Transition metal oxide carbon nanotube composite material and its preparation method and application

A technology of carbon nanotubes and transition metals, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of electrochemical performance cycle stability, unsatisfactory rate performance, and poor conductivity. Achieve the effects of improving cycle performance and stability, cycle performance, and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 0.04g hydroxylated carbon nanotubes, 1.2mmol ferric nitrate, 10mmol urea, 0.11mmol cetyltrimethylammonium bromide, 2mmol glucose, add 75mL ethanol-water solution (the volume ratio of ethanol and water is 1:2) Ultrasonic dispersion for 40 minutes after mixing;

[0031] (2) Transfer the system prepared in step (1) to a hydrothermal kettle for hydrothermal synthesis reaction, wherein the reaction temperature is 190°C, and the reaction time is 12h;

[0032] (3) The reaction system obtained in step (2) was left to stand, centrifuged and washed to neutrality, and dried at 60° C. in air for 12 hours to finally obtain a carbon-coated iron oxide carbon nanotube composite material.

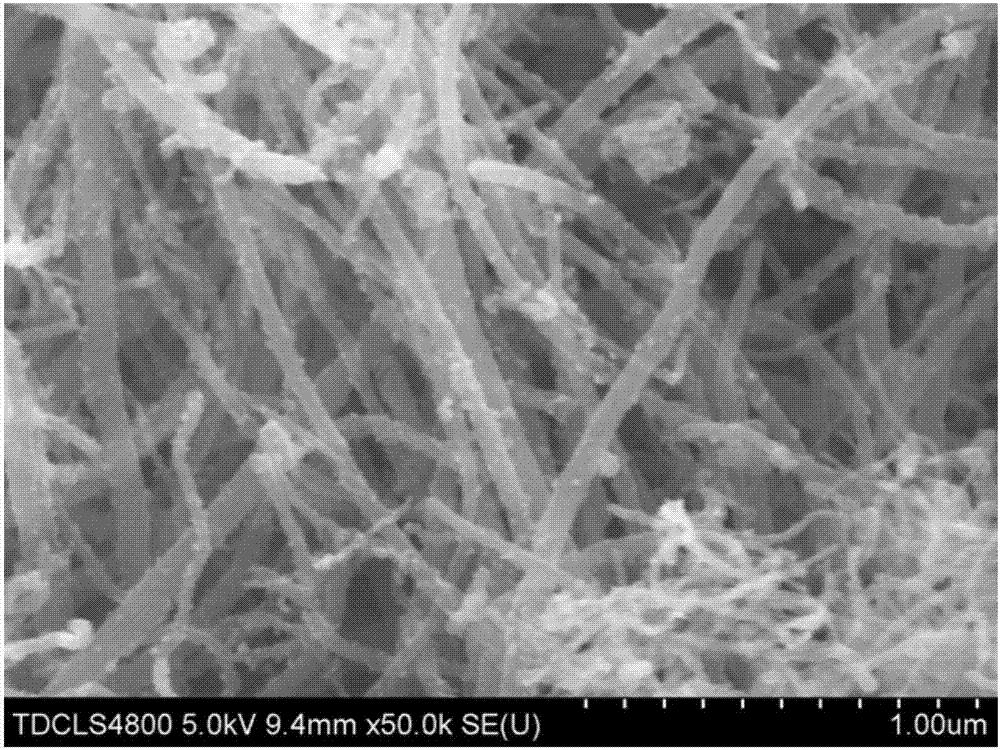

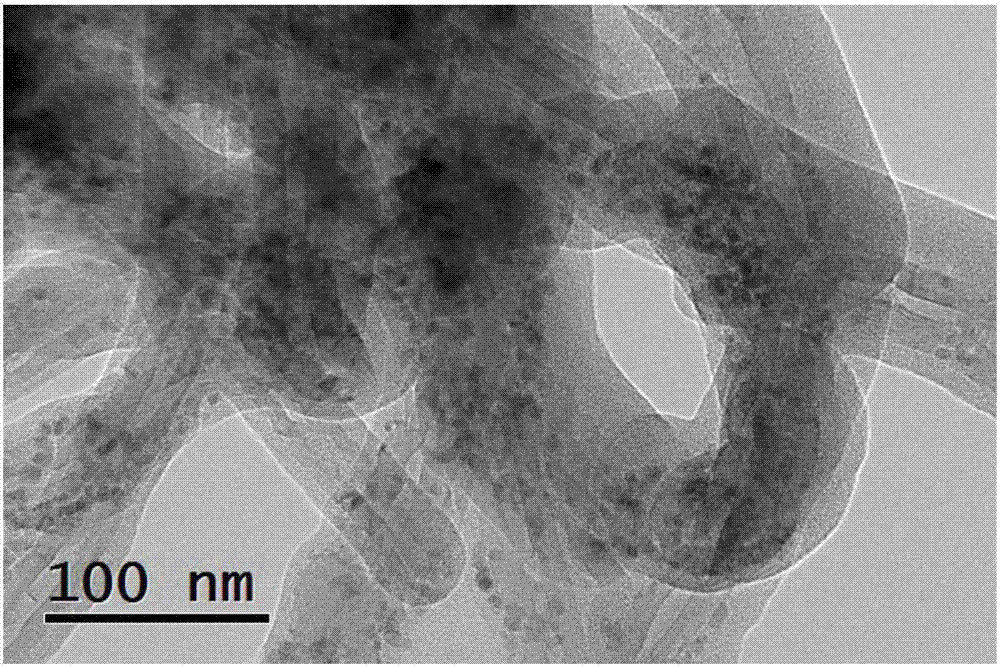

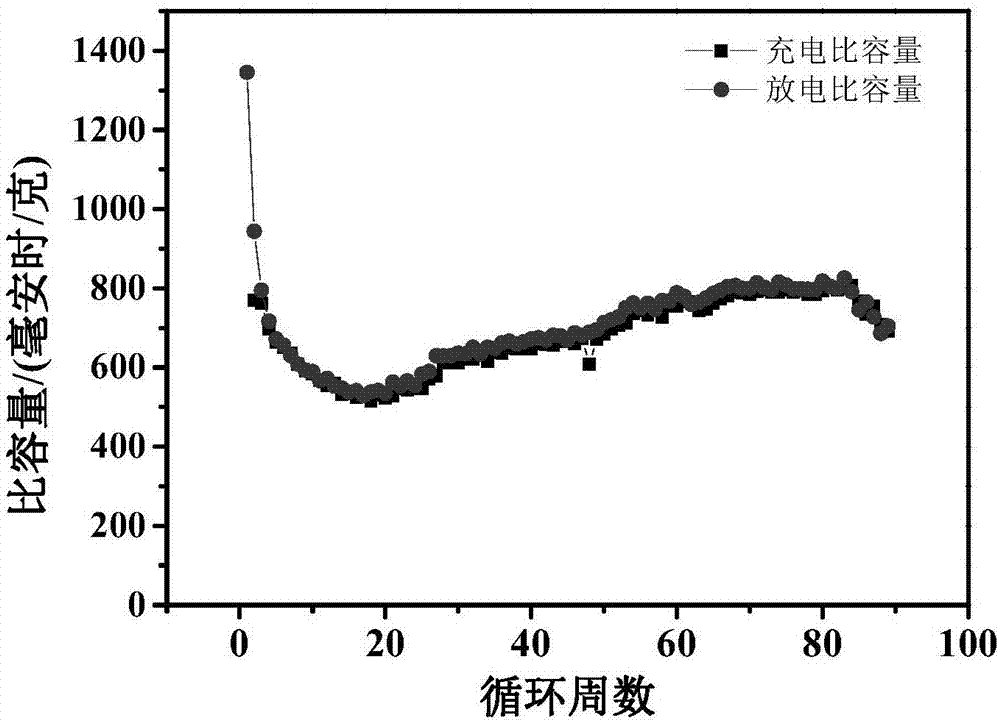

[0033] figure 1 It is the low-magnification SEM image of the iron oxide carbon nanotube composite material coated with carbon obtained in Example 1. It can be seen that the total diameter of the nanotubes obtained is close to 50nm, which is far greater than the diameter of the carbon nanot...

Embodiment 2

[0037] (1) Weigh 0.04g hydroxylated carbon nanotubes, 1.2mmol cobalt nitrate, 10mmol urea and 0.11mmol cetyltrimethylammonium bromide, add 75mL ethanol-water solution (the volume ratio of ethanol and water is 1:2 ) ultrasonically disperse for 40 minutes after mixing;

