A kind of modified clinoptilolite and its preparation method and application

A clinoptilolite and modification technology, which is applied in the field of modified clinoptilolite and its preparation, can solve the problems of many influencing factors, missing the best time, and the decline of effect of promotion and absorption absorption, so as to increase specific surface area, increase Na+ exchange amount, effect of improving alkali modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 modified clinoptilolite

[0042] The natural clinoptilolite (origin: Chaoyang, Liaoning) was pulverized and washed with pure water until there was no suspended powder, rinsed twice with water, and dried at 120°C to obtain the original ore sample. Weigh 30 g of clinoptilolite raw ore sample, heat it in a muffle furnace at 450 °C for 4 hours, cool it naturally, add it to 300 mL of 2 mol / L NaOH solution, stir and heat it at 80 °C for 24 hours, remove the supernatant, Rinse repeatedly with pure water until neutral, dry at 120°C for 2 hours, screen with a 400-mesh sieve, and store in a sealed container.

Embodiment 2

[0043] Example 2 Characterization of modified clinoptilolite

[0044] The modified clinoptilolite prepared in Example 1 was detected as follows:

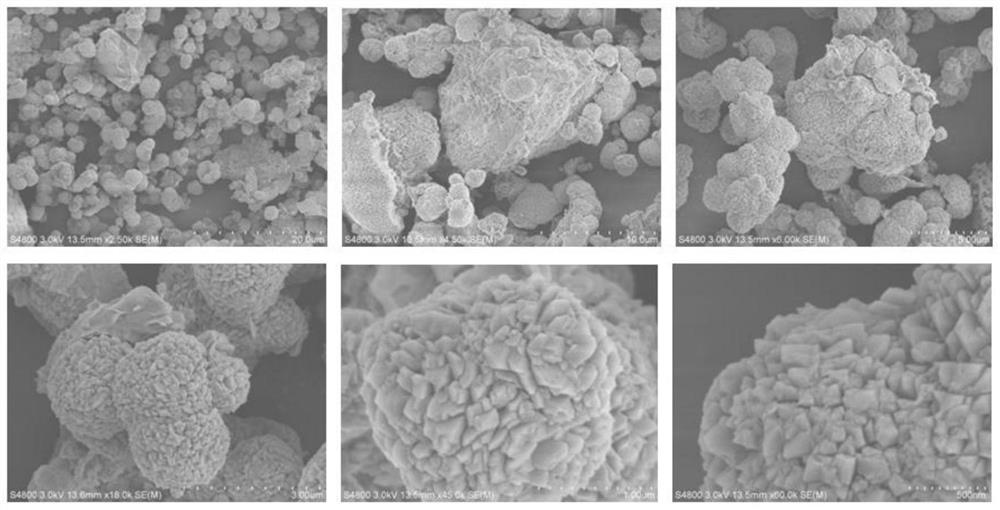

[0045] In order to observe the microstructure of modified clinoptilolite, the scanning electron microscope was used to observe, and the results are as follows figure 1 As shown, it can be seen that the clinoptilolite has a porous structure.

[0046] The chemical analysis results of the modified clinoptilolite minerals are shown in Table 1. It can be seen from Table 1 that the ratio of silicon to aluminum in the modified clinoptilolite is n(Si / Al)=2.79, the Na content is higher than 4 wt%, and the Ca content is higher than 3.5 wt%.

[0047] Table 1 Chemical composition of modified clinoptilolite

[0048] composition Content (wt%) SiO 2

59.5061 Al 2 O 3

21.3511 CaO 5.8771 Na 2 O

5.4460 Fe 2 O 3

3.8495 K 2 O

1.7465 MgO 0.8628 SrO 0.8024 TiO 2 ...

Embodiment 3

[0054] Example 3 The saturated adsorption capacity of modified clinoptilolite to nuclides in aqueous solution

[0055] Take by weighing the modified clinoptilolite and natural clinoptilolite (origin: Chaoyang, Liaoning, with embodiment 1) prepared by 0.1g embodiment 1 respectively, by solid-liquid ratio 1:200, add to the Mn that concentration is 1000mg / L respectively 2+ , Ni 2+ , Co 2+ , Sr 2+ and Cs + In the water sample, placed in a constant temperature shaker, at 30 °C, static adsorption was carried out for different times, the sample was centrifuged at 5000 rpm, the supernatant was taken, and Mn was detected by ICP 2+ , Ni 2+ , Co 2+ , Sr 2+ and Cs + concentration, and calculate the adsorption capacity of clinoptilolite according to formula (1).

[0056] q=V(C 0 -C t ) / m (1)

[0057] In the formula: q—adsorption capacity, mg / g;

[0058] m—mass of modified zeolite, g;

[0059] C 0 —Initial ion mass concentration, mg / L;

[0060] C t - mass concentration of re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com