Processing method for reinforcing aroma of rapeseed oil and rapeseed oil

A processing method, rapeseed oil technology, applied in the direction of edible oil/fat, fat oil/fat production, fat production, etc., can solve the problems of less loss of biologically active substances, cumbersome production process, high oil yield, etc., and achieve the reduction of aroma substances The effect of loss, strong flavor and clear color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present embodiment provides a kind of processing method and rapeseed oil of strengthening rapeseed oil flavor, and this method comprises the following steps:

[0055] Step 1: Selection of raw materials: select fresh rapeseed with full grains and no mildew as raw materials;

[0056] Step 2: crushing: crushing the rapeseed obtained in step 1 through a grinder and collecting the crushed rapeseed powder, wherein the crushing degree is 20-40 mesh;

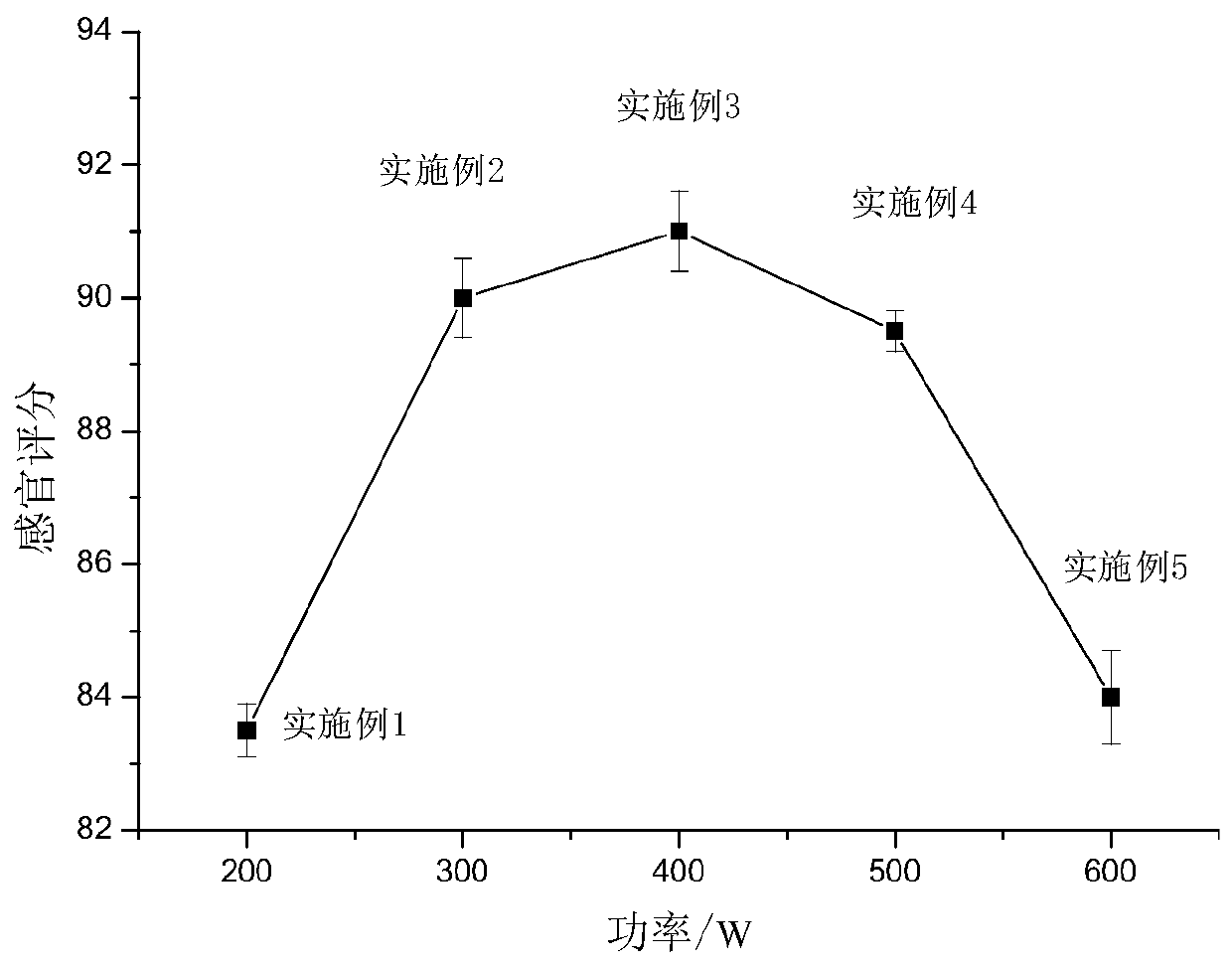

[0057] Step 3: microwave treatment: microwave the rapeseed powder obtained in step 2, wherein the microwave power is 200W, and the microwave treatment time is 2 minutes;

