Vegetable oil/inorganic nano particle composite super-hydrophobic coating solution and its preparation method and application

A technology of inorganic nanoparticles and super-hydrophobic coating, applied in the direction of coating, etc., can solve problems such as harsh process conditions, complicated preparation process, and expensive raw materials, and achieve simple preparation methods, stable super-hydrophobic performance, and wide sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Preparation of tung oil-based mercaptan: Mix 7.8g of 2-mercaptoethanol and 11g of tung oil evenly, add 0.22g of initiator 2-hydroxy-2-methyl-1-phenylacetone, mix evenly and put them under ultraviolet light React under light irradiation for 6 hours to obtain tung oil polyol; disperse 10.5 g of tung oil polyol and 6.3 g of mercaptopropionic acid in 100 mL of toluene and stir evenly, react at 110 °C for 6 h under the action of 0.34 g of p-toluenesulfonic acid, and finally The product was dispersed in 100 mL of ethyl acetate, and after washing with water and rotary evaporation to remove the solvent, tung oil-based mercaptan was obtained;

[0019] 2) Mix 1 g of tung oil mercaptan and 0.5 g of octavinyl POSS evenly, add 3 mg of 2-hydroxy-2-methyl-1-phenylacetone and disperse evenly, and finally add 15 mL of tetrahydrofuran for dilution to form a coating solution;

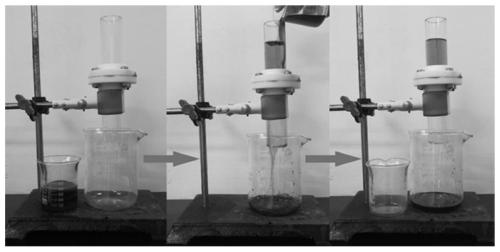

[0020] 3) Coating the coating solution on glass flakes, cotton cloth, metal mesh, filter paper and wood by sp...

Embodiment 2

[0023] 1) Preparation of tung oil-based mercaptan: Mix 7.8g of 2-mercaptoethanol and 11g of tung oil evenly, add 0.22g of initiator 2-hydroxy-2-methyl-1-phenylacetone, mix evenly and put them under ultraviolet light React under light irradiation for 6 hours to obtain tung oil polyol; disperse 10.5 g of tung oil polyol and 6.3 g of mercaptopropionic acid in 100 mL of toluene and stir evenly, react at 110 °C for 6 h under the action of 0.34 g of p-toluenesulfonic acid, and finally The product was dispersed in 100 mL of ethyl acetate, and after washing with water and rotary evaporation to remove the solvent, tung oil-based mercaptan was obtained;

[0024] 2) Mix 1g tungyl mercaptan and 0.5 g octavinyl POSS evenly, add 3 mg of 2-hydroxy-2-methyl-1-phenylacetone and 0.15 g of SiO 2 Nanoparticles are uniformly dispersed, and finally 15mL tetrahydrofuran is added to dilute to form a coating solution;

[0025] 3) Coating the coating solution on glass flakes, cotton cloth, metal mesh,...

Embodiment 3

[0028] 1) Preparation of tung oil-based mercaptan: Mix 7.8g of 2-mercaptoethanol and 11g of tung oil evenly, add 0.22g of initiator 2-hydroxy-2-methyl-1-phenylacetone, mix evenly and put them under ultraviolet light React under light irradiation for 6 hours to obtain tung oil polyol; disperse 10.5 g of tung oil polyol and 6.3 g of mercaptopropionic acid in 100 mL of toluene and stir evenly, react at 110 °C for 6 h under the action of 0.34 g of p-toluenesulfonic acid, and finally The product was dispersed in 100 mL of ethyl acetate, and after washing with water and rotary evaporation to remove the solvent, tung oil-based mercaptan was obtained;

[0029] 2) Mix 1g tungyl mercaptan and 0.5 g octavinyl POSS evenly, add 3 mg of 2-hydroxy-2-methyl-1-phenylacetone and 0.3 g of SiO 2 Nanoparticles are uniformly dispersed, and finally 15mL tetrahydrofuran is added to dilute to form a coating solution;

[0030] 3) Coating the coating solution on glass flakes, cotton cloth, metal mesh, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com