X-shaped spoof surface plasmon waveguide with compact structure

A plasma and artificial surface technology, applied in the direction of waveguide, waveguide-type devices, circuits, etc., can solve the problems of reducing the size of waveguide structural units, increasing the waveguide bandwidth transmission surface wave confinement ability, etc., to achieve momentum matching and simple excitation methods Efficient, Small Size Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

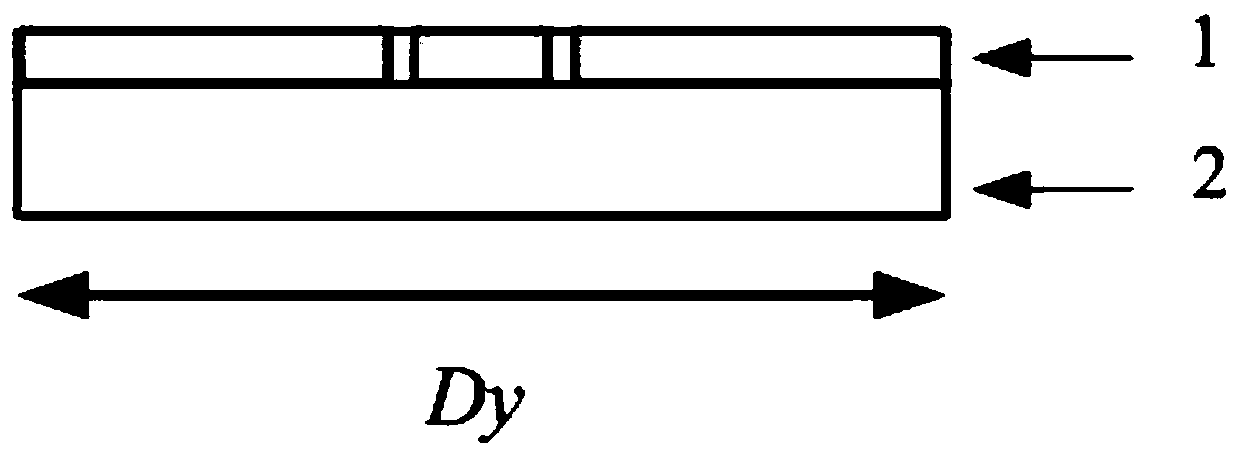

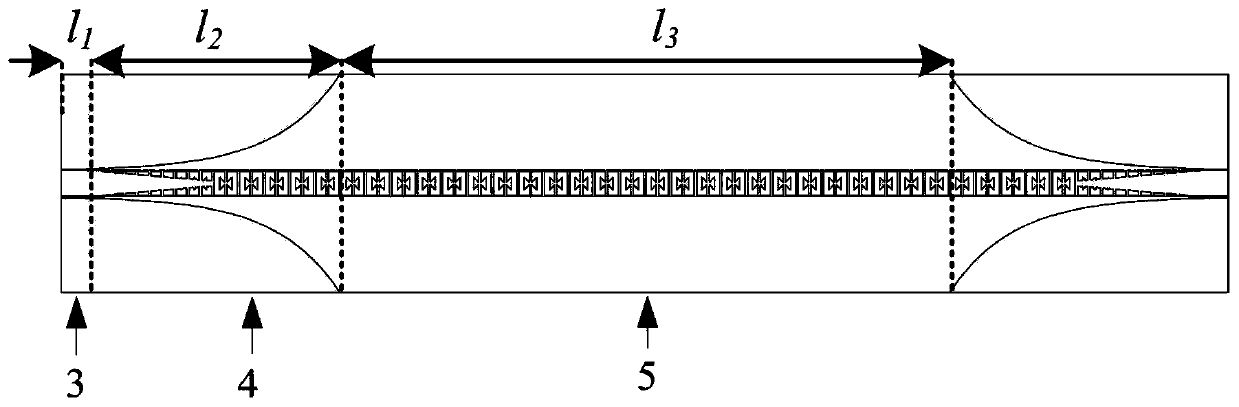

[0029] This embodiment provides a compact X-shaped artificial surface plasmon waveguide, its left view and top view are as follows figure 1 and figure 2 As shown, it is axisymmetrically distributed, including metal copper clad layer 1 and dielectric layer 2; the thickness of the metal copper clad layer is 0.035mm, the relative dielectric constant of the dielectric layer is equal to 2.67, and the thickness is 0.5mm, D y =41.52mm.

[0030] From left to right, the metal copper cladding is the first coplanar waveguide 3, the first transition structure 4, the X-shaped SSPPs structure 5 arranged periodically, the second transition structure and the second coplanar waveguide, where l 1 = 5mm, l 2 =50mm, l 3 =120mm.

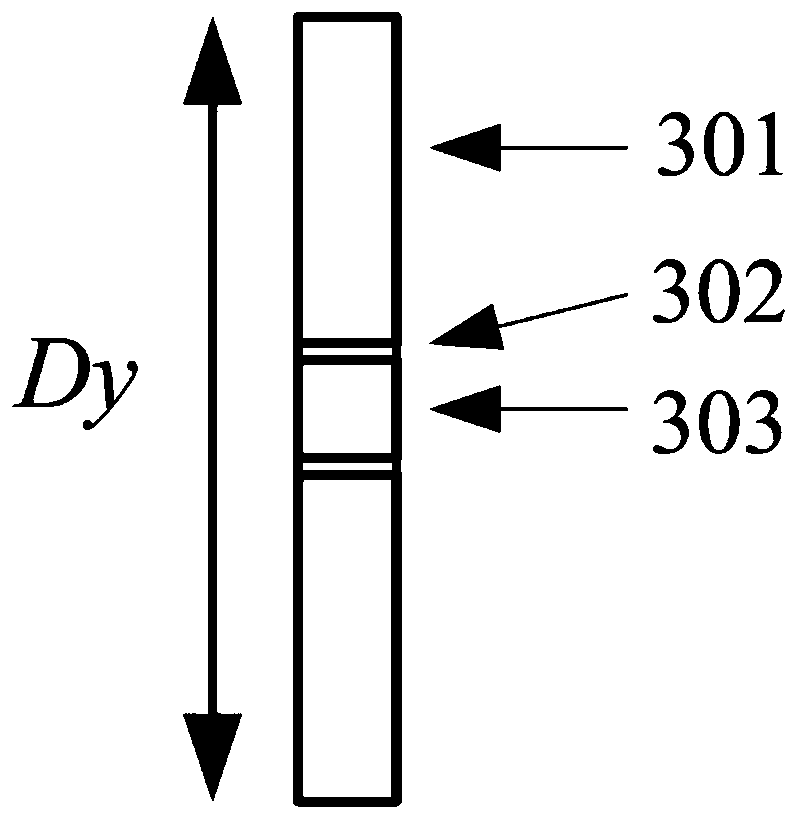

[0031] The coplanar waveguide is a 50Ω coplanar waveguide, and its structure diagram is as follows image 3 As shown, from top to bottom a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com