A multi-effect rapid baking preheating device for alloy material and its application method

A preheating device and alloy technology, applied in the field of smelting, can solve the problems of high requirements for flue gas dust removal devices, unguaranteed quality of molten steel, and low heat exchange efficiency of flue gas, and achieve low equipment material requirements, improve heat utilization efficiency, The effect of complete security measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

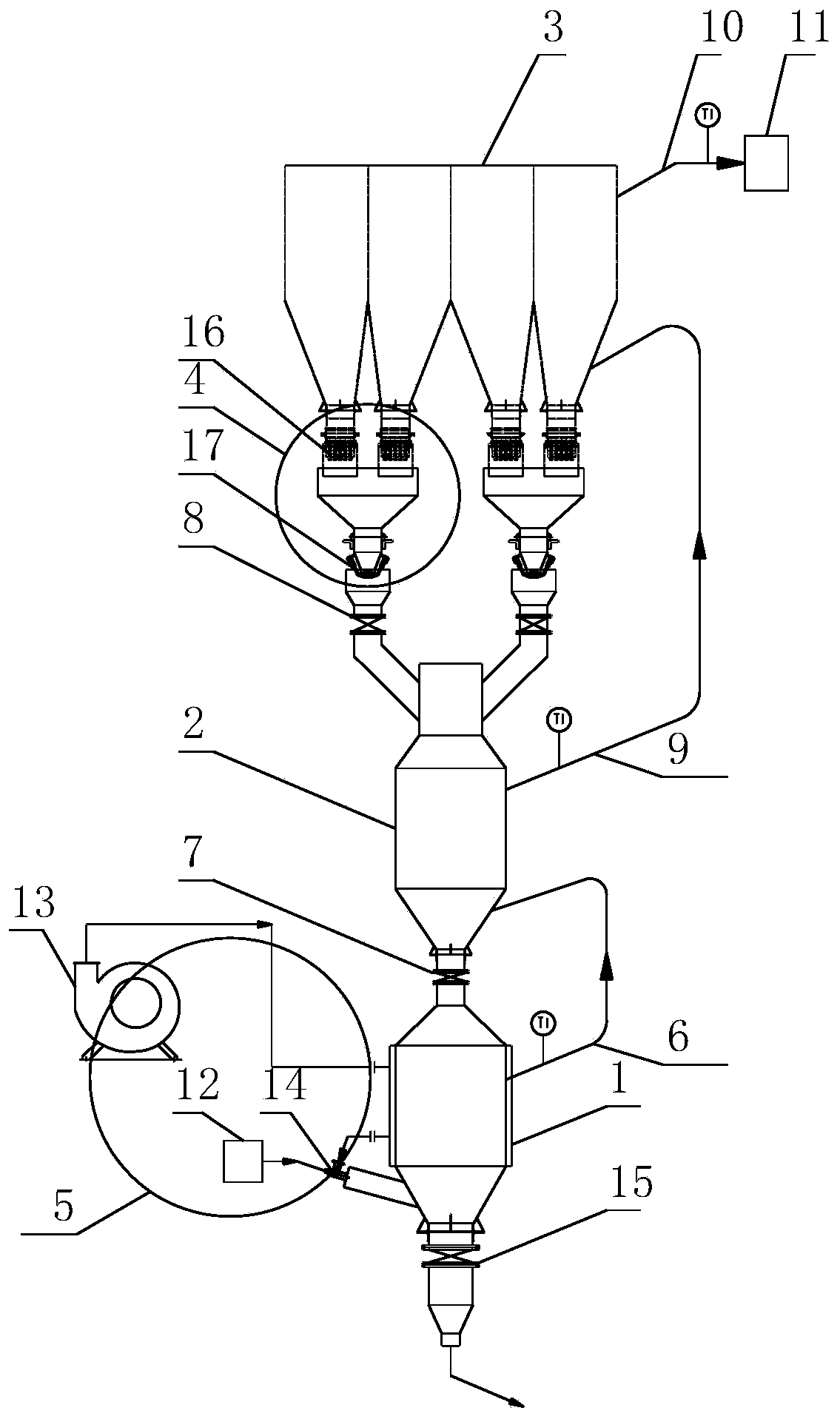

[0032] Attached below figure 1 The multi-effect fast baking and preheating device for alloy material of the present invention and its application method are described in detail.

[0033] A multi-effect rapid baking and preheating device for alloy materials, the device includes a heating bin 1, a stock bin 2, and several main bins 3 arranged in pairs, which are sequentially arranged from bottom to top. Material system 4, combustion system 5 and automatic control system; Wherein,

[0034] The heating bin is provided with a first flue gas discharge pipe 6 and a first alloy lump conveying pipe connected with the stock preparation bin, and a first gate opening and closing valve is arranged on the first alloy lump conveying pipe 7. The first flue gas discharge pipe is arranged on the upper side wall of the heating chamber; the combustion system is arranged in the bottom combustion chamber of the heating chamber, and the high-temperature flue gas generated in the bottom combustion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com