Preparation method of high fluorescence efficiency Cs2AgxNa1-xInncl6 dual-layer perovskite

A double-layer perovskite, high-efficiency technology, applied in chemical instruments and methods, luminescent materials, nanotechnology for materials and surface science, etc. Fluorescence yield, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

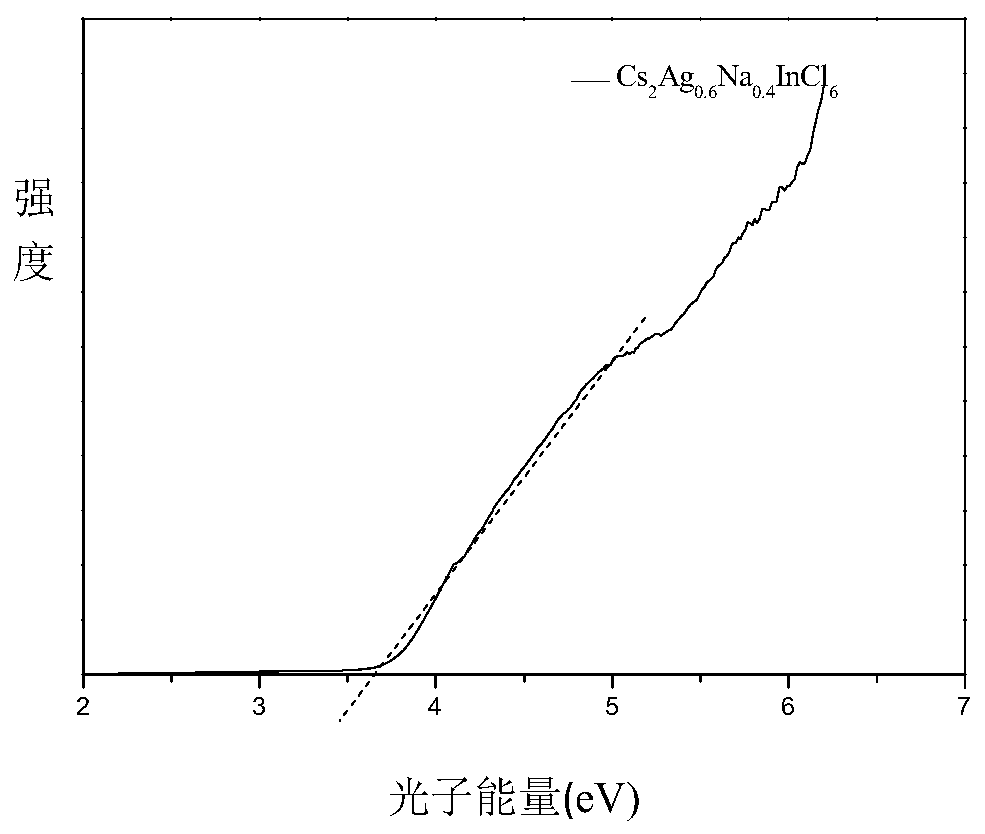

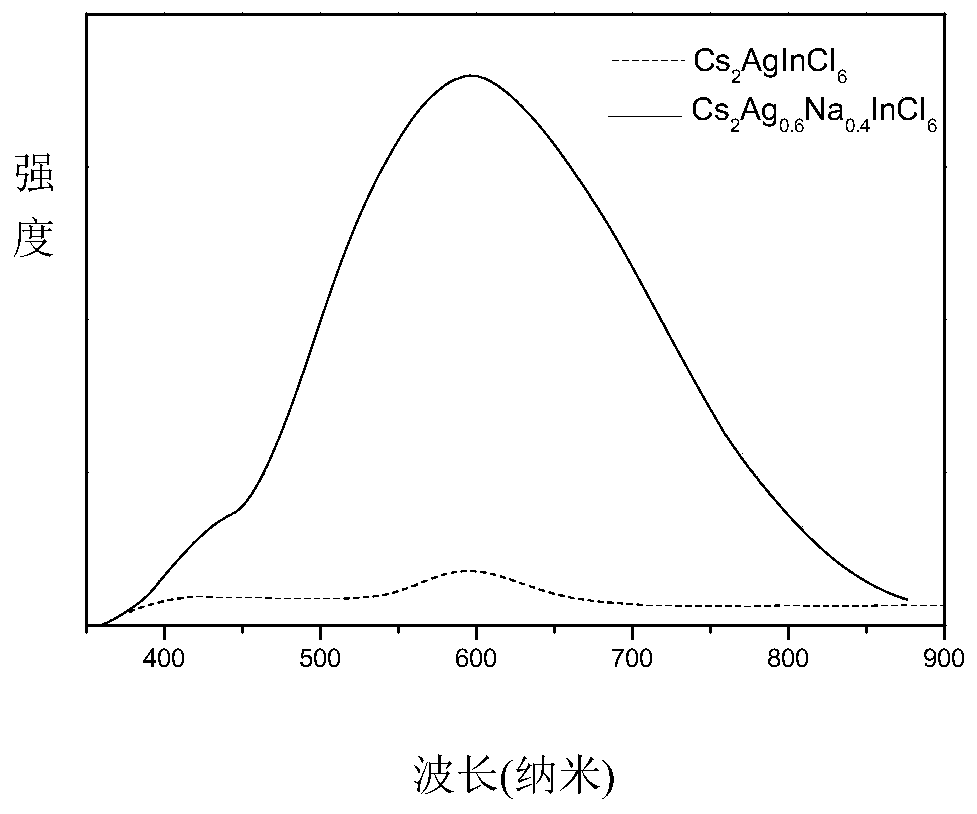

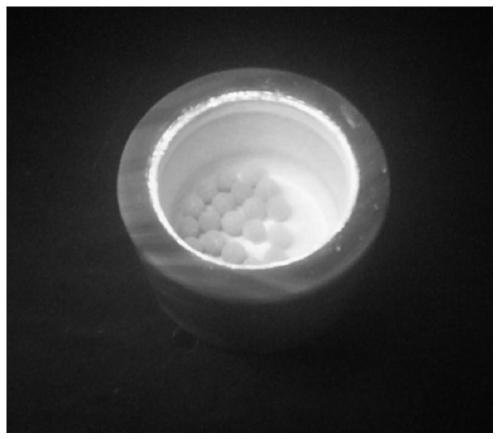

[0021] Put 1mmol indium chloride, 2mmol cesium chloride, 0.4mmol sodium chloride, 0.9mmol silver chloride and 25 agate balls with a diameter of 6mm into a 25ml agate jar, adjust the AC frequency of the ball mill to 40Hz, and the speed at this time is 1200rad / min, mechanically milled for 1.5 hours, the mixture gradually hardened from a fluffy white powder and adhered to the wall of the agate jar, then became soft again, and finally became a fluffy powder again to obtain Cs 2 Ag 0.6 Na 0.4 InCl 6 Double-layer perovskite, then add 0.005mmol of bismuth chloride to it, continue to grind for 5 minutes, bismuth chloride is evenly dispersed in the system, at this time, irradiate with a 305nm ultraviolet lamp, it is found that the fluorescence brightness of the product does not continue to increase, and the The resulting product was washed twice with ethanol to remove unreacted cesium chloride and indium chloride, and then dried in a vacuum oven at 60° C. for two hours. The product w...

Embodiment 2

[0023] Change the consumption of the sodium chloride in embodiment 1 into 0.1mmol, 0.2mmol, 0.3mmol, 0.5mmol, 0.6mmol, 0.7mmol, 0.8mmol, 0.9mmol respectively by 0.4mmol and keep the content of sodium chloride and silver chloride simultaneously The total amount of moles is 1mmol constant, other conditions and steps are constant, and the fluorescent quantum efficiency of the product obtained from the consumption of different sodium chloride is as follows: Figure 4 As shown, the fluorescence efficiency of each product is 25.2%, 43.5%, 64.2%, 88.2%, 73.5%, 48.2%, 27.3%, 16.3%, respectively, Figure 5 The XRD patterns of the products obtained with some representative sodium chloride dosages are given.

Embodiment 3

[0025] The amount of sodium chloride is 0.5mmol, and the temperature after the final drying is changed from 60°C to 180°C, 240°C, and 350°C respectively, and the fluorescence quantum efficiencies of the products obtained at different temperatures are 88.7%, 90.2%, and 88.3% respectively. %. It shows that the heat treatment at 180~350℃ helps to improve the fluorescence yield of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com