Molybdenum disulfide, cobalt-modified molybdenum disulfide, pd-loaded nanosheets and their synthesis methods and applications

A technology of molybdenum disulfide and synthesis method, which is applied in the direction of molybdenum sulfide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

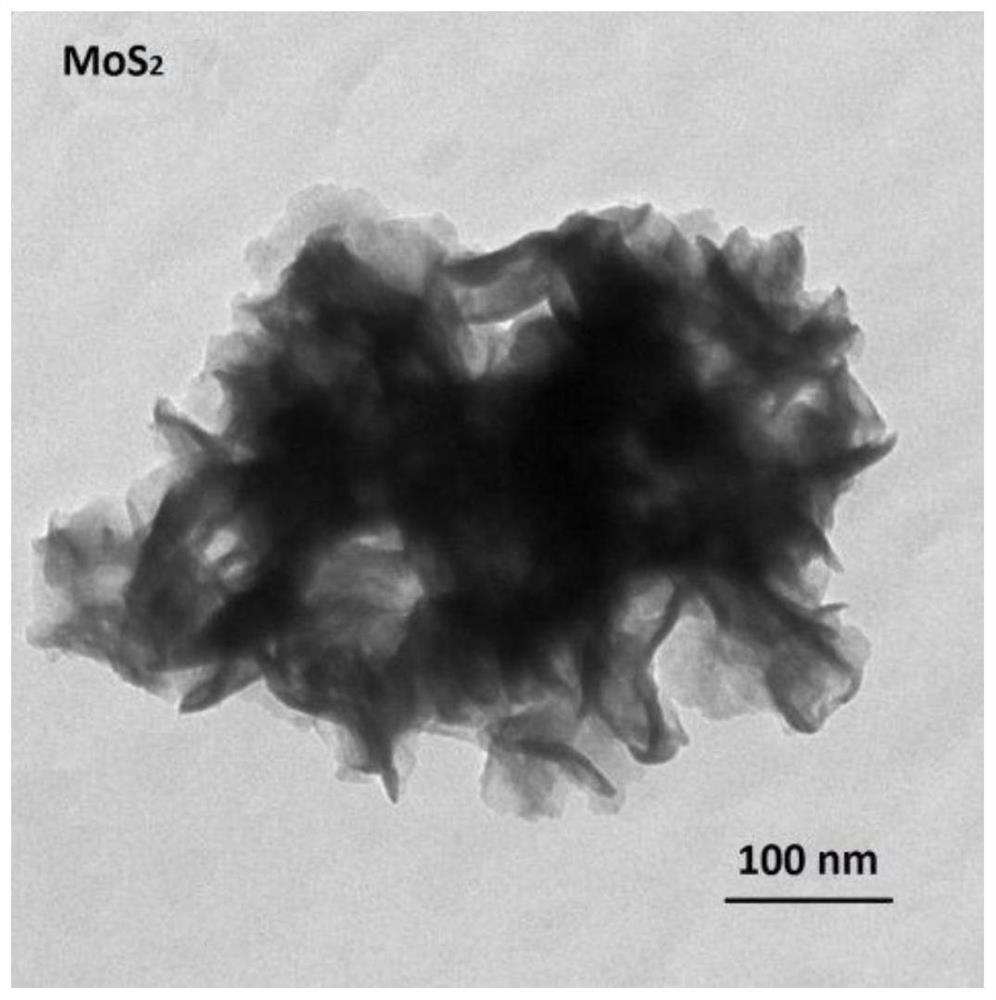

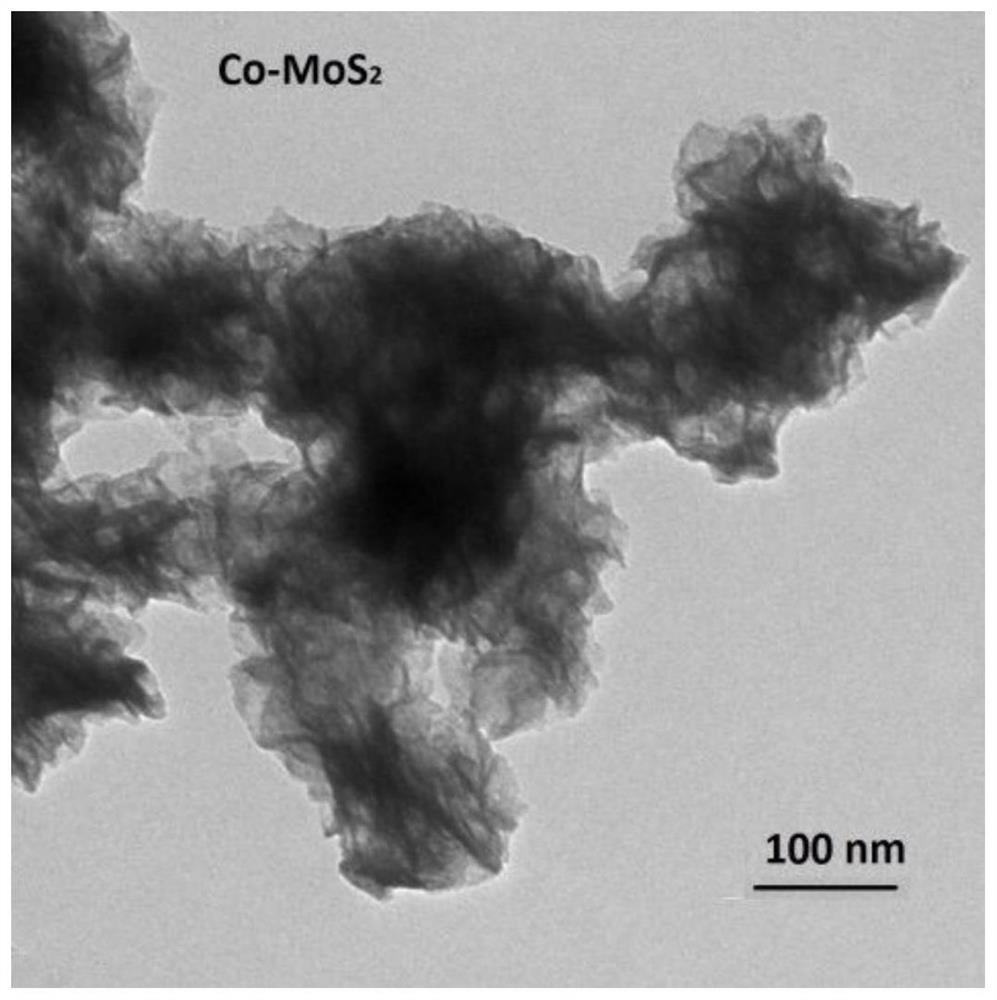

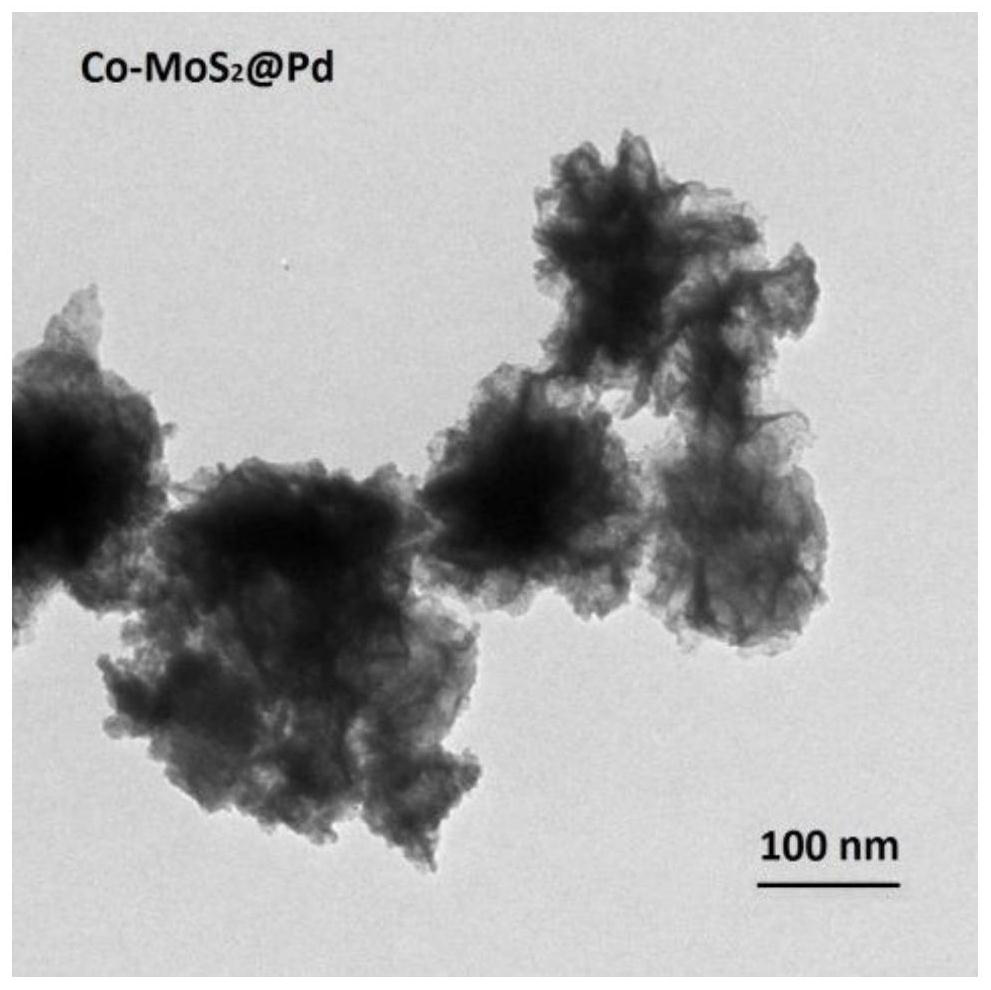

Image

Examples

Embodiment 1

[0049] At room temperature, weigh 0.1210g (0.5mmol) Na 2 MoO 4 .2H 2 O, 0.2284g (3mmol) CS (NH 2 ) 2 powder, and add all the raw materials together into a dry reaction kettle with a capacity of 50mL, and then use a pipette to measure 16mL double-distilled water and 8mL propionic acid into the reaction kettle, and magnetically stir for 10min to obtain a solution. Tighten the