[0058] Step 4: Dry steaming: dry-steam the rapeseed powder obtained by microwave treatment in step 3, collect the steam distilled during the dry steaming process, and obtain a condensate after the steam is condensed; wherein, dry steaming is to dry the microwave-treated rapeseed powder Put the seed powder into the distillation bottle separately for distill...

Embodiment 2

[0062] This example provides a processing method for enhancing the aroma of rapeseed oil and rapeseed oil. The difference between this example and Example 1 is that the microwave power in Step 3 is 300W, and other raw materials and experimental conditions are the same.

Embodiment 3

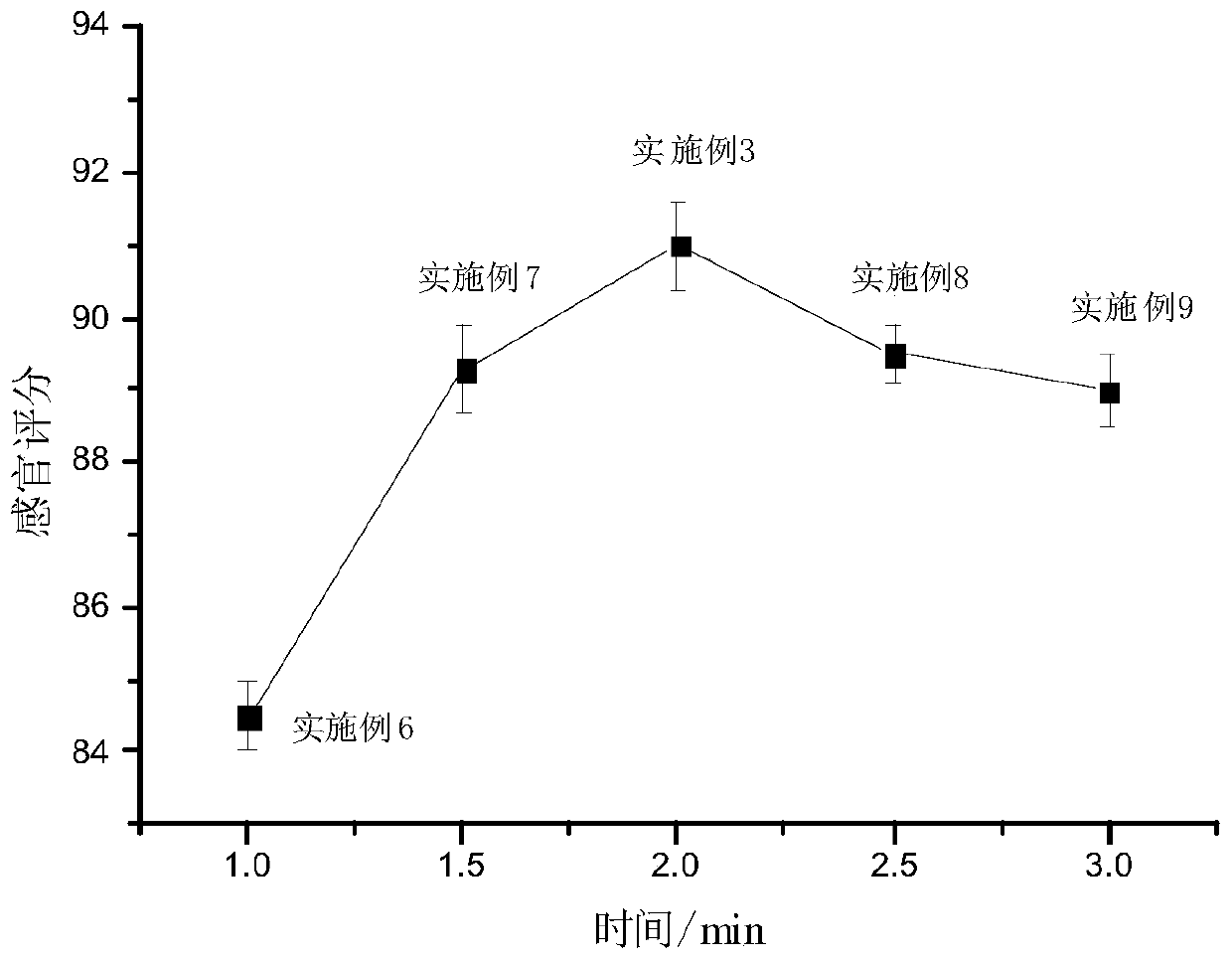

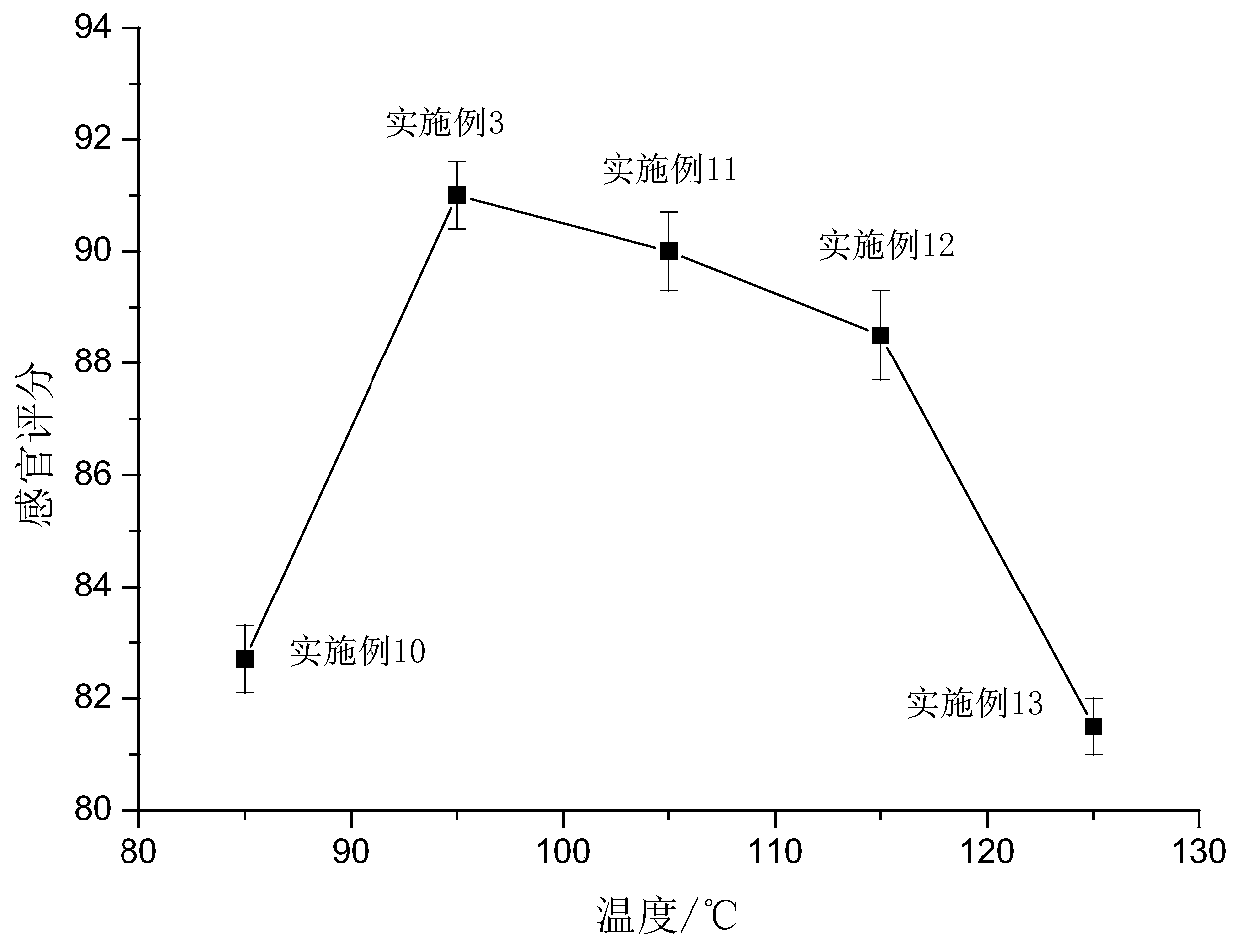

[0064] This example provides a processing method for enhancing the aroma of rapeseed oil and rapeseed oil. The difference between this example and Example 1 is that the microwave power in Step 3 is 400W, and other raw materials and experimental conditions are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com