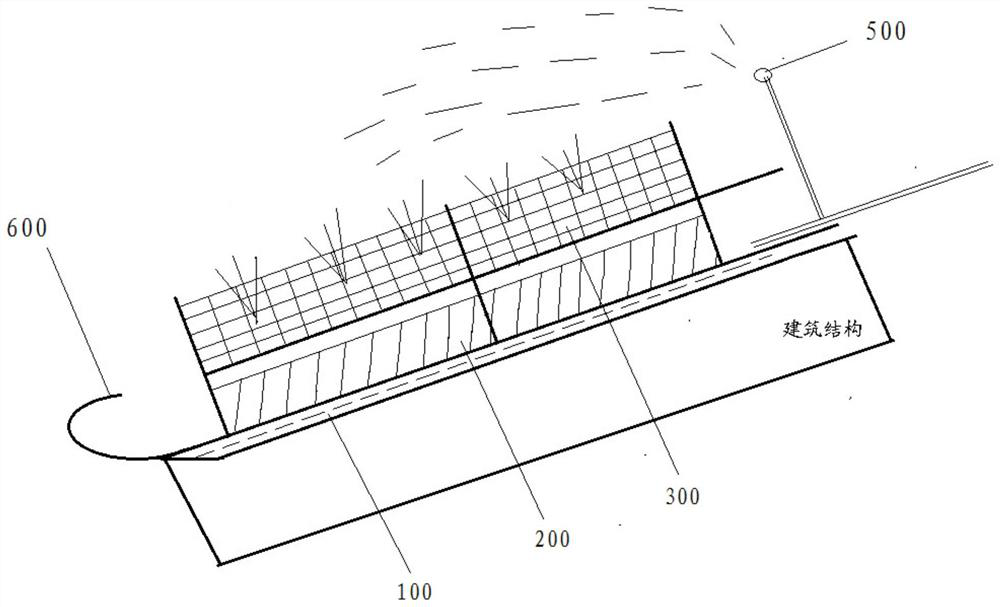

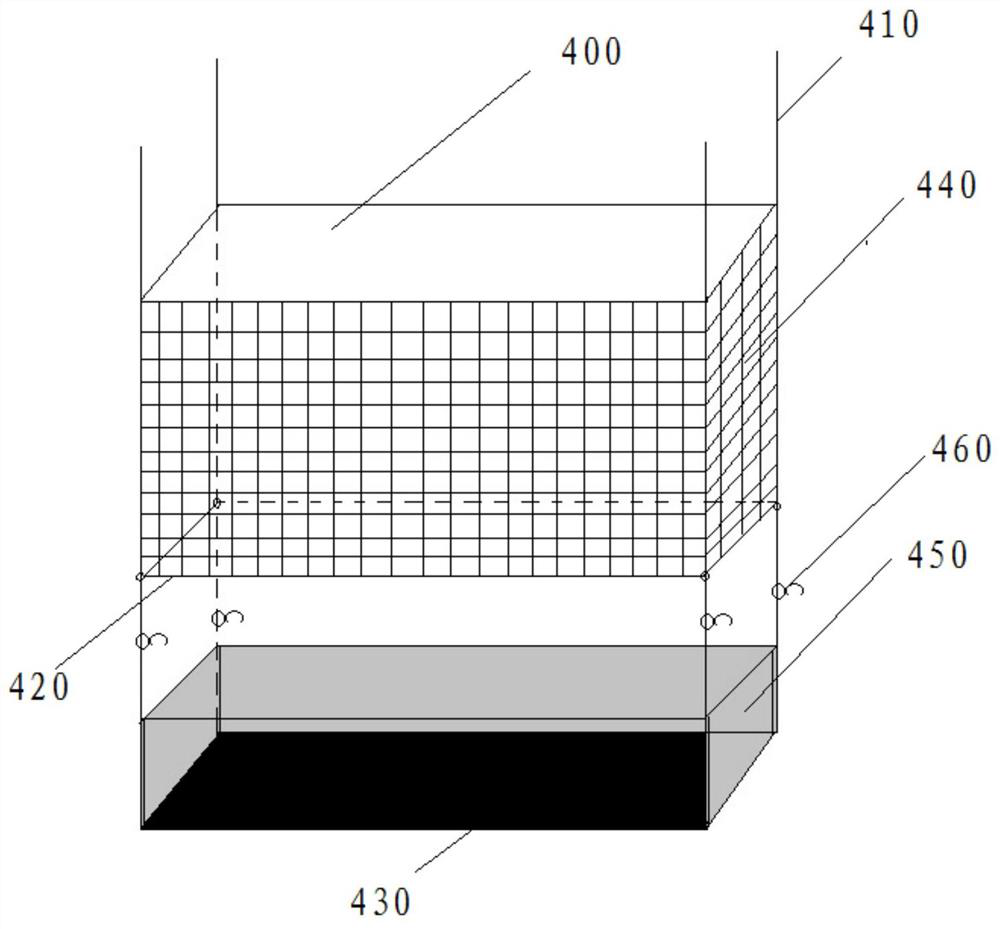

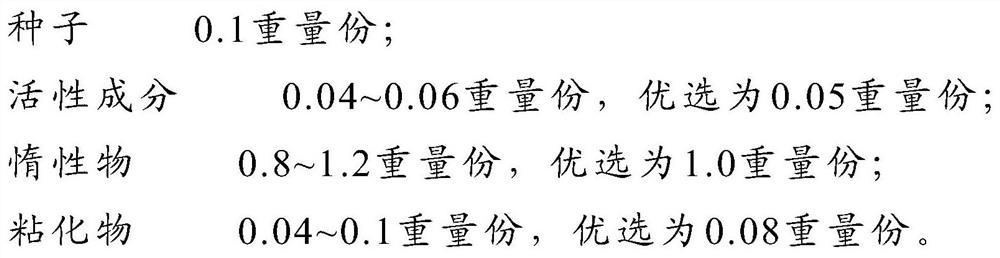

[0132] A construction method of a green slope roof system, which is used to construct residential roofs such as figure 1 and figure 2 Roof system shown. The PET self-adhesive waterproof roll material (thickness is 2.0cm, surface resistance 0.05Ω) that surface is sprayed with copper coating is laid on roof, and roll material is closely connected with roof; Arrange planting row 400 on waterproof roll material, described planting The row 400 is a two-layer rectangular frame structure, including four support columns 410, and a middle net plate 420 and a non-porous bottom plate 430 respectively fixed in the length interval of the support column 410 and at the bottom; There are bottom stoppers 450 around the base plate 430, the bottom stoppers 450 are highly in contact with the middle net plate 420, the upper part is a guard plate with holes or a guard net, and the lower part is a guard plate without holes. The water filter layer 200 is laid on the bottom plate 430 , and the plan...

Embodiment 2

[0137] A construction method of a green slope roof system, used to construct such as figure 1 and figure 2 Roof system shown. This roofing system is the same as in Embodiment 1, the only difference is that about 2 × 10 8 CFU / g phosphorus accumulating bacteria, 2×10 8 CFU / g denitrifying bacteria and 2×10 8 CFU / g nitrifying bacteria.

Embodiment 3

[0139] A construction method of a green slope roof system, used to construct such as figure 1 and figure 2 Roof system shown. The roof system is the same as that in Embodiment 1, the only difference is that the water filter layer is only made of zeolite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com