Seawater and sea sand concrete column

A technology of concrete column and sea sand, applied in the field of concrete, can solve the problems of excessive crack width and deflection of brittle failure characteristics, reduce concrete mixing cost, material brittleness and high price, achieve high cost performance, improve bearing capacity, prevent Corrosive outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

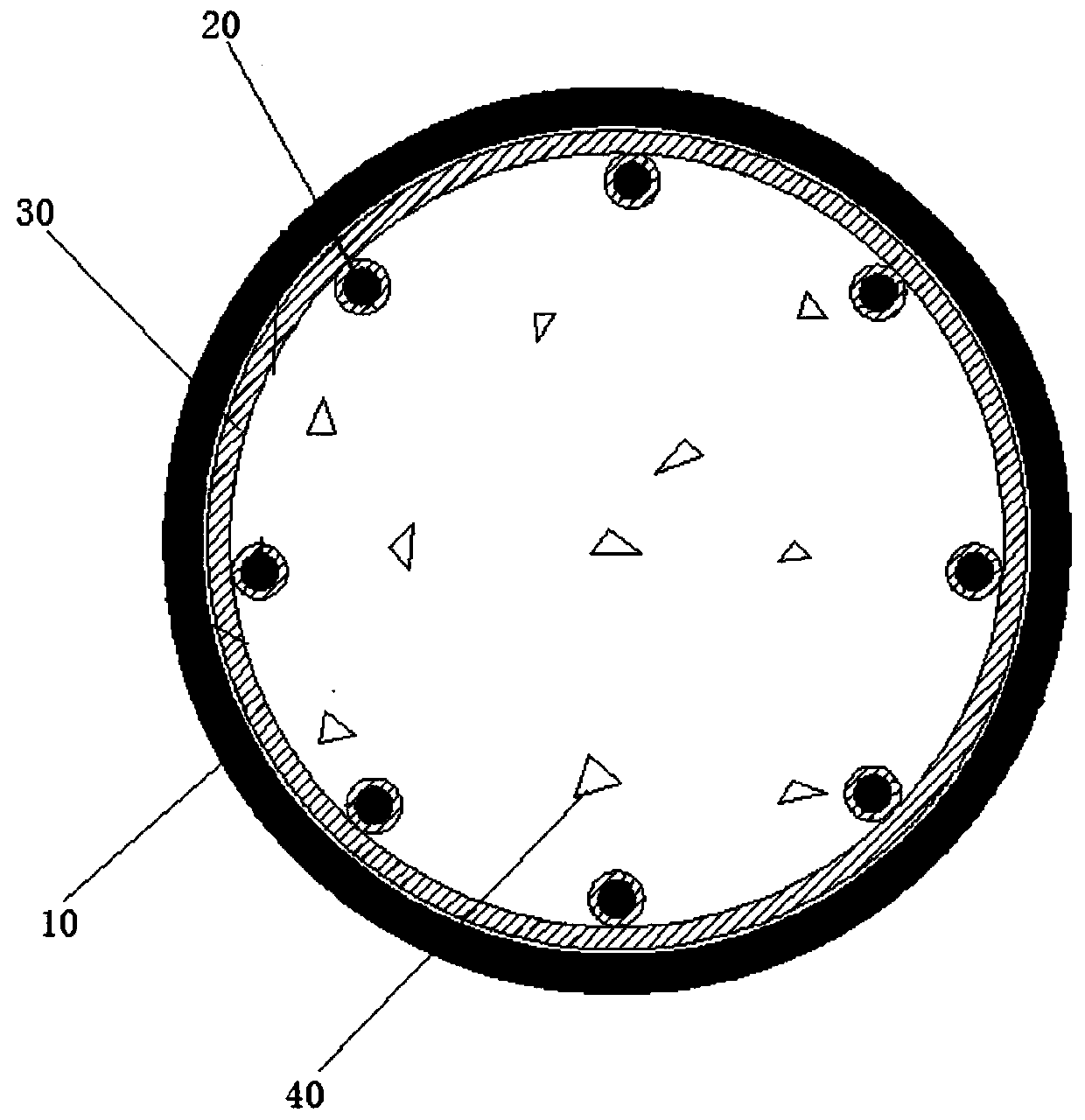

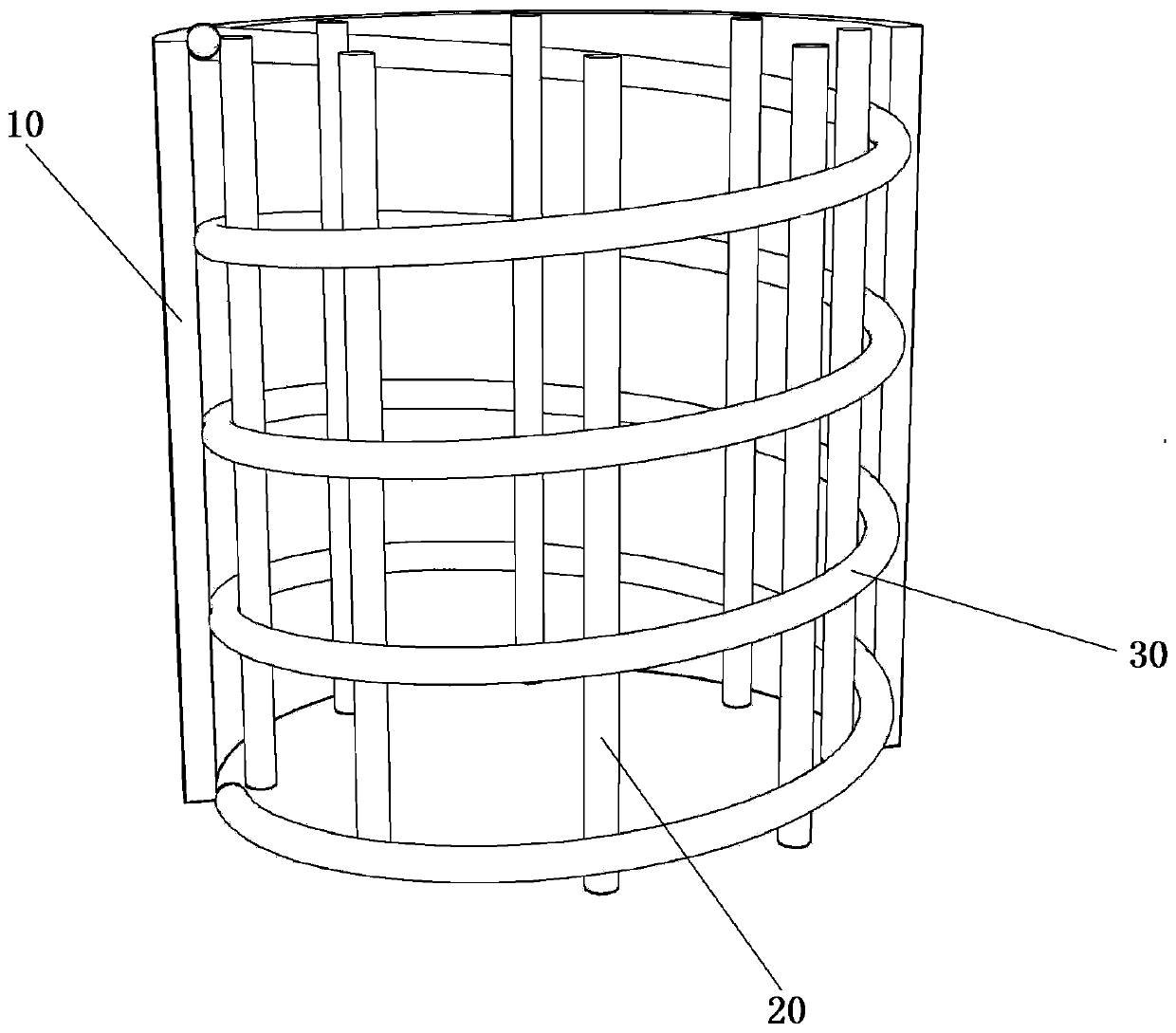

[0027] Such as figure 1 and figure 2 The shown seawater sea sand concrete column is embodiment 1 of the present invention, a kind of seawater sea sand concrete column, comprises polyethylene pipe 10 and several FRP-steel composite bars 20, and described several FRP-steel composite bars 20 vertical Arranged in the polyethylene pipe 10 to the ground, the several FRP-steel composite bars 20 are evenly arranged along a circumferential direction, and the FRP-steel composite bars 20 are provided with FRP-steel composite stirrups 30. The polyethylene pipe 10 is filled with concrete 40, and the concrete 40 is composed of sea sand, sea water, cement and coarse aggregate.

