Method for manufacturing super two-phase stainless steel large-sized sea water pump shaft

A duplex stainless steel and manufacturing method technology, applied in metal processing equipment, etc., can solve problems such as poor thermoplasticity, low yield rate of finished products, and difficulty in manufacturing large parts, and achieve the effect of good thermoplasticity and high yield rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

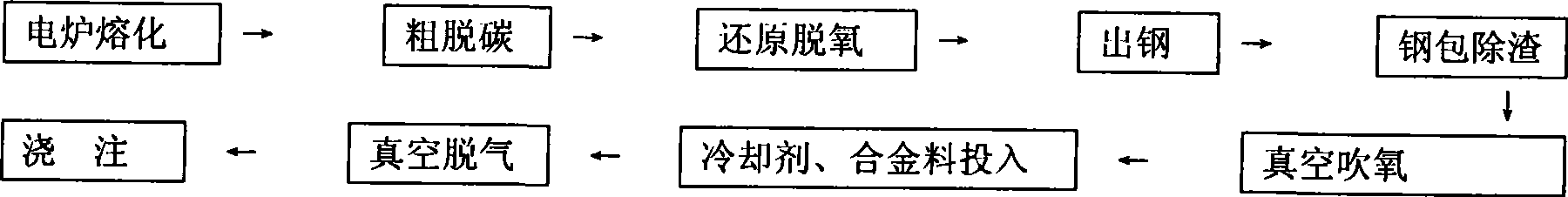

[0012] Such as figure 1 The smelting process of 00Cr25Ni7Mo3WCuN duplex stainless steel: melting the charge in an electric arc furnace (C: 0.8-1.5%, Cr: 24%, Ni: 7%, T: 1580°C) → rough decarburization (C: 0.3-0.5%, Cr: 20~22.5%, Ni: 6.5~7.0%, T: 1650~1750℃) → reduction deoxidation (C: 0.3~0.5%, Cr: 23~24%, Ni: 6.5~7.0%, T: 1680~ 1700°C) → tapping → ladle deslagging → vacuum oxygen blowing (C: ≤0.02%, Cr: 22.5-23.5%, Ni: 6.5-7.0%, T: 1700-1750°C) → coolant, alloy material input ( C: ≤0.02%, Cr: 23.5~25%, Ni: 7.5%, T: 1660~1680℃→vacuum degassing (C: ≤0.02%, Cr: 24.5~25%, Ni: 7.5%, T: 1600 ~1650°C)→Pouring into 28″plum blossom ingot.

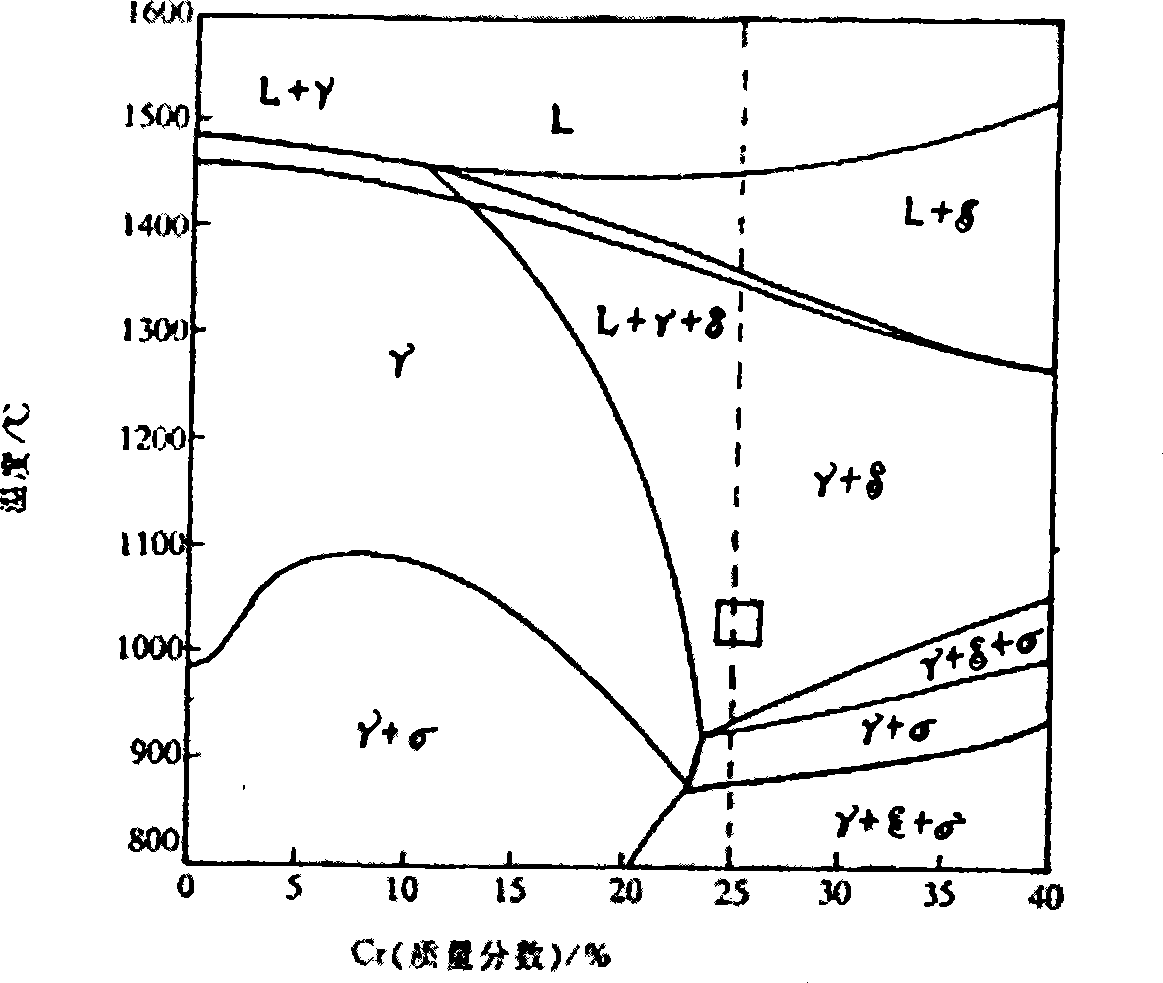

[0013] Such as figure 2 For this steel type, the σ phase can be gradually dissolved in austenite or transfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com