Preparation method of wrinkle gloves

A glove and wrinkle technology, which is applied in the field of glove preparation, can solve the problems of non-environmental protection, easy wrinkling, wear resistance and unsatisfactory use, and achieve corrosion-resistant grip performance, improved grip performance, and excellent grip performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

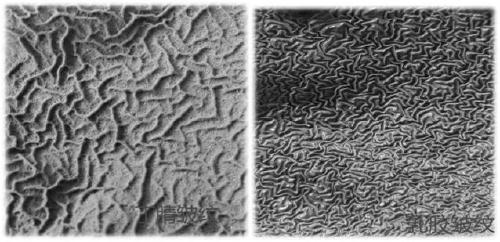

Image

Examples

Embodiment 1

[0035] The present embodiment provides a preparation method of natural latex wrinkled gloves, comprising the steps of:

[0036] Step S1: adding 1.2 parts of sodium polyacrylate to 100 parts by weight of pre-vulcanized natural latex to obtain a dope with a viscosity of 3000 mPa.s.

[0037]Step S2: Immerse the 13-needle polyester knitted glove embryo in a 2% calcium nitrate methanol solution at a temperature of 50° C. After immersing the solid agent, immerse it in the glue prepared in step S1, take it out, and spray it with powder The device sprays casein on the surface of the glove embryo, the spraying time is 10s, and is concentrated on the fingers and the palm of the palm surface of the glove.

[0038] Step S3: pre-vulcanization and drying at 70° C. for 40 minutes, and then rinsed with water.

[0039] Step S4: first vulcanizing and drying at 75°C for 40 minutes, then vulcanizing and drying at 110°C for 70 minutes, after the drying is completed, the gloves are taken out of th...

Embodiment 2

[0041] The present embodiment provides a preparation method of nitrile wrinkled gloves, which comprises the steps:

[0042] Step S1: adding 0.8 part of casein to 100 parts by weight of pre-vulcanized nitrile latex to obtain a dope with a viscosity of 3500 mPa.s.

[0043] Step S2: Preheat the flannel glove embryo to 30°C, immerse it in the glue prepared in step S1, and after taking it out, use a powder sprayer to spray polyacrylic acid powder on the surface of the glove embryo, the spraying time is 20s, and focus on the palm of the glove. face side.

[0044] Step S3: pre-vulcanization and drying at 75° C. for 40 minutes, and then rinsed with water.

[0045] Step S4: first vulcanizing and drying at 80° C. for 30 minutes, then vulcanizing and drying at 120° C. for 60 minutes, after the drying, the gloves are taken out of the drying box, and the gloves are removed from the hand mold to obtain nitrile wrinkled gloves. The wrinkles on the surface of the glove make the glove non-sl...

Embodiment 3

[0048] The present embodiment provides a preparation method of butyl wrinkle gloves, which comprises the steps:

[0049] Step S1: adding 2.5 parts of 2% CMC to 100 parts by weight of pre-vulcanized butyl latex to obtain a dope with a viscosity of 4000 mPa.s.

[0050] Step S2: Preheat the flannel glove embryo to 30°C, immerse it in the glue prepared in step S1, take it out, use a powder sprayer to spray PVP powder on the surface of the glove embryo, the spraying time is 15s, and focus on the palm surface of the glove side.

[0051] Step S3: pre-vulcanizing and drying at 60° C. for 50 minutes, then washing with water, and the PVP in water can be recovered. Step S4: first vulcanizing and drying at 80° C. for 30 minutes, then vulcanizing and drying at 120° C. for 65 minutes, after the drying, the gloves are taken out of the drying box, and the gloves are removed from the hand mold to obtain butyl wrinkle gloves. The wrinkles on the surface of the glove make the glove non-slip an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com