[0028] It can be seen from the above that the present invention uses the outer polyethylene pipe and the inner FRP-steel composite bar to jointly restrain the concrete composed of sea sand and sea water, the bearing capacity of the concrete column is improved, the ductility and earthquake resistance are improved, a...

Embodiment 2

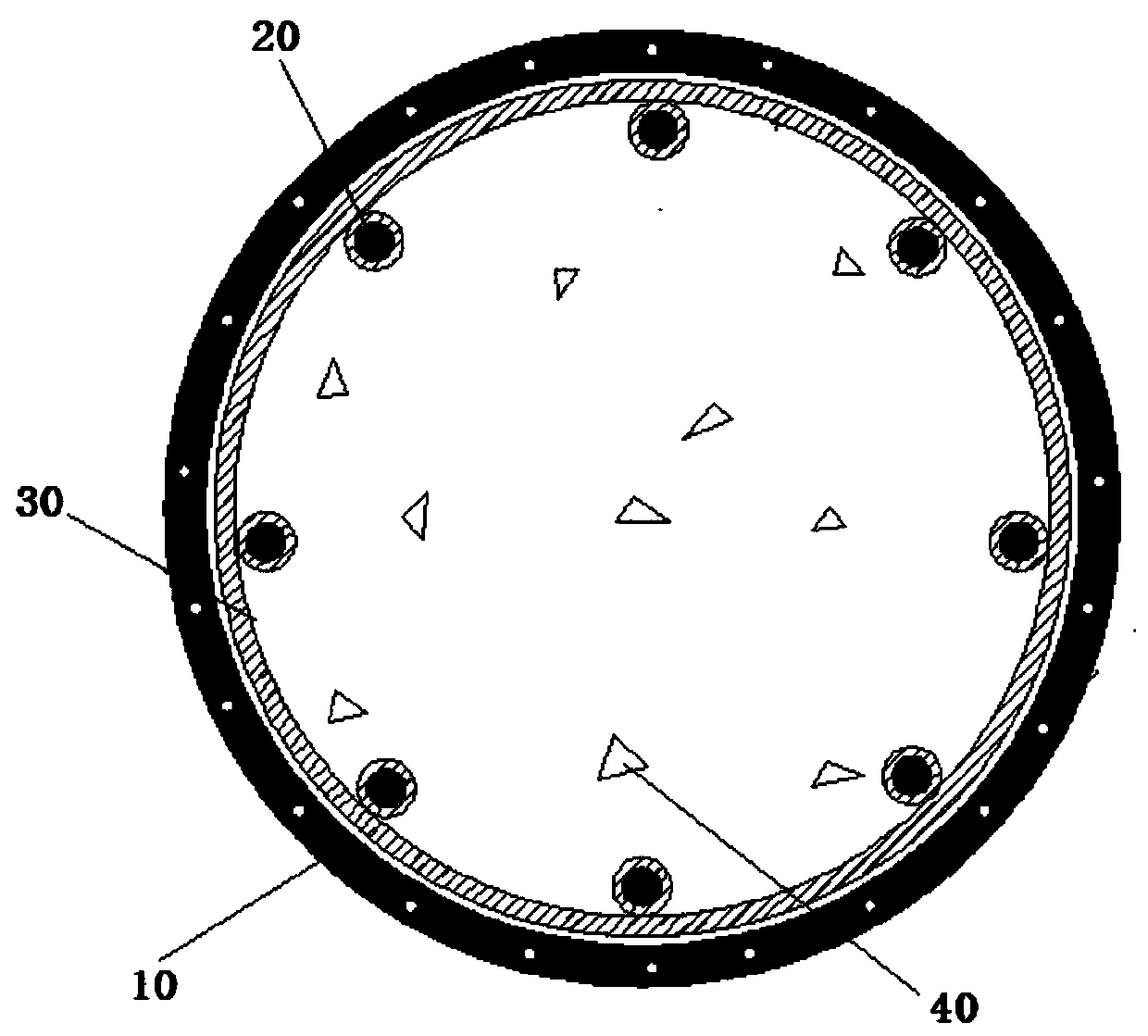

[0040] Such as image 3 and Figure 4 The shown seawater sea sand concrete column is embodiment 2 of the present invention, and it differs from embodiment 1 in that the FRP-steel composite stirrup 30 is a ring-shaped stirrup, and the number of the ring-shaped stirrup is There are several circular stirrups distributed from bottom to top and fixedly connected with FRP-steel composite bars 20 . The ring-shaped stirrup is fixedly connected with the FRP-steel composite bar, which is more tightly combined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com