Preparation method of a nanopore array structure with an embedded metal ring

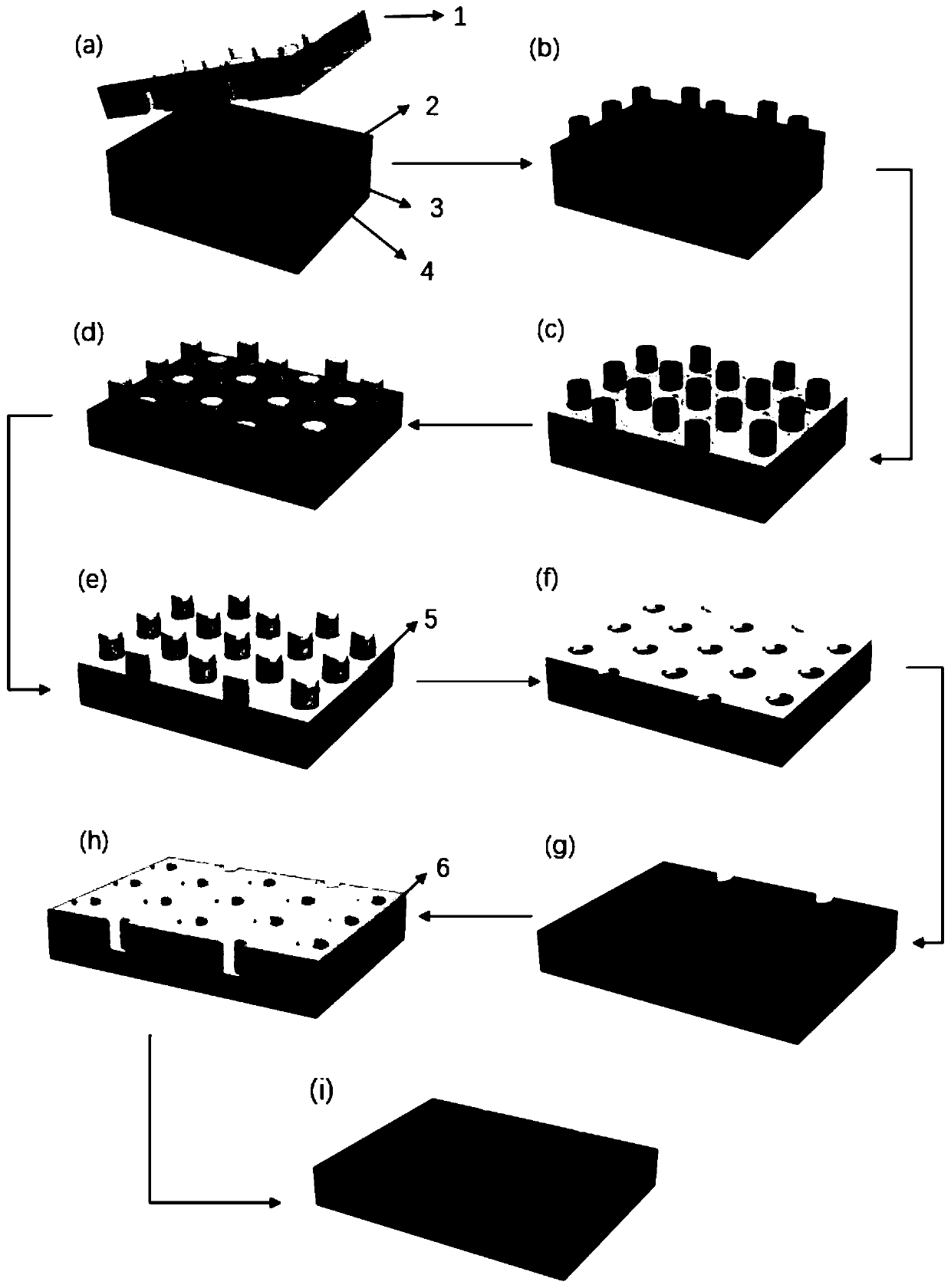

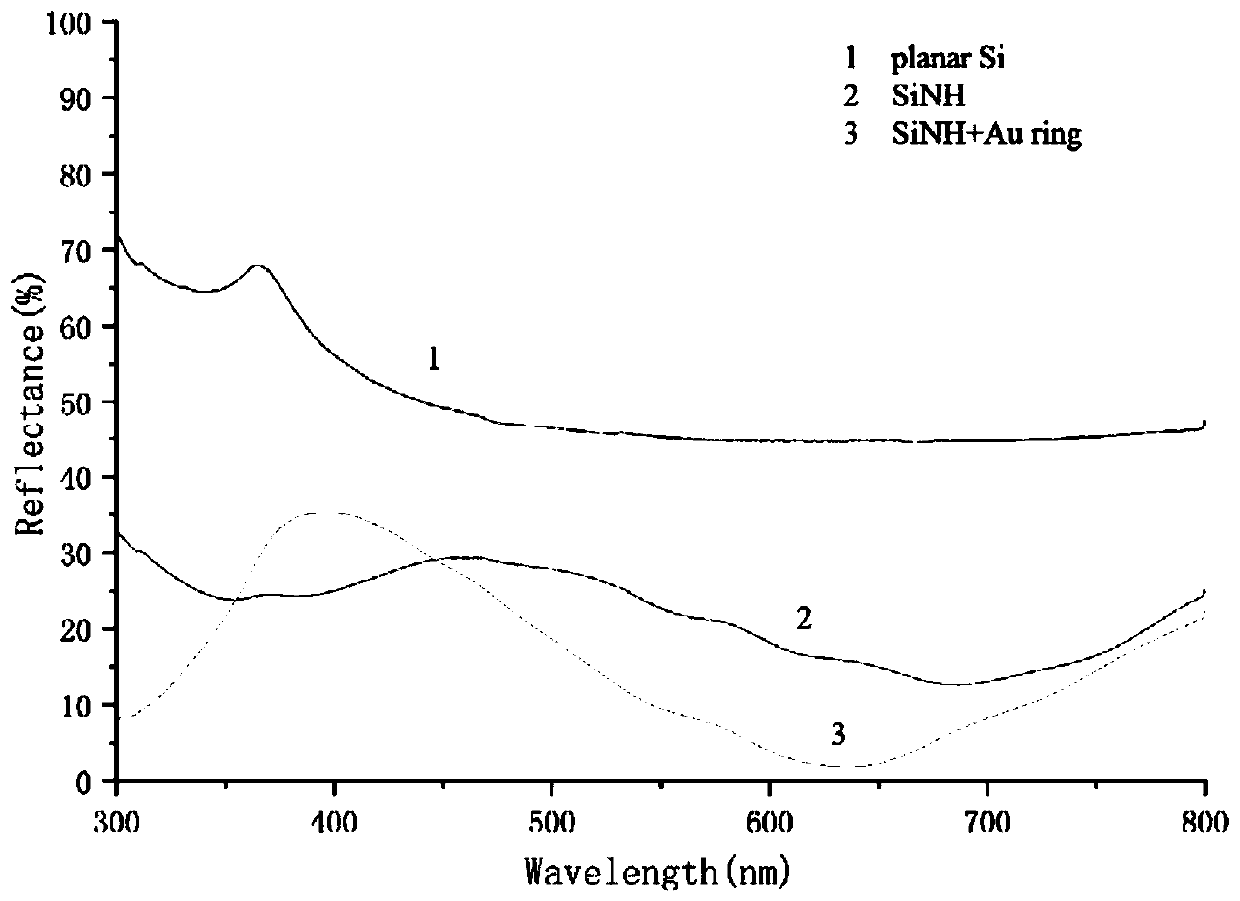

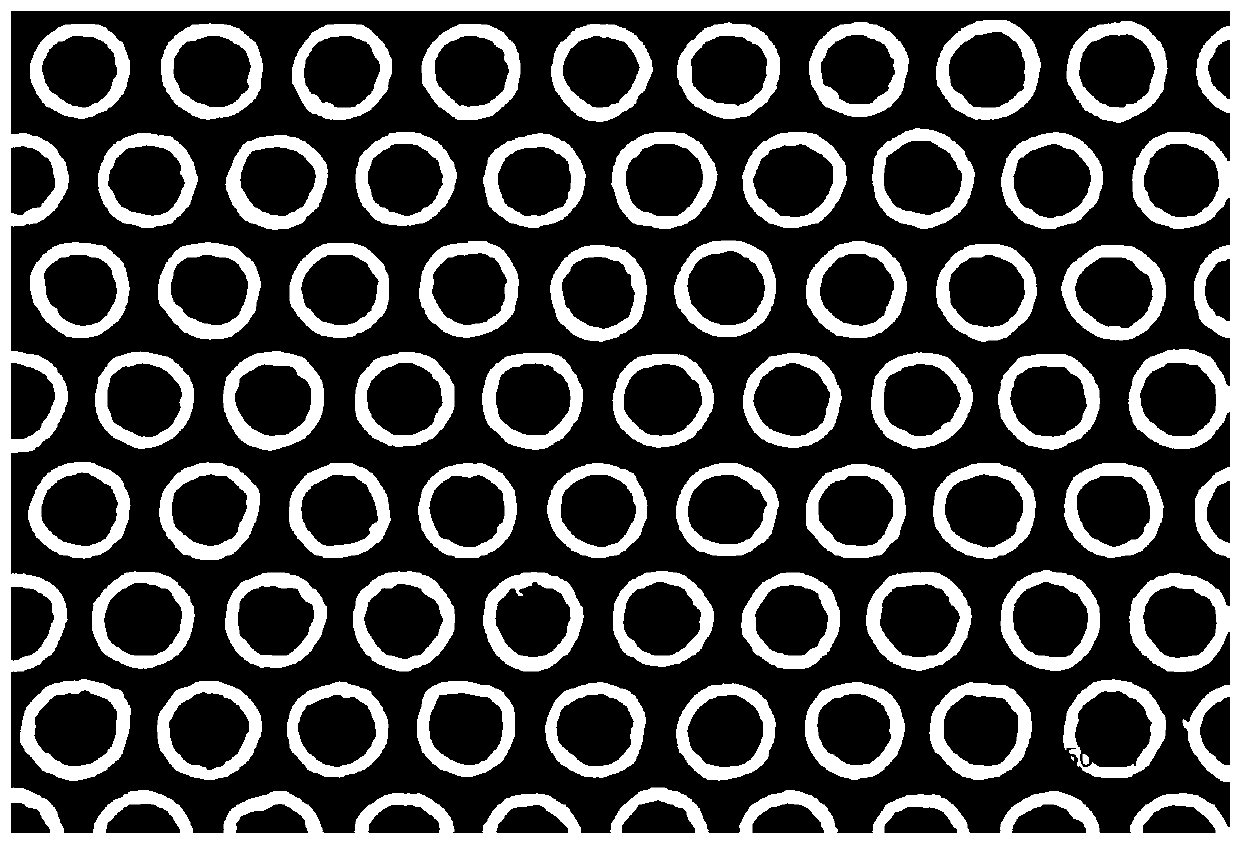

A technology of nano-hole array and nano-pillar array is applied in the field of preparation of nano-hole array structure, which can solve the problems of uncontrollable shape and size distribution of nano-rings, and achieve the effect of increasing the utilization rate of light and improving the conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing a nanohole array structure with an embedded metal ring, specifically as follows:

[0039] Prepare the template: Dow Corning’s 184 Polydimethylsiloxane precursor A component and B component were uniformly mixed at a mass ratio of 10:1, coated on the master template with a nano-pillar array structure, placed in a vacuum drying oven, and pumped Vacuum to 0.5atm, keep the temperature at 85°C, and cure for 5 hours. After the PDMS is peeled off from the template, it will be used as a template for future use. (The master template used is a silicon template with a period of 600nm, a diameter of 400nm, and a hexagonal array of holes; the PDMS template is a pillar array template with the opposite structure to the master template.)

