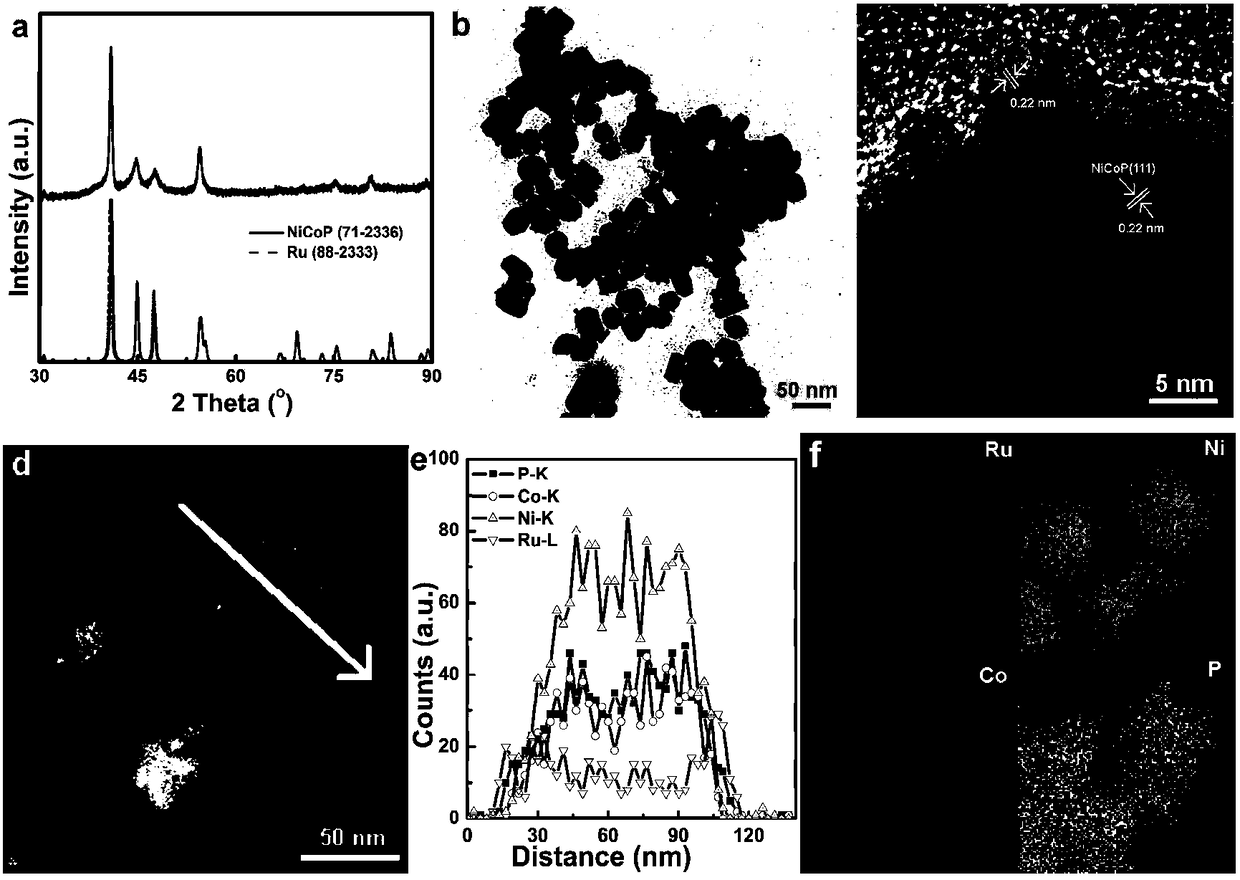

A kind of Ru modified conip nanocrystal and its preparation method and application

