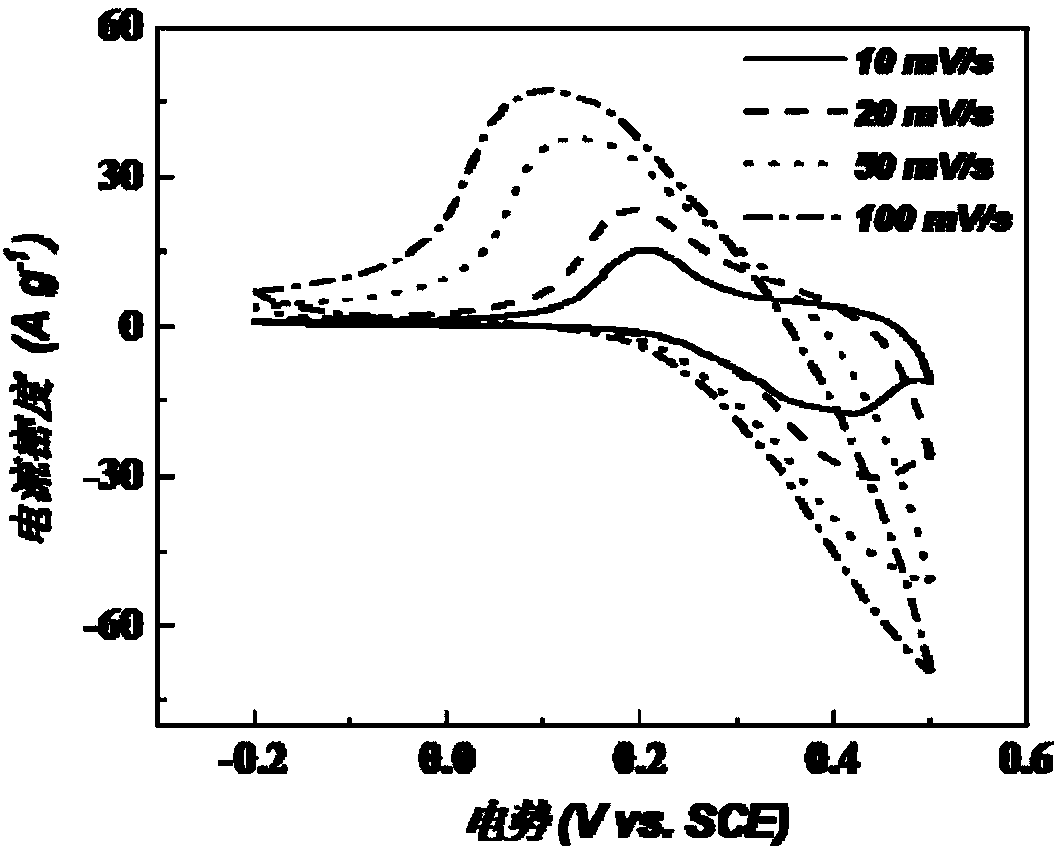

Carbon nano tube-cobalt tetrasulfide and nickel composite material, preparation method and application thereof

A technology of dicobalt tetrasulfide and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the conductivity cannot meet the high current density of supercapacitors, and the rate performance Inadequate, large capacity loss and other problems, to achieve good cycle stability, improve rate performance, weaken the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) Dissolve 0.16g of cetyltrimethylammonium bromide in a mixed solution of 30ml of deionized water and 120ml of ethanol, add 1.5ml of ammonia water and 0.1g of hydroxylated carbon nanotube powder, and mix in a beaker , Ultrasonic dispersion for 40min. Then 1ml of n-methylsilane (TEOS) was added dropwise, and magnetically stirred for 6h at a speed of 60r / min. Then the product was filtered and washed, and dried at 60°C for 12 hours to obtain CNT@SiO 2 .

[0034] (2) Take 30 mg of the powder material prepared in the previous step, put it into a glass bottle with a blue cap, add 40 ml of deionized water, and disperse it by ultrasonic for 40 min. Then add 1g of urea and 1ml of 0.1mol / L Ni(NO 3 ) 2 and 2ml of 0.1mol / L Co(NO 3 ) 2 The solution was magnetically stirred for 5 minutes, the bottle was tightly sealed, and the reaction was carried out by hydrothermal reaction at 105°C for 12 hours. Then cool naturally, wash the obtained product by suction filtration, and dry ...

Embodiment 2

[0042] (1) Dissolve 0.2g cetyltrimethylammonium bromide in a mixed solution of 30ml deionized water and 120ml ethanol, add 1.5ml ammonia water and 0.1g hydroxylated carbon nanotube powder, and mix in a beaker , Ultrasonic dispersion for 40min. Then 1ml of n-methylsilane (TEOS) was added dropwise, and magnetically stirred for 6h at a speed of 60r / min. Then the product was filtered and washed, and dried at 60°C for 12 hours.

[0043] (2) Take 30 mg of the powder material prepared in the previous step, put it into a glass bottle with a blue cap, add 40 ml of deionized water, and disperse it by ultrasonic for 40 min. Then add 2g ammonia water and 1ml 0.1mol / L Ni(NO 3 ) 2 and 2ml of 0.1mol / L Co(NO 3 ) 2 The solution was magnetically stirred for 5 minutes, the bottle was tightly sealed, and the reaction was carried out by hydrothermal reaction at 105°C for 12 hours. Then cool naturally, filter and wash the obtained product, and dry at 60°C for 12h.

[0044] (3) Take 10 mg of ...

Embodiment 3

[0046] (1) Dissolve 0.16g of octadecyltrimethylammonium bromide in a mixed solution of 30ml of deionized water and 120ml of ethanol, add 1.5ml of ammonia water and 0.1g of hydroxylated carbon nanotube powder, and mix in a beaker , Ultrasonic dispersion for 40min. Then 1ml of n-methylsilane (TEOS) was added dropwise, and magnetically stirred for 6h at a speed of 60r / min. Then the product was filtered and washed, and dried at 60°C for 12 hours.

[0047] (2) Take 30 mg of the powder material prepared in the previous step, put it into a glass bottle with a blue cap, add 40 ml of deionized water, and disperse it by ultrasonic for 40 min. Then add 1g of urea and 1ml of 0.1mol / L Ni(NO 3 ) 2 and 2ml of 0.1mol / L Co(NO 3 ) 2 The solution was magnetically stirred for 5 minutes, the bottle was tightly sealed, and the reaction was carried out by hydrothermal reaction at 105°C for 12 hours. Then cool naturally, filter and wash the obtained product, and dry at 60°C for 12h.

[0048] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com