Three-component fluorescent polymer, preparation method thereof, fluorescence sensor and application of fluorescence sensor

A fluorescent polymer and fluorescent sensor technology, applied in the field of fluorescent sensing, can solve the problems of slow response speed of nitro explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing the three-component fluorescent polymer described in the above technical solution, comprising the following steps:

[0048] Mix boric acid or boric acid ester corresponding to structural unit A, dihalide corresponding to structural unit M, dihalide corresponding to structural unit N, palladium catalyst, potassium carbonate and solvent, and a coupling reaction occurs in a protective atmosphere to obtain three Component fluorescent polymer;

[0049] In the present invention, the structure of the boronic acid corresponding to the structural unit A is shown in formula IV:

[0050]

[0051] The structure of the borate ester corresponding to the structural unit A is shown in formula V:

[0052]

[0053] In the present invention, the structure of the dihalide corresponding to the structural unit M is shown in formula VI:

[0054]

[0055] Said X is preferably chlorine, bromine or iodine.

[0056] In the pre...

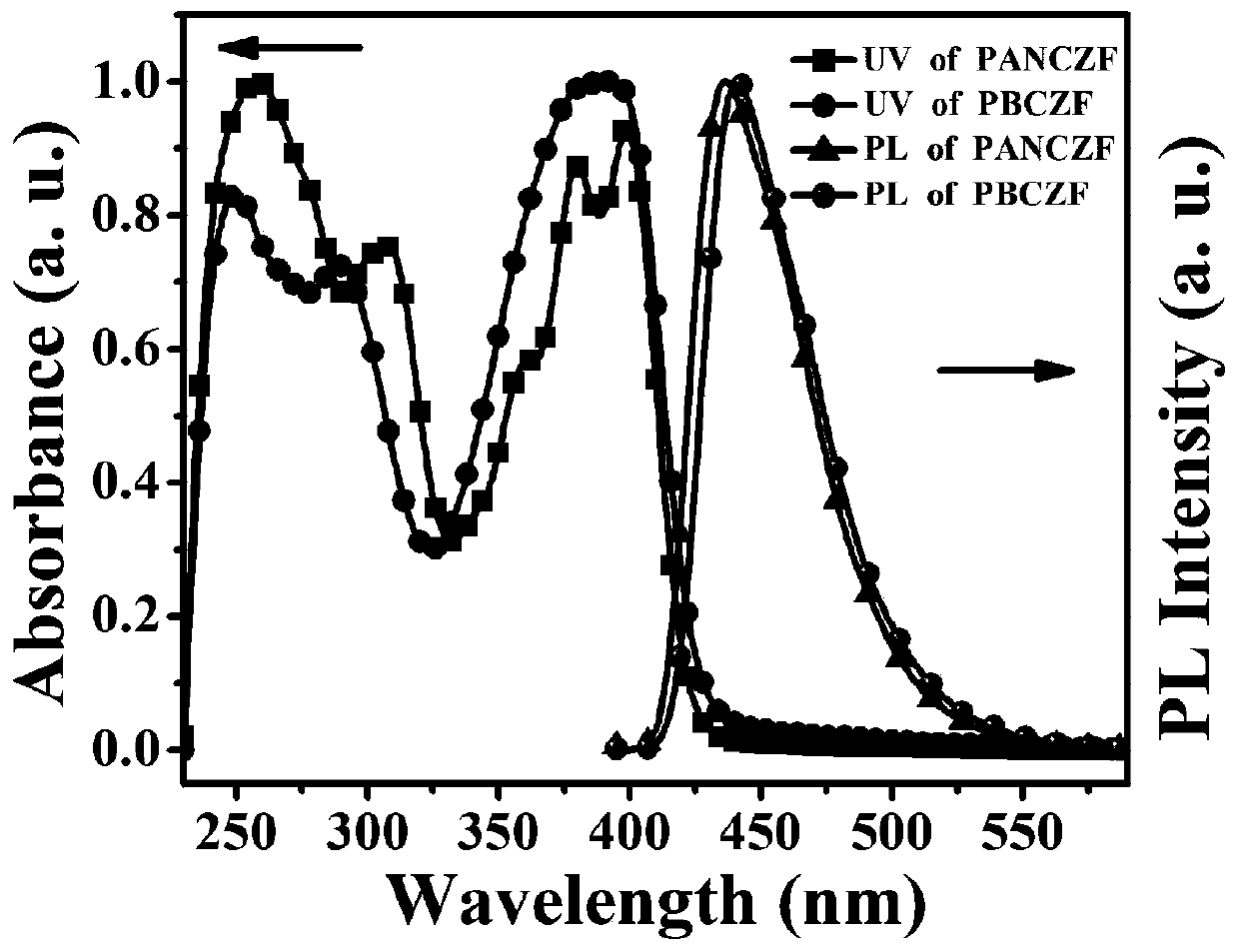

Embodiment 1

[0093] The chemical reaction formula of the present embodiment is as shown in formula (1):

[0094]

[0095] 204.4 mg (0.45 mmol) of 1,6-bis(4,4,5,5-tetramethyl-1,3,2-dioxaboron) pyrene, 74 mg (0.15 mmol) of N-dodecyl- Mix 2,7-dibromocarbazole, 147.6mg (0.3mmol) 9,9-dihexyl-2,7-dibromofluorene, 3mL toluene, 2mL potassium carbonate solution (concentration is 2M) and 1mL absolute ethanol in Under the protection of argon, the raw material mixture was frozen by liquid nitrogen for 8 minutes, then vacuumized for 5 minutes, then 2.3 mg of tetrakis(triphenylphosphine) palladium was added, and the above freezing-vacuumization operation was repeated three times, and the temperature was raised to 100°C and refluxed for 72 hours ; After the reaction was completed, the resulting reaction solution was cooled to room temperature. The reaction solution was added dropwise into 200 mL of methanol, and after filtration, the filtered solid was washed with water and acetone for 18 h, and then...

Embodiment 2

[0102] The chemical reaction formula of the present embodiment is shown in formula (2):

[0103]

[0104]193.6mg (0.45mmol) 9,10-two (4,4,5,5-tetramethyl-1,3,2-dioxaboron) anthracene, 74mg (0.15mmol) N-dodecyl- Mix 2,7-dibromocarbazole, 147.6mg (0.3mmol) 9,9-dihexyl-2,7-dibromofluorene, 3mL toluene, 2mL potassium carbonate solution (concentration is 2M) and 1mL absolute ethanol in Under the protection of argon, the raw material mixture was frozen by liquid nitrogen for 8 minutes, then vacuumized for 5 minutes, 2.3 mg of tetrakis(triphenylphosphine) palladium was added, and the above freezing-vacuumization operation was repeated three times, and the temperature was raised to 100° C. and refluxed for 72 hours; After the reaction was completed, the resulting reaction solution was cooled to room temperature. The reaction solution was added dropwise into 200 mL of methanol, and after filtration, the filtered solid was washed with water and acetone for 18 h, and then the washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com