Elastic pipe bundle vibration reinforced heat exchange solar cavity heat absorber

A technology of tube bundle vibration and enhanced heat exchange, applied in the direction of solar collectors, components of solar collectors, solar thermal energy, etc. The problems of high focused energy density on the tube surface and limited flow heat transfer capacity in the tube can improve safety and heat transfer performance, improve flow heat transfer performance, and improve working life and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

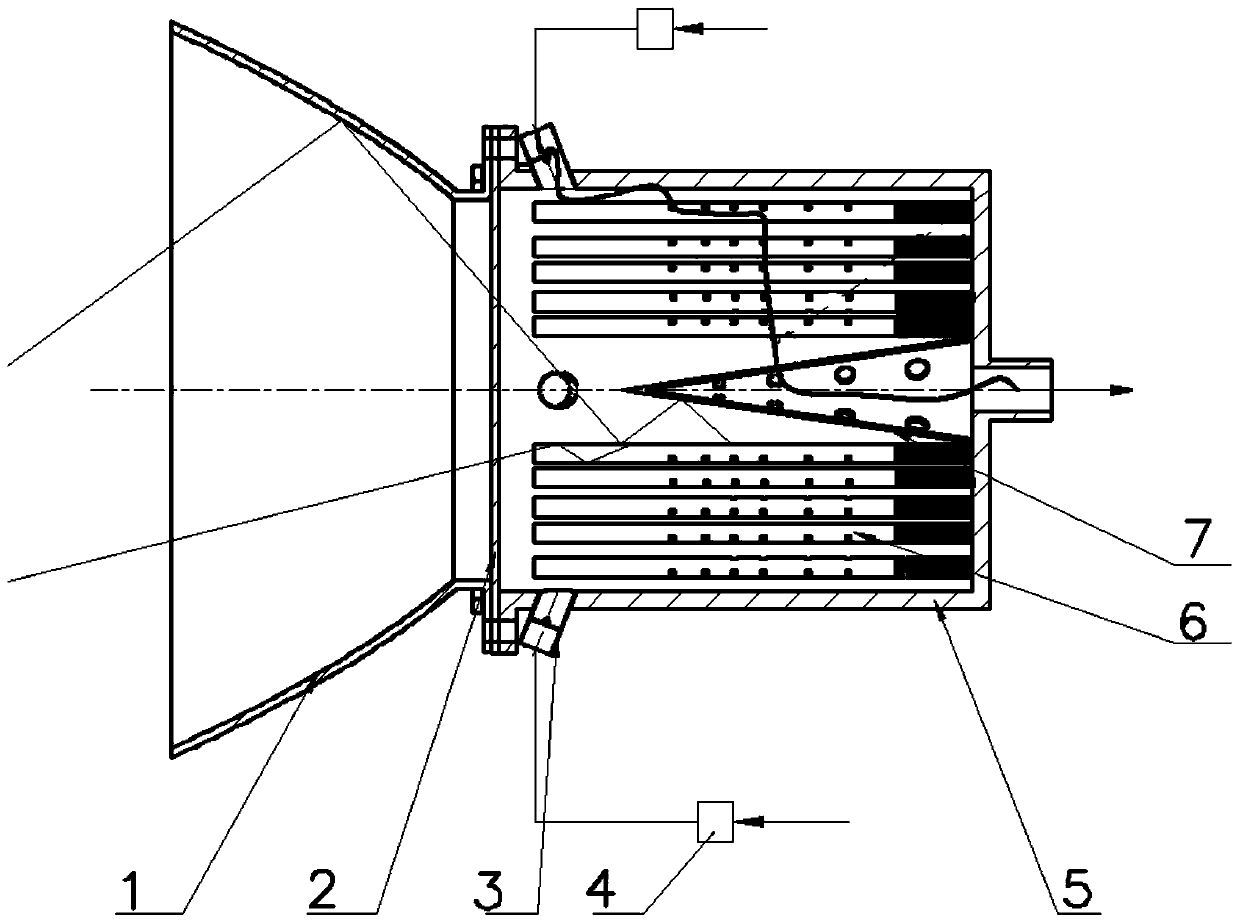

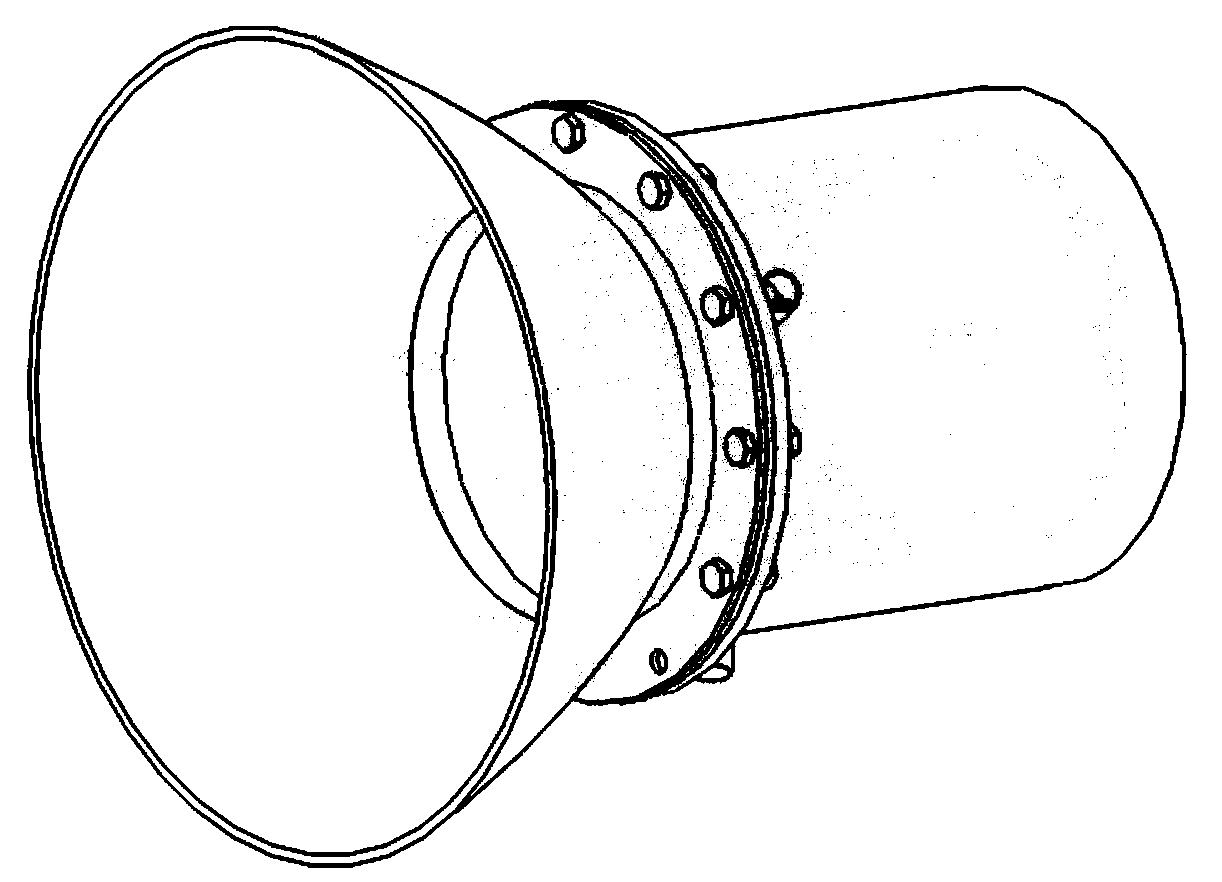

[0032] like figure 1 As shown, Embodiment 1 of the present invention includes a secondary concentrator 1 , a glass plate 2 , a pulsating flow generator 3 , a metal cavity 5 , an elastic tube bundle 6 , a deflector 7 and an on-off valve 4 . The metal cavity 5 is a cylindrical structure, or a cylindrical structure with a quadrangular, triangular, or elliptical cross-section, and a flange is provided at the front end. The secondary concentrator 1 and the glass plate 2 are installed at the front opening of the metal cavity 5 through a flange, the glass plate 2 is located between the secondary concentrator 1 and the metal cavity 5, and the secondary concentrator 1 is used In order to continue to gather the received solar energy into the heat absorber, the cross-section of the inner surface of the secondary concentrator 1 is parabolic, and the inner surface is a specular reflective wall.

