Active peptide with oil oxidation resisting function, preparation method of active peptide and application of active peptide

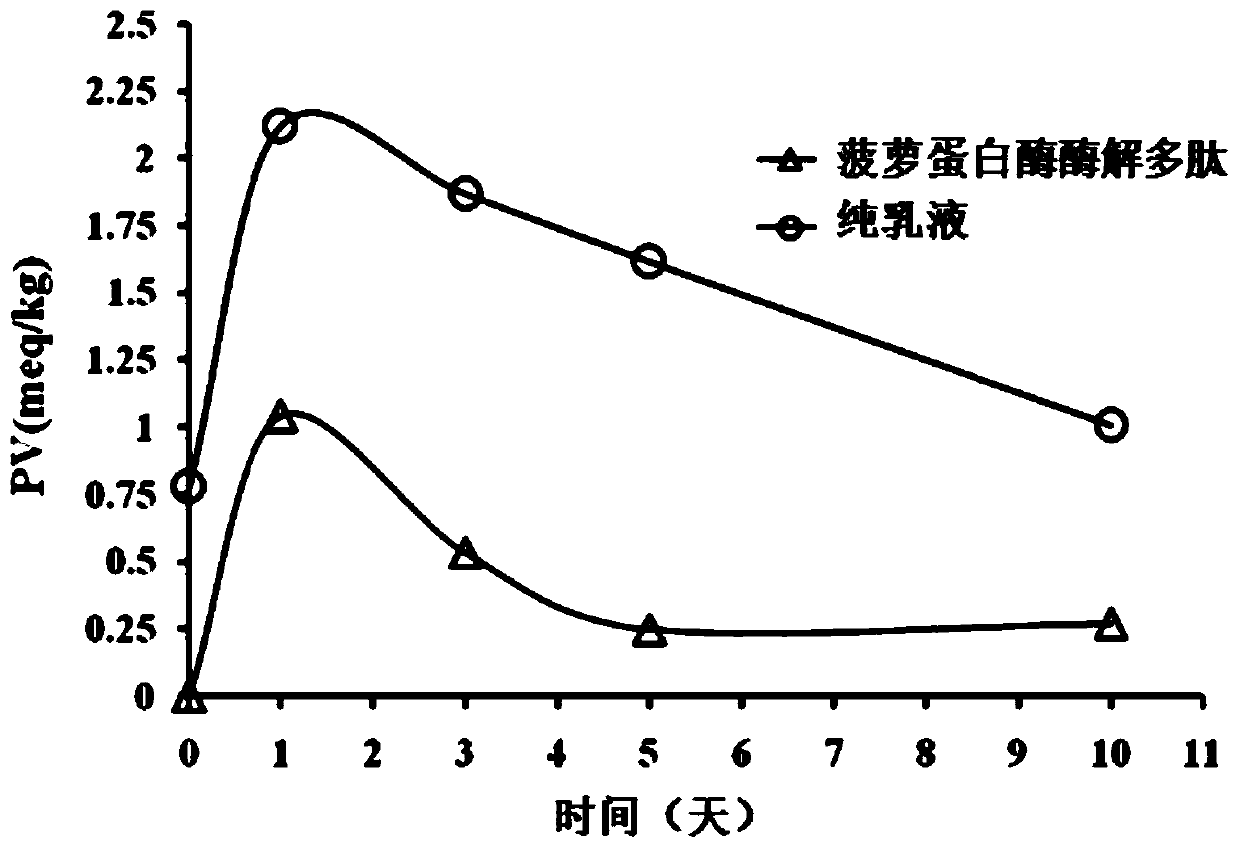

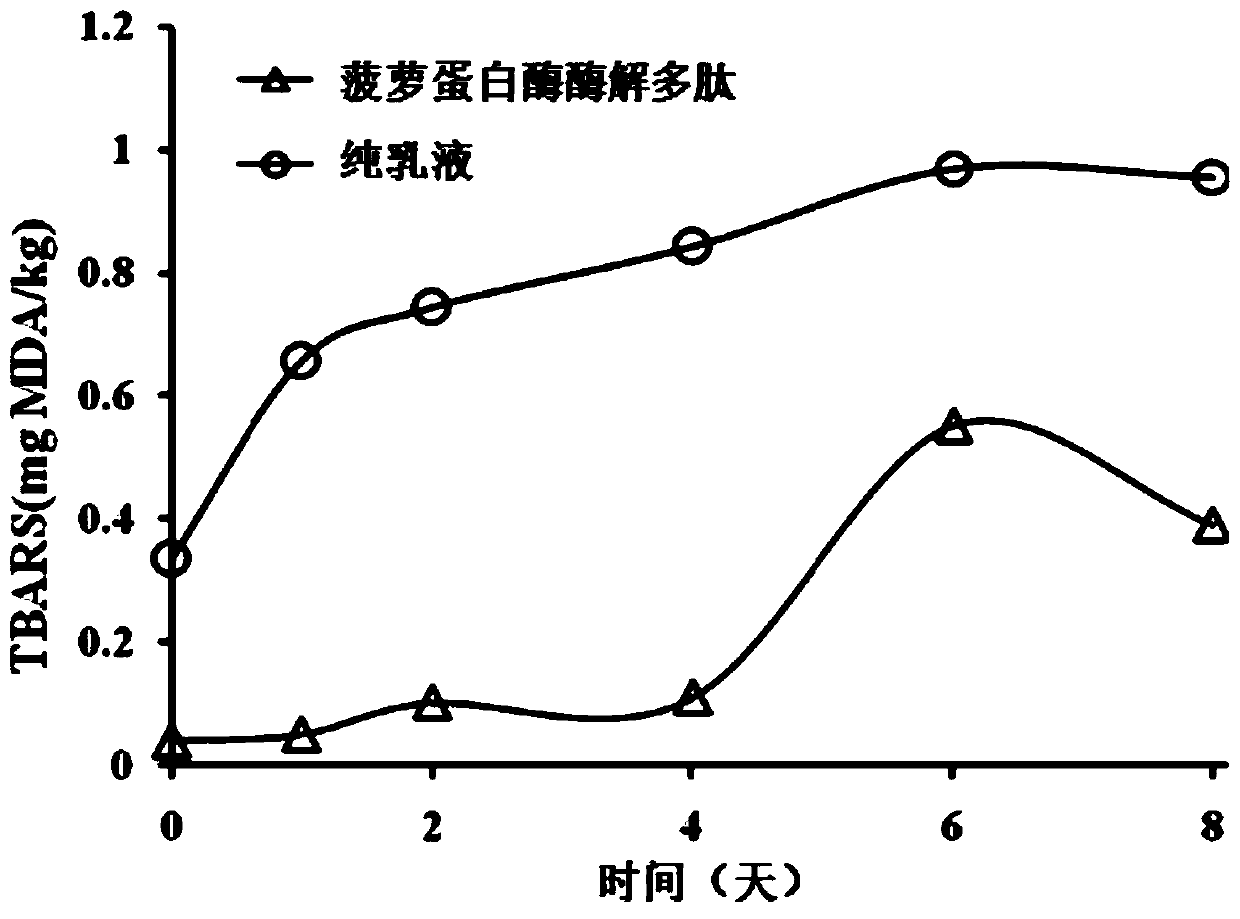

An anti-grease and active peptide technology, which is applied in the field of plant-derived bioactive peptides, can solve the problems of anti-oxidation peptides that cannot resist oxidation of oils, and achieve the effects of prolonging food shelf life, strong activity, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] ②Preparation of serine standard solution: 50mg of serine was dissolved in 500mL of deionized water (0.9516meqv / L);

[0064] ③ Preparation of sample solution: Dilute the enzymatic hydrolysis supernatant 5 to 50 times with deionized water (so that the measured absorbance is between 0.2 and 0.8), and mix well;

[0065] ④Standard measurement: Add 400 μL of serine standard solution into a stoppered test tube containing 3 mL of OPA reagent, shake well, react accurately at room temperature for 2 minutes, and then measure its absorbance at 340 nm with a UV spectrophotometer;

[0066] ⑤ Blank measurement: Add 400 μL deionized water to a stoppered test tube containing 3 mL of OPA reagent, shake well, react accurately at room temperature for 2 minutes, and then measure its absorbance at 340 nm;

[0067] ⑥Sample detection: Add 3 mL of OPA reagent to 400 μL of the sample to be tested and mix well, let it stand at room temperature for 2 minutes, and then measure its absorbance at 340...

Embodiment 1

[0098] Example 1 Preparation of Black Bean Anti-fat Oxidation Peptide AOP1

[0099] Black soybeans are rich in hydrophobic amino acids, and its hydrophobic amino acid ratio is as high as 45%. Peptides containing hydrophobic amino acids are more likely to react with fat-soluble substances, and hydrophobic amino acids increase the solubility of peptides in oil systems, so black soybeans are selected as raw materials .

