Carbon-based composite iron cyanamide material and preparation method thereof, and sodium ion battery adopting carbon-based composite iron cyanamide material as negative electrode material

A composite ferric cyanamide and carbon-based technology, which is applied in the field of electrochemical materials, can solve the problems of limited material application and difficulty in obtaining composite structures, and achieve uniform shape distribution, improved electrical conductivity and cycle reversibility, and large growth opportunities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The carbon-based composite iron cyanamide material is prepared by the following steps:

[0023] 1) Take 1 g of analytically pure ferricamine oxalate, 2 g of urea, and 0.1 g of CNT according to the mass ratio of 1:2:0.1, and place them in a glass mortar and grind them thoroughly to obtain a fine and uniform light green mixture powder. The product is recorded as A;

[0024] 2) Add 0.02g of EDTA to the product A, dissolve it in water, and disperse it ultrasonically for 10 minutes, then put it into a freeze dryer, and dry it at -50°C for 12 hours to obtain a completely dry black product, which is designated as B;

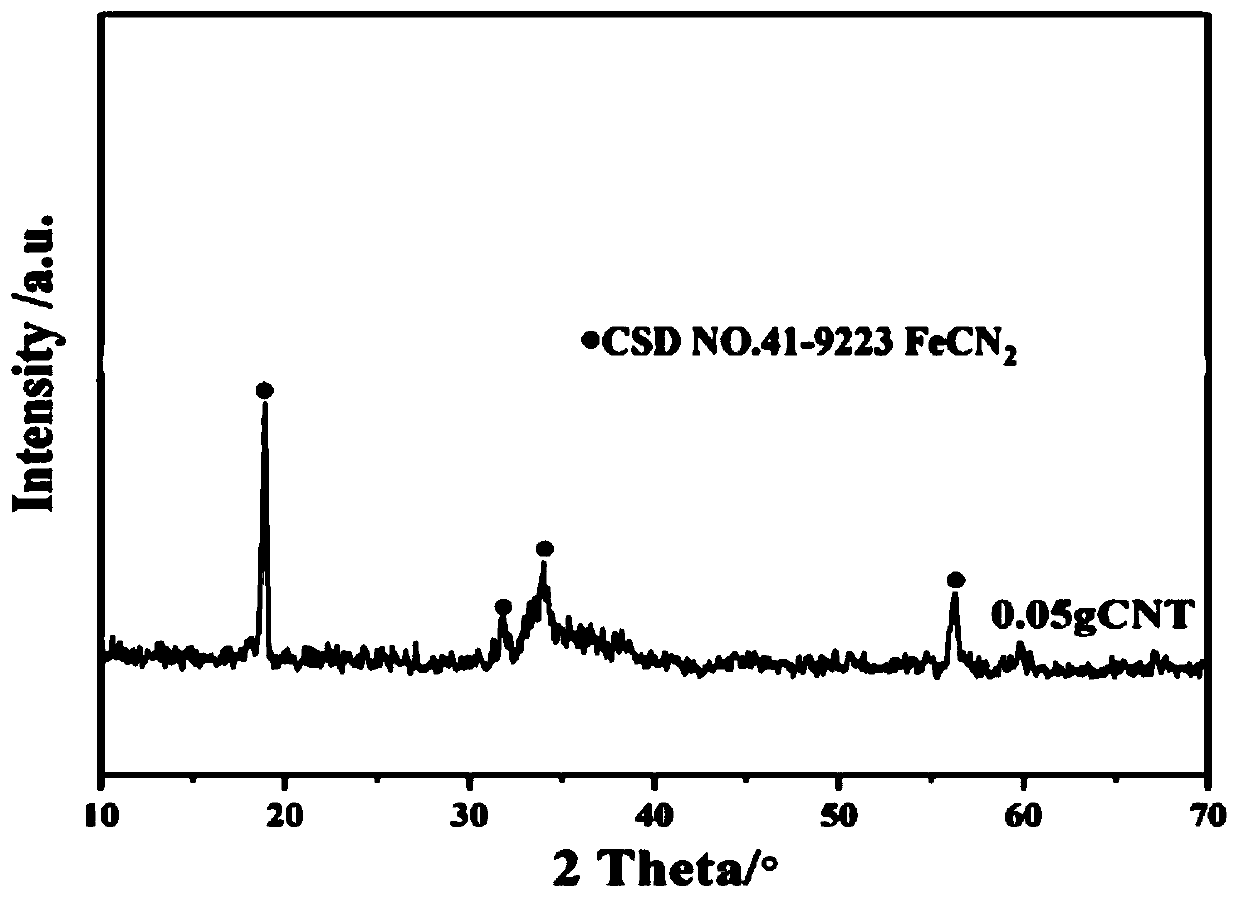

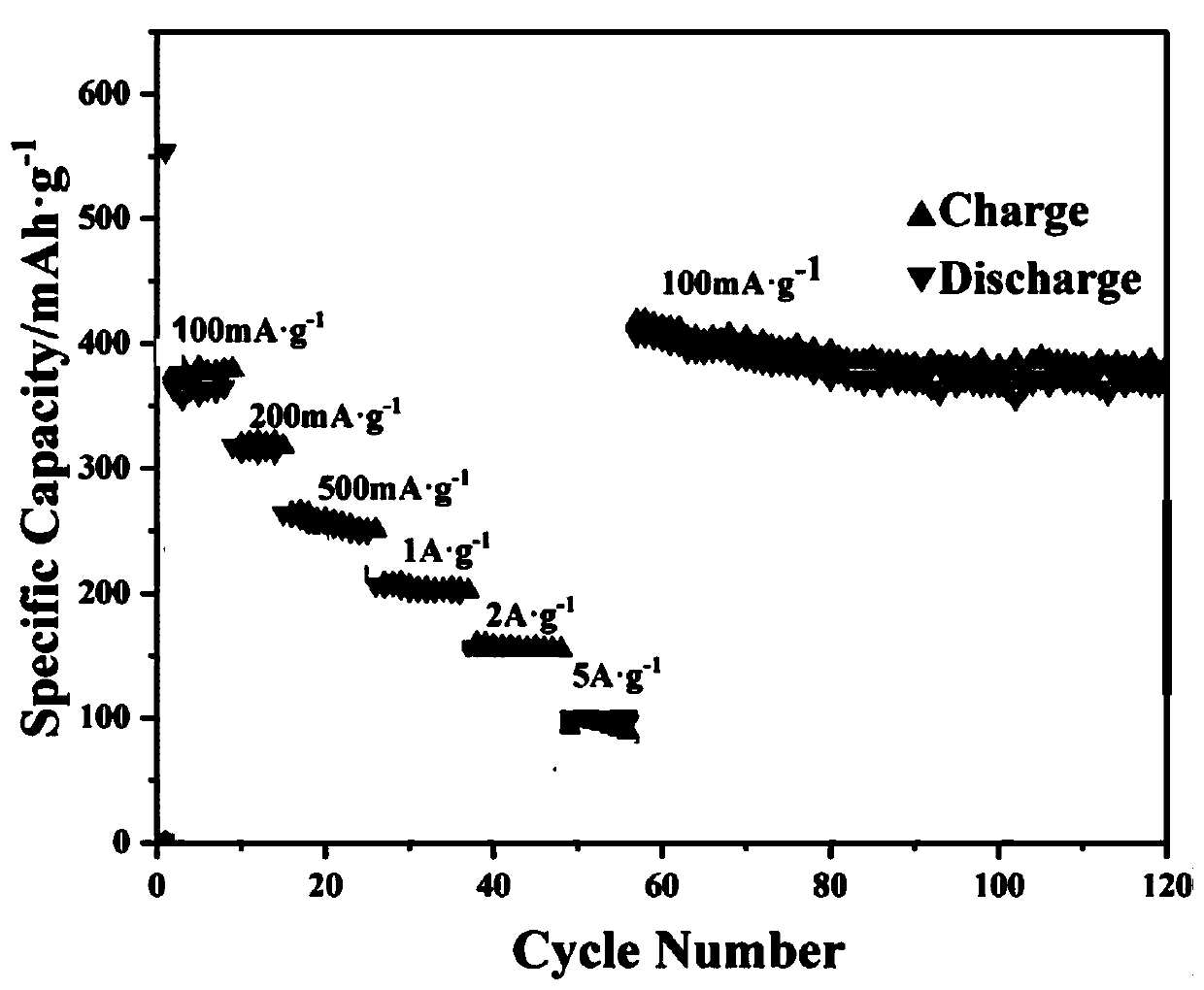

[0025] 3) Put the product B in a ceramic crucible and in a tube furnace, pyrolyze it under an argon atmosphere, raise the temperature from room temperature to 160°C at a rate of 30°C / min, keep it for 1h, and then continue to heat it at 5°C The heating rate of / min continues to rise to 400 ° C, and the obtained product is a carbon-based composite iron cyanamide m...

Embodiment 2

[0028] Prepare carbon-based composite ferric cyanamide material according to the following steps:

[0029] 1) Take 1.5g of analytically pure ferricamine oxalate, 3g of urea, and 0.45g of graphene respectively according to the mass ratio of 1:2:0.3, and place them in a glass mortar for full grinding to obtain a fine and uniform light green mixture powder, the product mark it as A;

[0030] 2) Add 0.045g of ethanolamine to product A, dissolve it in water, disperse it ultrasonically for 30min, put it into a freeze dryer, and dry it at -50°C for 16h to obtain a completely dry black product, which is marked as B;

[0031] 3) Put the product B in a ceramic crucible and in a tube furnace, pyrolyze it under an argon atmosphere, raise the temperature from room temperature to 160°C at a rate of 30°C / min, keep it warm for 1h, and then continue to heat it at 6°C The heating rate of / min continues to rise to 600 ° C, and the obtained product is a carbon-based composite iron cyanamide mate...

Embodiment 3

[0034] Prepare carbon-based composite ferric cyanamide material according to the following steps:

[0035] 1) Take 2g of analytically pure ferricamine oxalate, 4g of urea and 0.12g of super-p respectively according to the mass ratio of 1:2:0.6, put them in a glass mortar and grind them thoroughly to obtain a fine and uniform light green mixture powder, The product is marked as A;

[0036] 2) Add 0.08g of oleic acid to product A, dissolve it in water, disperse it ultrasonically for 60min, put it into a freeze dryer, and dry it at -50°C for 18h to obtain a completely dried black product, which is marked as B;

[0037] 3) Put the product B in a ceramic crucible and put them together in a tube furnace, pyrolyze it under an argon atmosphere, raise the temperature from room temperature to 160°C at a rate of 30°C / min, and keep it warm for 1h, and then continue to heat it up for 8 The heating rate of °C / min continues to rise to 600 °C, and the obtained product is a carbon-based compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com