[0040] UV curing embossing: Rinse and clean the polished silicon wafer with deionized water, acetone, and isopropanol in sequence, and dry the surface with a nitrogen gun. Spin-coat a 200nm PMMA layer...

Embodiment 2

[0050] This embodiment provides a method for preparing a nanohole array structure with an embedded metal ring, specifically as follows:

[0051] Prepare the template: use the thermal nanoimprinting technique to imprint the polypropylene film using the nickel template as the master template to obtain a polypropylene template with the opposite structure for future use. (The master template used is a nickel template with a period of 500nm, a diameter of 300nm, and a hexagonal distribution of holes)

[0052] UV curing embossing: Rinse and clean the polished silicon wafer with deionized water, acetone, and isopropanol in sequence, and dry the surface with a nitrogen gun. Spin-coat a 100nm PVP layer on the silicon wafer, and then spin-coat an 80nm UV-curable adhesive layer; then cover the PP template on the UV adhesive layer, place the sample in a nitrogen-filled environment for UV exposure, and take it out after 10 minutes. The PP template was removed to obtain a nanopillar array ...

Embodiment 3

[0060] This embodiment provides a method for preparing a nanohole array structure with an embedded metal ring, specifically as follows:

[0061] UV curing imprinting: Rinse and clean the polished quartz plate with deionized water, acetone, and isopropanol in sequence, and dry the surface with a nitrogen gun. Spin-coat a 200nm PMMA layer on the quartz sheet, and then spin-coat a 100nm UV-curable adhesive layer; then cover the PDMS soft template on the UV adhesive layer, place the sample in a nitrogen-filled environment for UV exposure, and take it out after 10 minutes. The PDMS soft template is removed to obtain a nano-column array structure; the parameters of the PDMS template: the period is 600nm, and the diameter is 400nm.

[0062] Etching the UV-curable adhesive layer and PMMA layer: Calculate the thickness of the imprinted PMMA layer and UV adhesive layer through the structural parameters of the master template, and use ICP to etch the cured UV adhesive layer with an etchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com