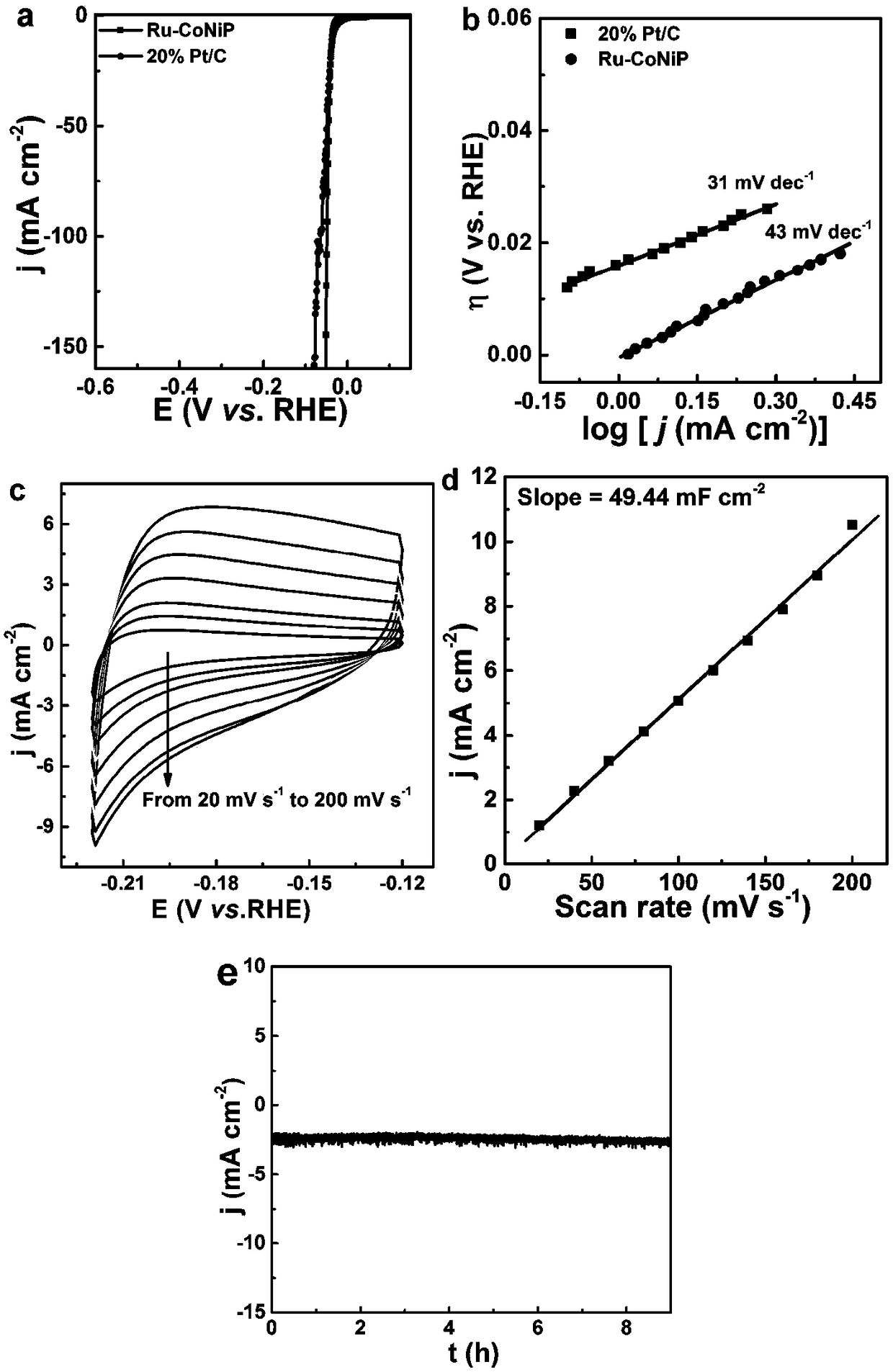

A nanocrystalline and nanotechnology, applied in the field of nanometers, can solve the problems of overpotential and low catalytic activity, and achieve excellent HER performance, low reaction temperature and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, weigh 178 mg (0.7 mmol) Co(acac) 2 , 112 mg (0.75 mmol) Ni(HCO 2 ) 2 and 104mg (0.5 mmol) RuCl 3 • xH 2 O powder, and all the raw materials were added into a dry three-necked round-bottomed flask with a capacity of 250 mL, and then 3 mL of DDA, 1.5 mL of OA and 5 mL of TOP were measured with a graduated cylinder, added to the round-bottomed flask, ultrasonicated and Stir until completely dissolved to give a black solution.

[0032] Transfer the round-bottomed flask to a sand bath, heat up to 320 °C at a rate of 7 °C / min under programmed temperature control, keep warm for 30 min, cool to room temperature, continue to heat up to 320 °C at 7 °C / min, and keep warm 30 min to the end of the reaction. After the reactor was naturally cooled to room temperature, an appropriate amount of ethanol was added to disperse, and the solid was separated by centrifugation. The solid was washed to obtain a black product, which was used for analysis and characteri...

Embodiment 2

[0039] At room temperature, weigh 127 mg (0.5 mmol) Co(acac) 2 , 82 mg (0.55 mmol) Ni(HCO 2 ) 2 and 83 mg (0.4 mmol) RuCl 3 • xH 2 O powder, and all the raw materials were added together into a dry three-neck round bottom flask with a capacity of 250 mL, and then 2.5 mL of DDA, 1.5 mL of OA and 3.6 mL of TOP were measured with a graduated cylinder, added to the round bottom flask, ultrasonicated and Stir until completely dissolved to give a black solution.

[0040] Transfer the round-bottomed flask to a sand bath, heat up to 320 °C at a rate of 7 °C / min under programmed temperature control, keep warm for 30 min, cool to room temperature, continue to heat up to 320 °C at 7 °C / min, and keep warm 30 min to the end of the reaction. After the reactor was naturally cooled to room temperature, an appropriate amount of ethanol was added to disperse, and the solid was separated by centrifugation. The solid was washed to give a black product, which was dried overnight in a vacuum ...

Embodiment 3

[0042] At room temperature, weigh 127 mg (0.5 mmol) Co(acac) 2 , 75 mg (0.5 mmol) Ni(HCO 2 ) 2 and 62 mg (0.3 mmol) RuCl 3 • xH 2 O powder, and all the raw materials were added together into a dry three-neck round bottom flask with a capacity of 250 mL, and then 1 mL of DDA, 1 mL of OA and 3 mL of TOP were measured with a graduated cylinder, added to the round bottom flask, ultrasonicated and Stir until completely dissolved to give a black solution.

[0043] Transfer the round-bottomed flask to a sand bath, heat up to 320 °C at a rate of 7 °C / min under programmed temperature control, keep warm for 30 min, cool to room temperature, continue to heat up to 320 °C at 7 °C / min, and keep warm 30 min to the end of the reaction. After the reactor was naturally cooled to room temperature, an appropriate amount of ethanol was added to disperse, and the solid was separated by centrifugation. The solid was washed to give a black product, which was dried overnight in a vacuum oven. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com