[0033] The bottom of the metal cavity 5 is provided with a through hole. like figure 2 As ...

Embodiment 2

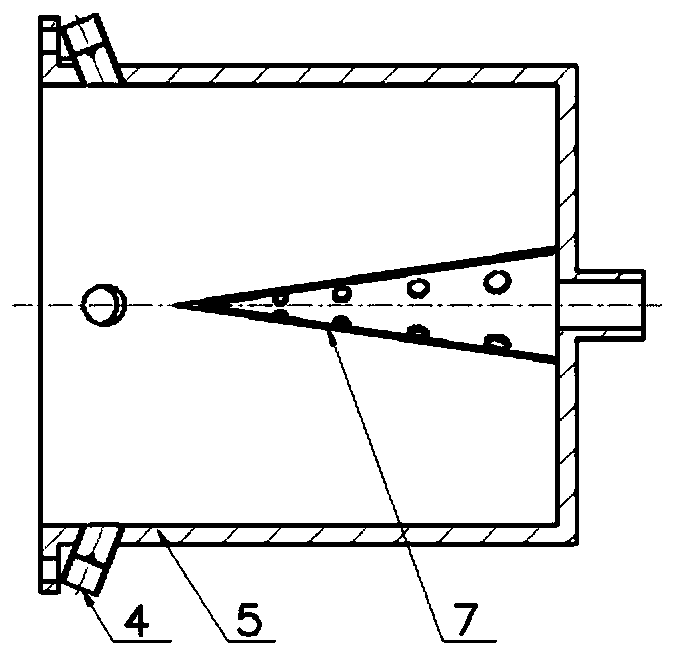

[0038] like Figure 6 As shown, the structure of Embodiment 2 of the present invention is similar to that of Embodiment 1, mainly that the internal structure of the deflector 7 and the metal cavity 5 is different from that of Embodiment 1. details as follows:

[0039] like Figure 6 As shown, the deflector 7 is a hollow cylindrical structure, the end of the deflector 7 is concave tapered, and a number of through holes are provided on the side wall of the deflector 7 . The deflector 7 is fixed on the bottom of the metal cavity 5 by welding, and the inner cavity of the deflector 7 communicates with the through hole at the bottom of the metal cavity 5 .

[0040] like Figure 7 , 8 As shown, the metal cavity 5 is provided with a plurality of partitions 12; the partitions 12 are sequentially connected to the bottom of the metal cavity 5, the inner wall surface and the outer wall surface of the deflector 7, the described The height of the deflector 7 and the partition plate 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com