EVA intermediate membrane for high photopermeability heat insulation interlayer glass and preparation method thereof

A technology of laminated glass and intermediate film, applied in the direction of film/sheet without carrier, non-polymer adhesive additive, adhesive additive, etc., which can solve the problem of low transmittance in the visible light region, general barrier effect, and poor product performance and other problems, to achieve the effect of improving heat insulation performance, uniform strength, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

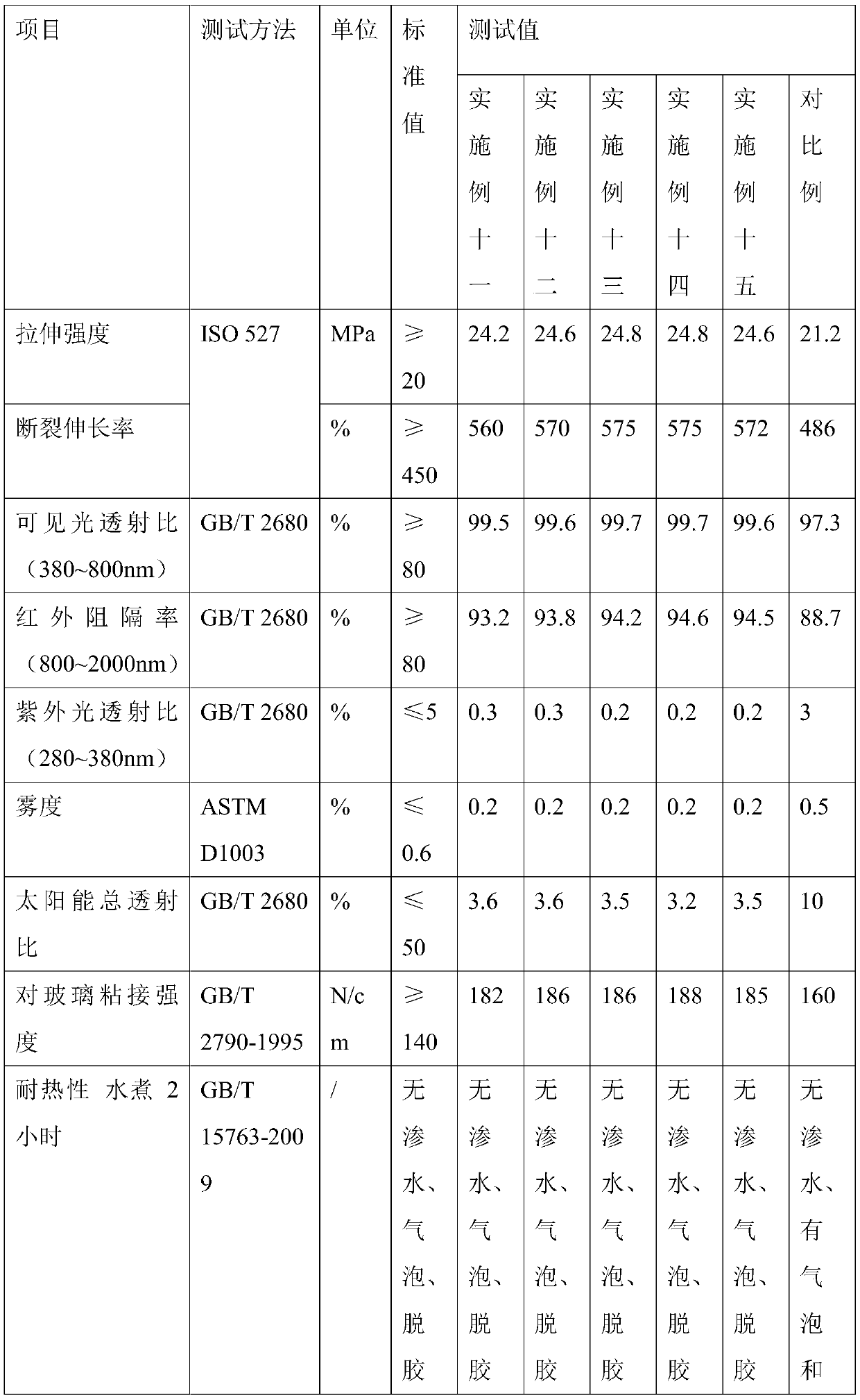

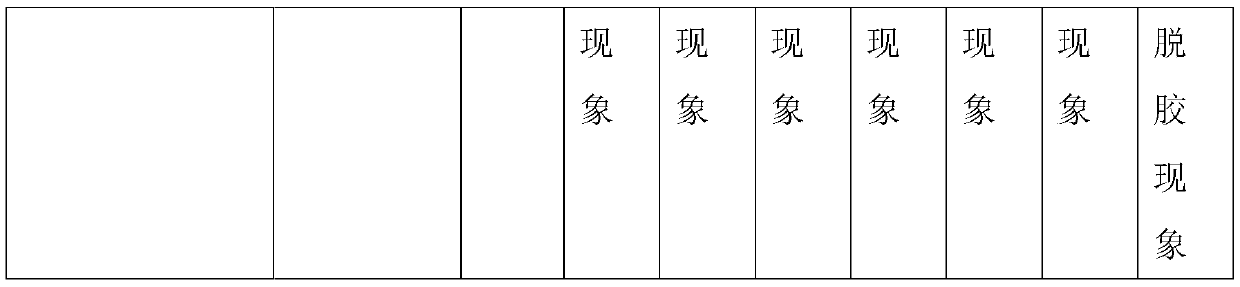

Examples

Embodiment 1

[0045] A kind of EVA master batch, adopts following method to prepare:

[0046] (1) Ingredients: In parts by weight, weigh 70 parts of EVA, 5 parts of light calcium carbonate, 3 parts of chlorinated polyethylene, 1 part of paraffin-calcium stearate, 1 part of white oil softener and α-alkenyl 1 part sodium sulfonate;

[0047] (2) Blend EVA, paraffin-calcium stearate, white oil softener and sodium α-olefin sulfonate to obtain a preform, and the extrusion temperature is 85-100°C;

[0048] (3) Add light calcium carbonate and chlorinated polyethylene into the preform, raise the temperature to 110-120°C, and extrude to granulate.

Embodiment 2

[0050] A kind of EVA masterbatch, the difference with embodiment one is that the formula content of EVA masterbatch is different: by weight, weigh 72 parts of EVA, 6 parts of light calcium carbonate, 3 parts of chlorinated polyethylene, paraffin- 1 part of calcium stearate, 1 part of white oil softener and 1 part of sodium α-alkenyl sulfonate.

Embodiment 3

[0052] A kind of EVA masterbatch, the difference with embodiment one is that the formula content of EVA masterbatch is different: by weight, weigh 75 parts of EVA, 7 parts of light calcium carbonate, 4 parts of chlorinated polyethylene, paraffin- 2 parts of calcium stearate, 2 parts of white oil softener and 2 parts of sodium α-alkenyl sulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com