[0038] (2) Transfer the system prepared in step (1) to a hydrothermal kettle for hydrothermal synthesis reaction, wherein the reaction temperature is 190°C, and the reaction time is 24h;

[0039] (3) The system obtained from the reaction in step (2) is left to stand, centrifuged and washed to neutrality, and dried at 60°C for 12 hours in air to finally obtain a cobalt oxide carbon nanotube composite material;

[0040] Figure 4 It is a low-magnification SEM image of the cobalt oxide carbon nanotube composite material obtained in Example 2. It can be seen that the surface of the carbon nanotube is uniformly coated with a layer of cobalt oxide, and the total diameter is between 30nm and 100nm.

Embodiment 3

[0042] (1) Utilize the carbon nanotube film synthesized by floating catalytic chemical vapor deposition method, refer to the Chinese patent whose publication number is CN103031624A for details, wash and dry with sufficient amount of aqua regia for 12h~36h, and obtain the carbon nanotube film treated with aqua regia ;

[0043] (2) Weigh 0.04g of aqua regia-treated carbon nanotube membrane, 1.2mmol of ferric nitrate, 10mmol of urea and 0.11mmol of cetyltrimethylammonium bromide, add 75mL of ethanol aqueous solution (the volume ratio of ethanol and water is 1 :2) Ultrasonic dispersion for 40min after mixing;

[0044] (3) Transfer the system prepared in step (1) to a hydrothermal kettle for hydrothermal synthesis reaction, wherein the reaction temperature is 190°C, and the reaction time is 12h;

[0045](4) The reaction system obtained in step (2) is left to stand, washed until neutral, and dried at 60° C. for 12 hours to finally obtain the iron oxide carbon nanotube membrane comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com