Wear-resistant superomniphobic material and preparation method thereof

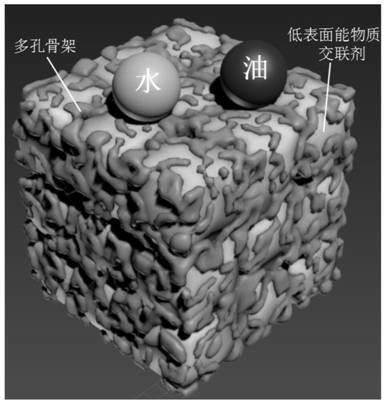

A super-lyophobic and wear-resistant technology, applied in the field of super-lyophobic materials, can solve the problems of easy adhesion of liquid on the wear place, large pores of the porous skeleton, failure of the super-lyophobic surface, etc., and achieve excellent wear resistance, High mechanical strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] (2) Preparation of fluorinated epoxy resin

[0052] Take a certain mass ratio of diethylenetriamine and heptafluorobutyric acid, add a certain volume of acetone solution, and then stir to react to form a transparent mixed solution. A certain quality of epoxy resin is added to the above mixed solution and magnetically stirred to obtain a black uniform fluorinated epoxy resin solution.

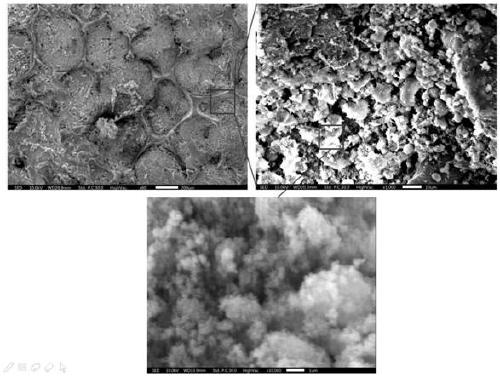

[0053] (3) Preparation of lyophobic composite liquid

[0054] Take a certain mass ratio of 1H, 1H, 2H, 2H-perfluorodecyltrimethoxysilane and inorganic nanoparticles, add them to a certain volume of ethanol solution, and stir magnetically to prepare a hydrophobic coating solution similar to paint. Then, the fluorinated epoxy resin, silane coupling agent, and dispersant prepared in step (1) are added to the hydrophobic coating liquid, and magnetically stirred to obtain a lyophobic composite liquid.

[0055] (4) Preparation of super lyophobic materials

[0056] The roughened foamed copper prepared i...

Embodiment 1

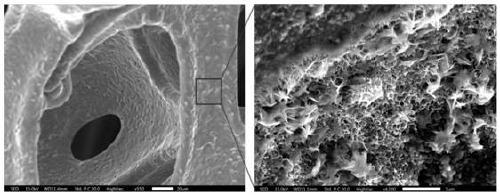

[0059] (1) Roughening of foamed copper: First, wash the foamed copper with absolute ethanol and dilute hydrochloric acid with a concentration of 2mol / L for 10 minutes, then repeatedly rinse with deionized water and dry for use; then, soak the sample at room temperature Take the 1mol / L NaOH solution as the anode, use the titanium dioxide as the cathode, and the current density of 0.1A / cm2. After reacting for 10 min, take it out and dry it with cold air to obtain roughened foamed copper.

[0060] (2) Preparation of fluorinated epoxy resin: Take 2g of diethylenetriamine and 8g of heptafluorobutyric acid, add them to 80mL of acetone solution, and then stir and react at a low speed for 10 minutes at 100°C to form a transparent mixed solution. Finally, a certain quality of epoxy resin was added to the above mixed solution, and after magnetic stirring at 60°C for 70 minutes, a black uniform fluorinated epoxy resin solution was obtained.

[0061] (3) Preparation of lyophobic composite solu...

Embodiment 2

[0064] (1) Roughening of foamed iron: Soak the foamed iron in a four-in-one phosphating solution (40min), then take it out and dry it (not washable) to obtain a dark gray roughened phosphating film.

[0065] (2) Preparation of fluorinated epoxy resin: Take 2g of diethylenetriamine and 8g of heptafluorobutyric acid, add them to 80mL of acetone solution, and then stir and react at 80°C for 20min at low speed to form a transparent mixed solution. Finally, a certain quality of epoxy resin was added to the above mixed solution, and after magnetic stirring at 50°C for 70 minutes, a black uniform fluorinated epoxy resin solution was obtained.

[0066] (3) Preparation of lyophobic composite solution: Take 1.2g of 1H, 1H, 2H, 2H-perfluorodecyltrimethoxysilane and 4g of titanium dioxide nanoparticles (40nm), add them to 40mL of ethanol solution, at 40℃, pH= After magnetic stirring for 2 hours under 5 conditions, hydrophobic titanium dioxide nanoparticles were prepared. Then, add 0.9g of flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com