reaction kettle and transfer it to an oven, gradually raise the temperature to 180°C, and keep the temperature for 4 hours until the reaction ends. After the reactor is naturally cooled to room temperature, add 0.1455g (0.5mmol) Co(NO 3 ).6H 2 O, magnetically stirred for 30 minutes to obtain a solution, tightened the reaction kettle and transferred it to an oven, gradually raised the temperature to 180° C., and kept the temperature for 4 hours until the reaction was completed. After the reaction kettle was naturally cooled to room temperature, n-heptane and absolute ethanol were added to disperse, the...

Embodiment 2

[0053] MoS 2 、Co-MoS 2 、Co-MoS 2 The electrochemical experiment of loading Pd was carried out on Chenhua CHI660E electrochemical workstation, using a standard three-electrode test system, the corresponding working electrode was the glassy carbon electrode modified by the sample obtained in this example, and the counter electrode was a graphite rod electrode. The reference electrode was silver / silver chloride (Ag / AgCl) (0.1989V vs RHE). All potentials in this example are relative to RHE. All electrochemical tests were performed at 25 °C. In each experiment, all modified electrodes were at N 2 Saturated 0.5mol / L H 2 SO 4 tested in the solution. Before the electrochemical experiment, 10 μL of catalyst dispersion solution (2 mg / mL) was dropped on the glassy carbon electrode, dried, and then 5 μL of 1% naphthol solution was added dropwise to cover the surface of the catalyst, and dried for later use. Test results such as Figure 9 As shown, MoS 2 After the nanocrystals ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com