Anti-slip wood-plastic floor and production method

A technology of wood-plastic floor and production method, applied in the field of wood-plastic floor, can solve the problems of poor anti-skid performance, low wear coefficient and elastic coefficient of the floor, and achieve the advantages of easy popularization and promotion, low brittleness and high elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

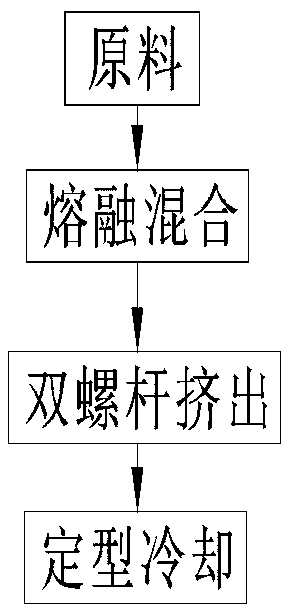

Image

Examples

Embodiment 1

[0049] Embodiment 1. The raw materials used in the manufacture of non-slip wood-plastic flooring are as follows in parts by weight:

[0050] 15-16 parts of resin, 13-14 parts of styrene-butadiene rubber, 30-40 parts of wood powder, 3-4 parts of silicon dioxide, 6-9 parts of epoxy resin, 15-20 parts of calcium carbonate, 5- 8 parts, 2-3 parts of coupling agent, 2-3 parts of other additives.

[0051] S1: Add styrene-butadiene rubber, resin, plasticizer oil and toughening agent into the melting furnace according to the above weight, and add other additives to melt at the same time;

[0052] S2: Then add silicon dioxide, epoxy resin, calcium carbonate, plasticizer oil and coupling agent into the melting furnace, stir at high speed for 15-20 minutes to granulate;

[0053] S3: Extrude the mixed raw material obtained in S2 through a twin-screw extruder, and the temperature of each zone of the extruder is:

[0054] Zone 1 temperature: 160~165℃,

[0055] Zone 2 temperature: 165~170℃...

Embodiment 2

[0063] Embodiment 2. The raw materials used in the manufacture of non-slip wood-plastic flooring are as follows in parts by weight:

[0064] 16-17 parts of resin, 14-15 parts of styrene-butadiene rubber, 30-40 parts of wood powder, 3-4 parts of silicon dioxide, 6-9 parts of epoxy resin, 15-20 parts of calcium carbonate, 5- 8 parts, 2-3 parts of coupling agent, 3 parts of toughening agent, 2-3 parts of other additives.

[0065] S1: Add styrene-butadiene rubber, resin, plasticizer oil and toughening agent into the melting furnace according to the above weight, and add other additives to melt at the same time;

[0066] S2: Then add silicon dioxide, epoxy resin, calcium carbonate, plasticizer oil and coupling agent into the melting furnace, stir at high speed for 15-20 minutes to granulate;

[0067] S3: Extrude the mixed raw material obtained in S2 through a twin-screw extruder, and the temperature of each zone of the extruder is:

[0068] Zone 1 temperature: 160~165℃,

[0069]...

Embodiment 3

[0077] Embodiment 3, the raw materials used in the manufacture of anti-skid type wood-plastic floor are as follows in parts by weight:

[0078] 16-17 parts of resin, 15-16 parts of styrene-butadiene rubber, 30-40 parts of wood powder, 3-4 parts of silicon dioxide, 6-9 parts of epoxy resin, 15-20 parts of calcium carbonate, 5- 8 parts, 2-3 parts of coupling agent, 3-4 parts of toughening agent, 2-3 parts of other additives.

[0079] S1: Add styrene-butadiene rubber, resin, plasticizer oil and toughening agent into the melting furnace according to the above weight, and add other additives to melt at the same time;

[0080] S2: Then add silicon dioxide, epoxy resin, calcium carbonate, plasticizer oil and coupling agent into the melting furnace, stir at high speed for 15-20 minutes to granulate;

[0081] S3: Extrude the mixed raw material obtained in S2 through a twin-screw extruder, and the temperature of each zone of the extruder is:

[0082] Zone 1 temperature: 160~165℃,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com