[0100] (1) Protein extraction: the black soybean powder after oil extraction was resuspended in deionized water at 1:8 (w / v, g / mL, the same below), stirred for 60 minutes, and the pH was adjusted to about 8.0 with 0.015M NaOH, Stir for 2h, centrifuge at 8000rpm for 15min, take the supernatant and adjust to pH 4.5 with 2M HCl, centrifuge at 8000rpm for about 15min to precipitate the protein, resuspend in deionized water and use 0.015MNaOH to adjust the pH back to neutral, and finally freeze-dry Black soybean protein can be obtained;

[0101] (2) Infrared pretrea...

Embodiment 2

[0110] Example 2 Preparation of mung bean anti-lipid oxidation peptide AOP2

[0111] (1) Protein extraction: defatted mung bean powder was resuspended in deionized water at 1:8 (w / v), stirred for 60 minutes, adjusted to about 9.0 with 0.015M NaOH, stirred for 2 hours, centrifuged at 8000rpm for 15 minutes, and taken After clearing, adjust the pH to about 4.0 with 2M HCl, centrifuge at 8000rpm for about 15min to precipitate the protein, resuspend in deionized water, adjust the pH back to neutral with 0.015M NaOH, and finally freeze-dry to obtain mung bean protein;

[0112] (2) Infrared pretreatment: subject the freeze-dried mung bean protein powder to infrared heating treatment at a temperature of 100°C for 20 minutes;

[0113] (3) Proteolysis: Take the protein powder obtained in step (2), add deionized water in a ratio of 1:10 (w / v), shake and mix, adjust the pH of the solution to about 7.0, preheat to 55°C and keep it warm for 10 minutes, Add the selected bromelain (concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com