Preparation method of nitrogen-doped porous carbon material and application of nitrogen-doped porous carbon material in super capacitor

A nitrogen-doped porous carbon, supercapacitor technology, applied in the field of electrochemical energy storage, can solve the problems of difficult structure regulation, difficult template removal, complex synthesis process, etc., to achieve high energy density, improve hydrophilicity, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

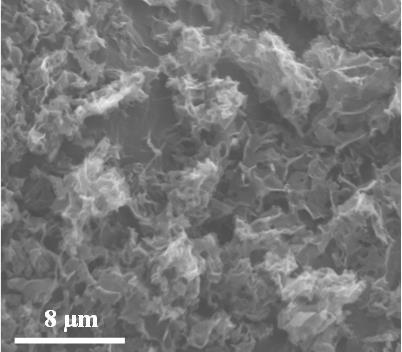

[0031] Example 1. Preparation of nitrogen-doped porous carbon materials.

[0032] (1) Dissolve 0.6 g of sodium alginate, 0.6 g of sodium citrate dihydrate, and 0.8 g of melamine in 40 mL of water. Placed in a ball mill jar with a volume of 100 mL, ball milled at 400 rpm for 4 h and mixed evenly. Freeze-dried, wait until material A.

[0033] (2) Material A was calcined at 600°C for 2 hours in a nitrogen atmosphere, cooled to room temperature, washed several times with 1 M hydrochloric acid and deionized, and dried at 80°C for 3 hours to obtain material B.

[0034] (3) Material B and KOH were mixed at a mass ratio of 1:1 and calcined at 800°C for 2 hours in a nitrogen atmosphere, then cooled to room temperature, washed with 1 M hydrochloric acid and deionized several times, and dried at 80°C for 3 hours to obtain nitrogen doped porous carbon material.

Embodiment 2

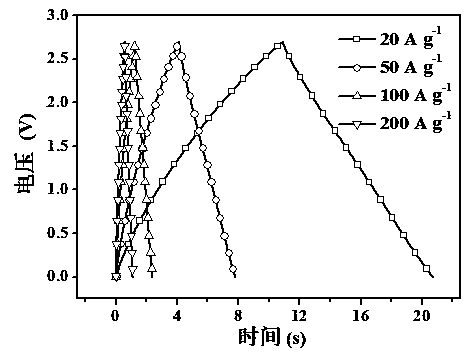

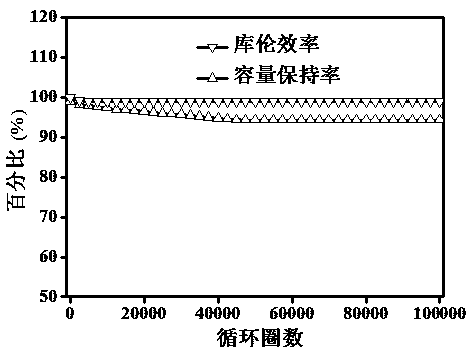

[0035] Example 2. Applications of nitrogen-doped porous carbon materials in supercapacitors.

[0036] (1) Mix the prepared nitrogen-doped porous carbon material with a binder and a conductive agent at a mass ratio of 8:1:1, coat it on a nickel foil with a thickness of 0.03 mm, and then dry it in vacuum to obtain a supercapacitor electrode piece.

[0037] (2) Pole sheets coated with nitrogen-doped porous carbon materials are used as both positive and negative electrodes, EMIMBF 4 As the electrolyte and cellulose acetate as the separator, a symmetrical soft-pack supercapacitor is assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com